High-efficiency lanolin recovering method and device

A recovery device and lanolin technology, applied in the field of high-efficiency lanolin recovery, can solve the problems of large loss of lanolin, low extraction rate, and inability to perform good control, and achieve the effect of reducing loss and increasing extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

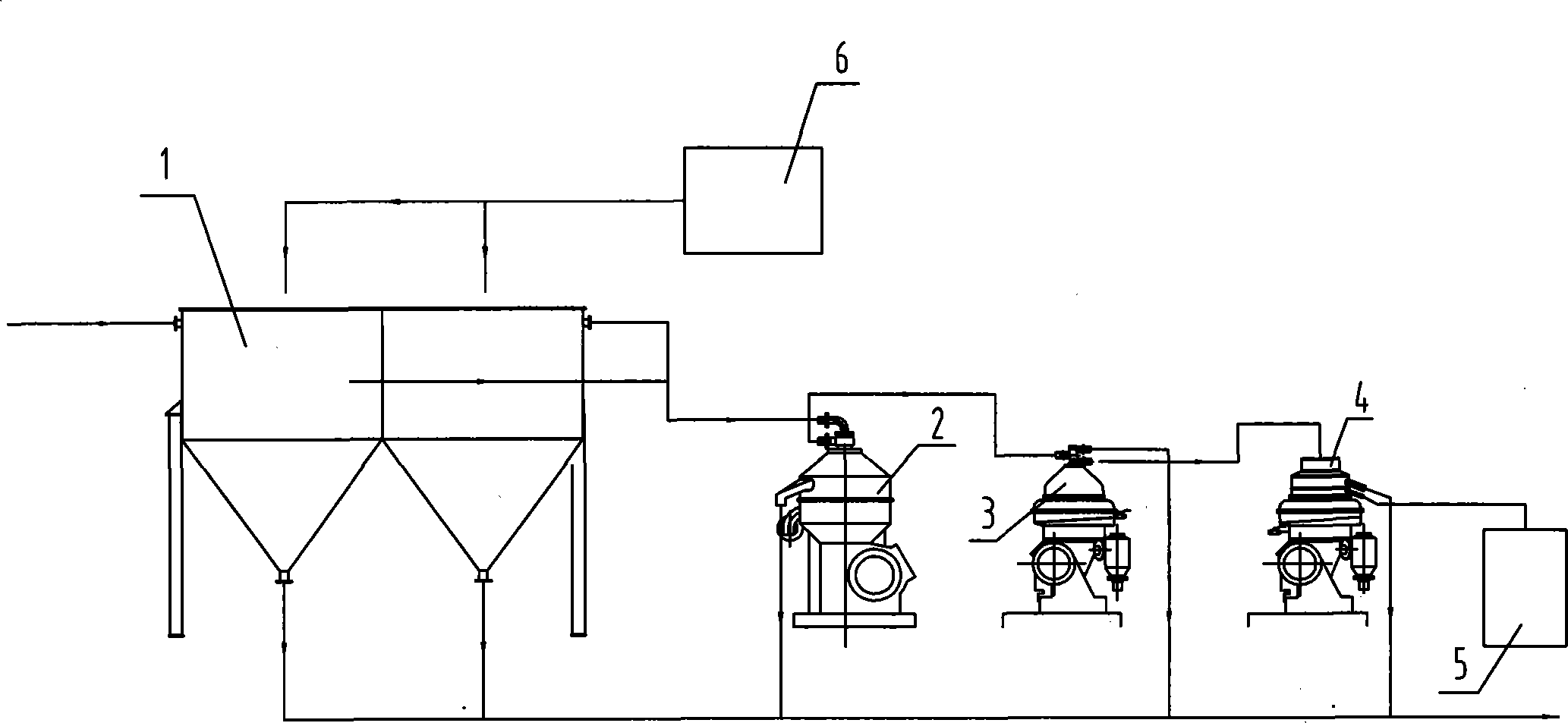

[0026] This embodiment is a high-efficiency lanolin recovery method, which is carried out in the following steps:

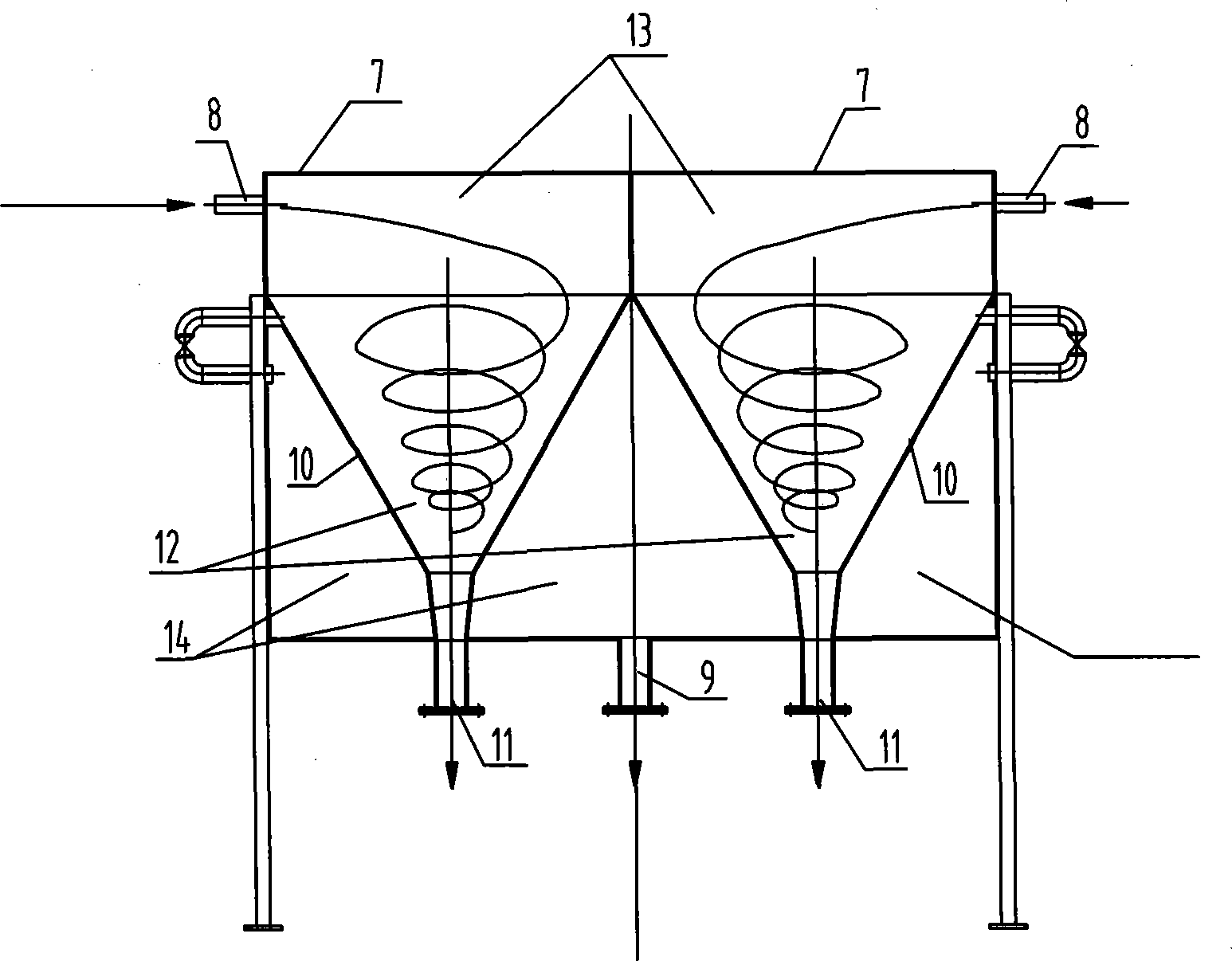

[0027] (1) After dehairing the wool scouring wastewater containing lanolin, the demulsification, cooking and desilting treatments are alternately completed in the cooking box. The lanolin-containing wastewater is first added with a demulsifier in the inlet pipe, and then the swirl washing process, cooking process and precipitation process are completed in the cooking box; the swirl washing process is completed by a tangential jet or a cyclone; the cooking process uses steam cooking, The scouring wastewater is raised to 70°C; the sedimentation process is that the scouring wastewater is steamed and left for 30 minutes to settle, and the sedimented silt is discharged regularly. The silt in the scouring wastewater is highly viscous and cannot be completely separated by high-speed centrifugal separation technology. Separation, the silt can be effectively separated from t...

Embodiment 2

[0033] This embodiment is a high-efficiency lanolin recovery method, which is carried out in the following steps:

[0034] (1) After dehairing the wool scouring wastewater containing lanolin, the demulsification, cooking and desilting treatments are alternately completed in the cooking box. The lanolin-containing wastewater is first added with a demulsifier in the inlet pipe, and then the swirl washing process, cooking process and precipitation process are completed in the cooking box; the swirl washing process is completed by a tangential jet or a cyclone; the cooking process uses steam cooking, The scouring wastewater is raised to 80°C; the sedimentation process is that the scouring wastewater will stand for 35 minutes after cooking, and the sediment will be discharged regularly. The silt in the scouring wastewater has a high viscosity and cannot be completely removed by high-speed centrifugal separation technology. Separation, the silt can be effectively separated from the was...

Embodiment 3

[0039] This embodiment is a high-efficiency lanolin recovery method, which is carried out in the following steps:

[0040] (1) After dehairing the wool scouring wastewater containing lanolin, the demulsification, cooking and desilting treatments are alternately completed in the cooking box. The lanolin-containing wastewater is first added with a demulsifier in the water inlet pipe, and then the swirling process, cooking process and precipitation process are completed in the cooking box; the swirling process is completed by tangential jet or cyclone; the steaming process uses steam to make washing The wool wastewater rises to 90°C; the sedimentation process is that the wool scouring wastewater is boiled and left for 40 minutes to settle, and the sedimented silt is discharged regularly. The silt in the wool scouring wastewater is very viscous and cannot be completely separated by high-speed centrifugal separation technology. The swirling flow can first effectively separate the mud ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com