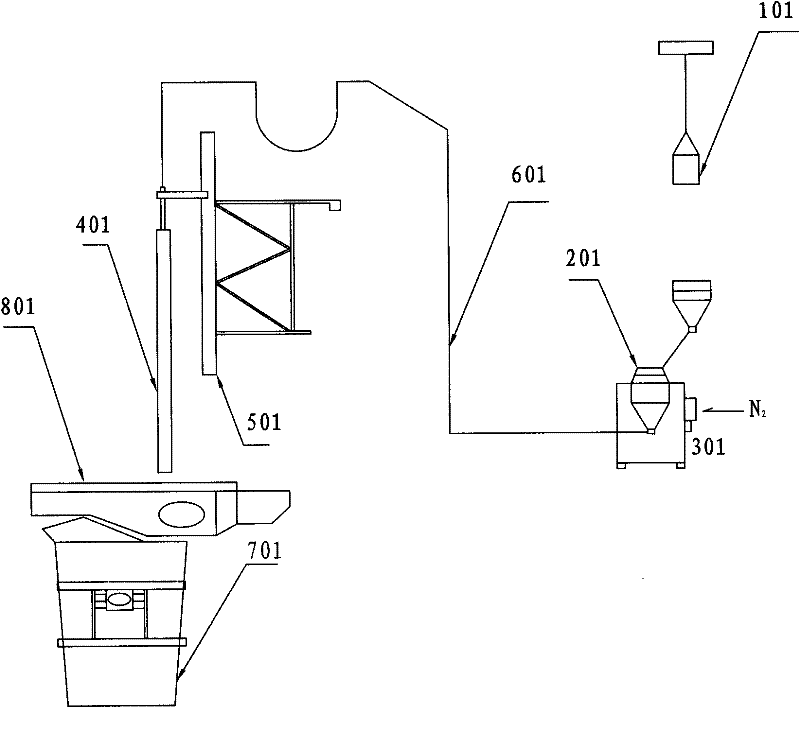

Refining method of molten iron in ladle and devices required by same

A technology of molten iron and equipment, which is applied in the field of molten iron refining in ladles, and can solve problems such as large iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

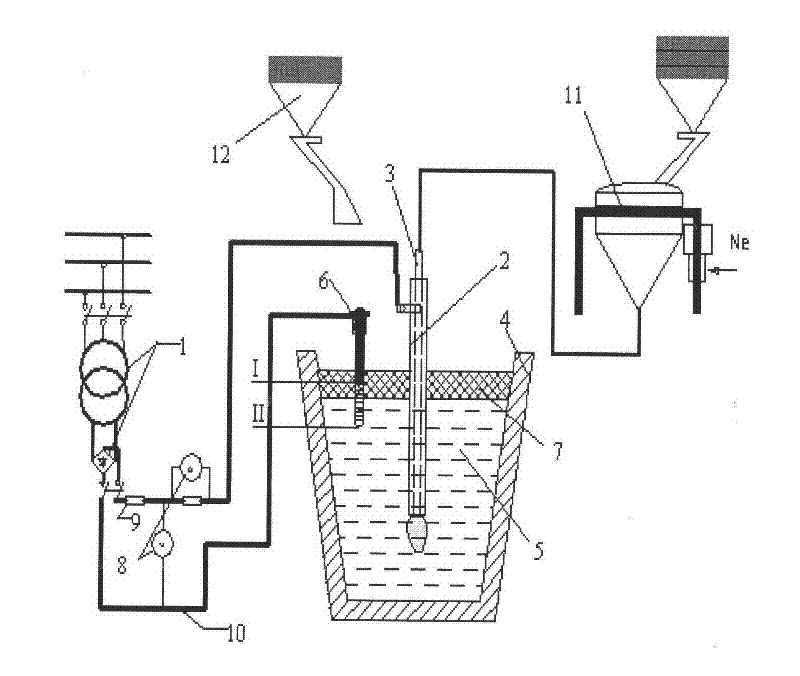

[0033] The present invention takes into account the characteristics of the desulfurization process in the molten iron ladle, that is, the gas jet is used to supply the desulfurizer. In addition to the conveying function, the jet also strengthens the stirring of the molten iron in the ladle, thereby speeding up the mass and heat exchange process and the refining process.

[0034] In order to solve this problem, this method is specially proposed, which includes using carrier gas jet to supply desulfurizer into molten iron through a submerged spray gun (inside the spray gun body-metal conduit). The Act differs in that:

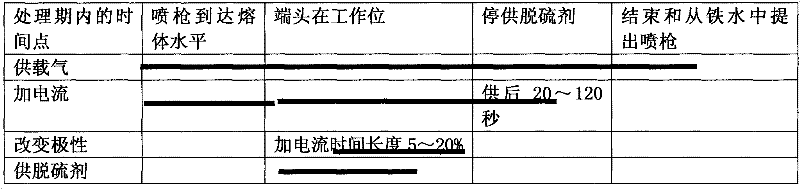

[0035] When desulfurization is carried out, a low-voltage potential is applied to the molten iron. The way to form the potential is to provide a current from one pole of the power supply to the molten iron space where the outlet of the spray gun is located through the spray gun, and from the other pole to pass through a conductive electrode (submerge it into the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com