A rheological in-situ online testing system integrating scattering and microscopy

An on-line testing, in-situ technology, applied in the micro-integrated rheological in situ on-line testing system, rheological performance on-line testing system, in the field of scattering, can solve the problem that the light scattering rheological testing system cannot be observed intuitively The microscopic morphology of the sample and the observation of the small-sized polymer structure are not obvious, so as to achieve the effect of a wide range of research contents and a large research scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

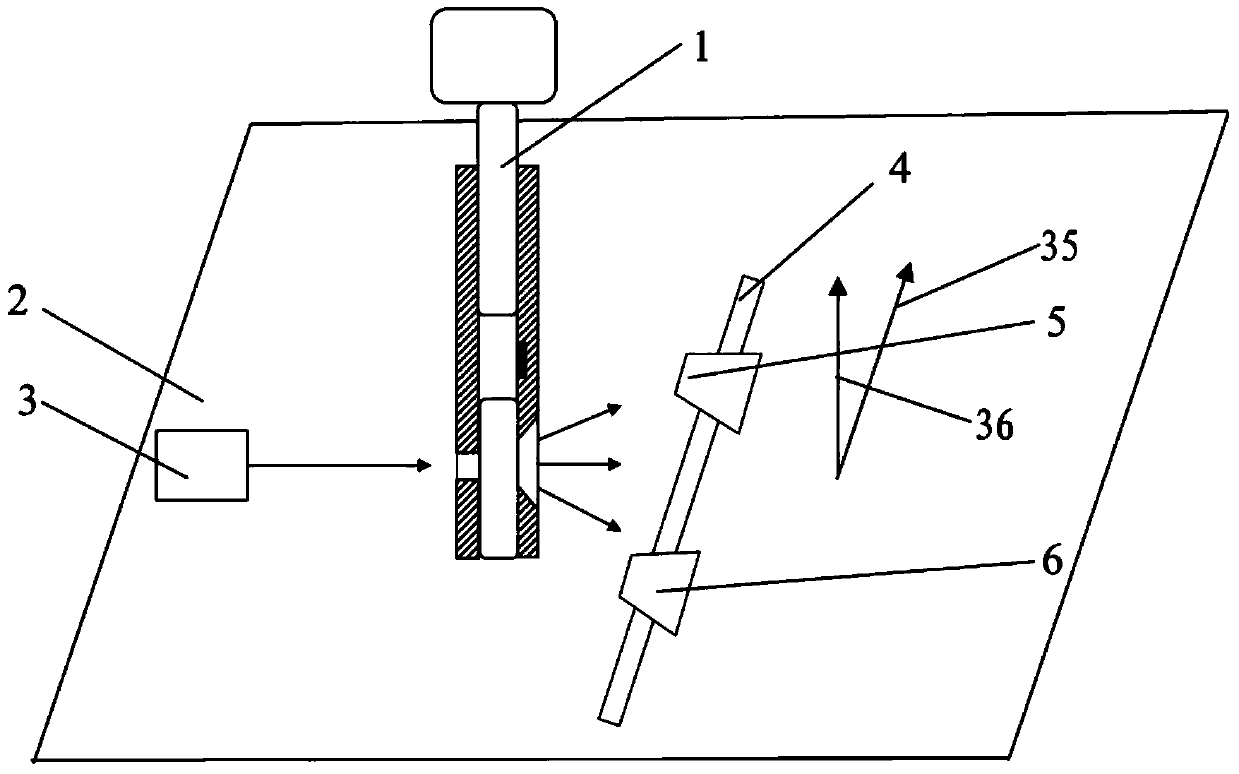

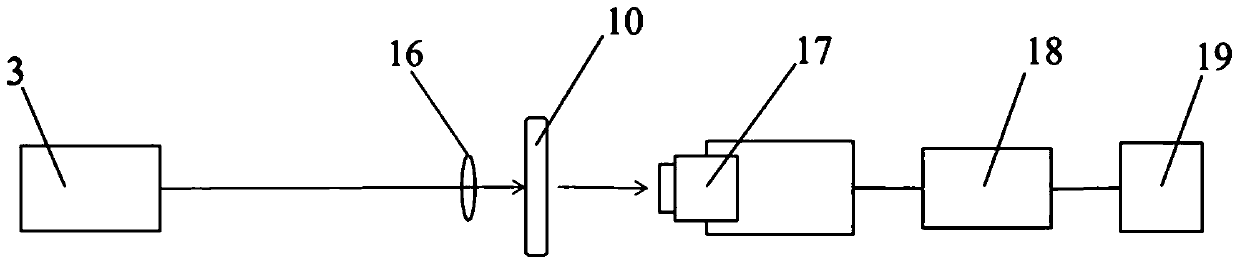

[0032] Reference attached figure 1 In the present invention, an in-situ online rheology test system integrating scattering and microscopy includes a capillary rheometer (1), a laser light source (3), a laser light scattering system (5) and a microscopic imaging system (6) , Are installed on the optical platform (2), the light scattering system (5) and the micro imaging system (6) share the flat-hole capillary (10) in the capillary rheometer (1), the light scattering system (5) and the display The micro imaging system (6) is installed on a high-precision optical system switching rail (4) on the optical platform (2), and the two systems are moved on the high-precision optical system switching rail (4) through computer software. Fast switching between laser light scattering optical path and microscope optical path.

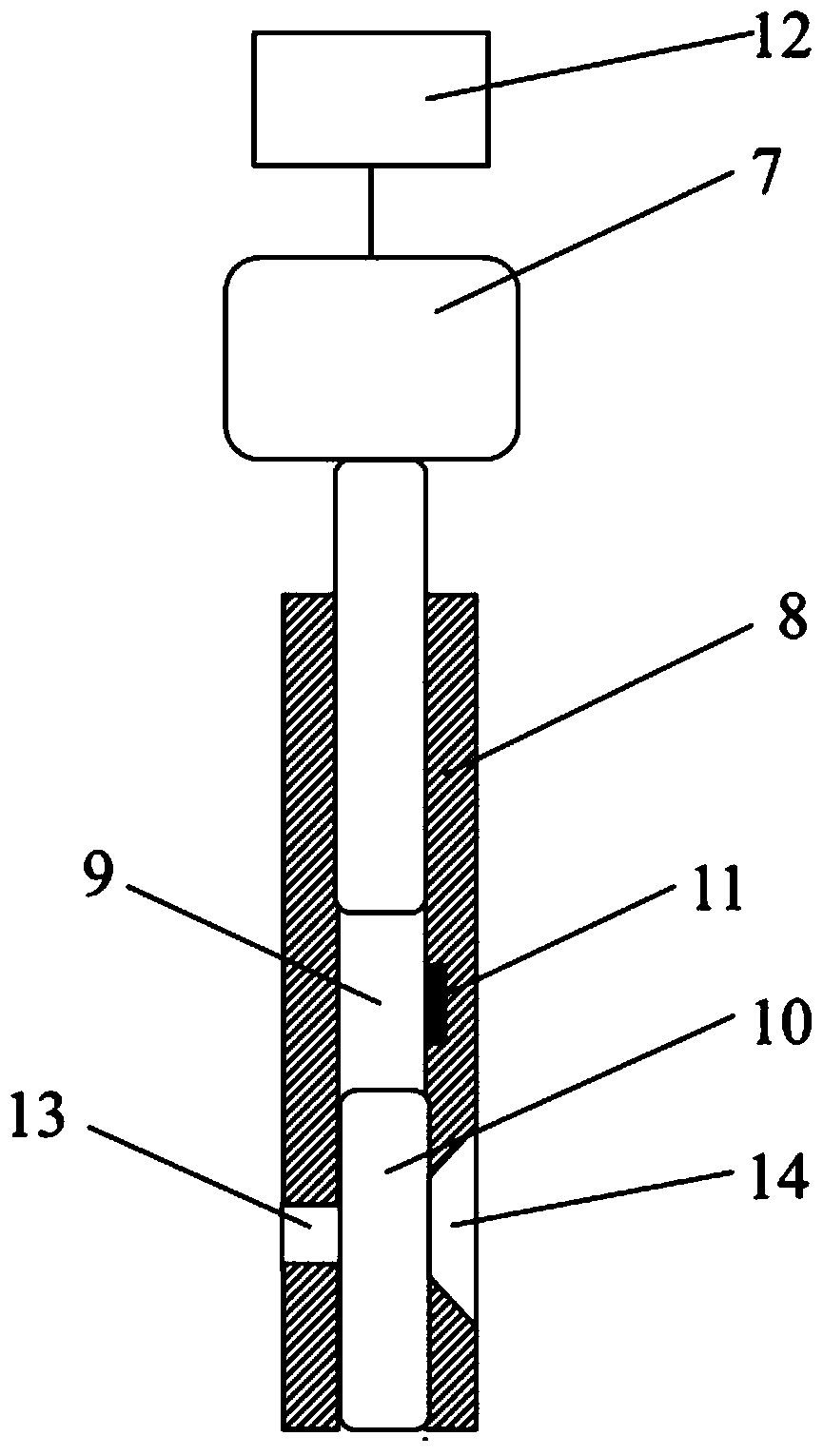

[0033] Reference attached figure 2 , The capillary rheometer (1) is composed of a controller (12), a plunger (7), an electric heating jacket (8), a barrel (9) and a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com