A roadway stacker for dense storage warehouses

A technology of stacker and storage warehouse, which is applied in the direction of storage device, transportation and packaging, etc. It can solve the problems of long telescopic distance of the fork, long time consumption, complex structure of the fork, etc., and achieves short traverse distance and low manufacturing cost. Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the examples do not constitute a limitation to the present invention.

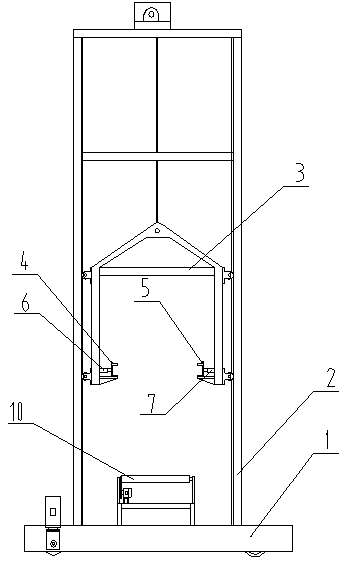

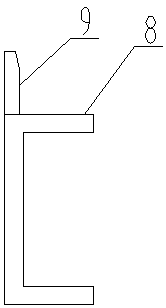

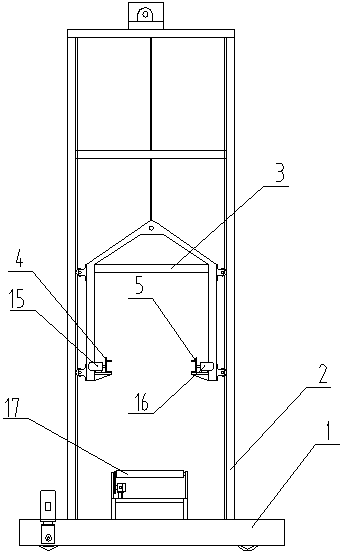

[0016] figure 1 and figure 2 It shows a first embodiment of the roadway stacker used in dense storage warehouses of the present invention, including a traveling trolley 1, a frame 2 vertically installed on the traveling trolley 1, and a lifting platform 3 that lifts along the frame 2, Shuttle car guide rail 4 is installed on the left side of lifting platform 3, and shuttle car guide rail 5 is installed on the right side, and the upper part of shuttle car guide rail is provided with the shelving surface 8 of goods, is provided with stopper 9 on the shelving surface 8, and the stopper 9 uses For the pushing and blocking of goods, the lifting platform 3 is also equipped with a traverse mechanism. The traverse mechanism is a cylinder 6 and a cylinder 7. The cylinder 6 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com