A processing method for forming patterns on velvet fabrics

A processing method and fabric technology, which are applied in the direction of fabric surface trimming, heating/cooling fabrics, textiles and papermaking, etc., can solve the problems of insufficient fluff and low three-dimensional layering of fluff, and achieve flexible patterns, low cost and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

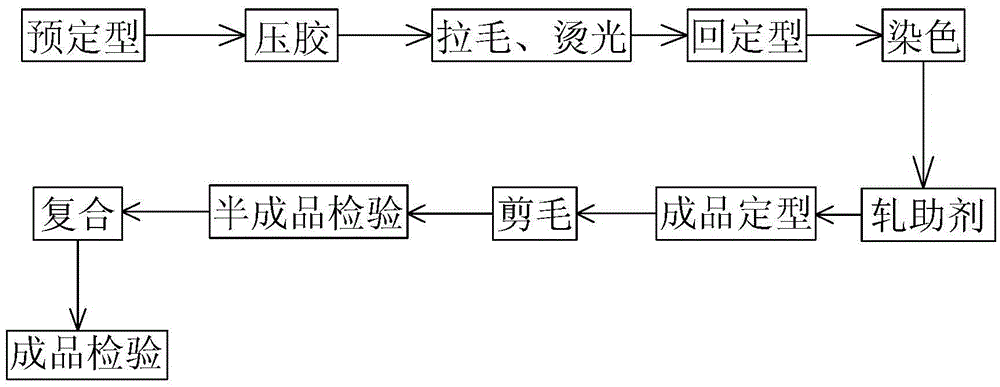

[0021] see figure 1 as shown, figure 1 It is a process flow chart of the processing method for forming a pattern on a velvet fabric provided in Embodiment 1 of the present invention.

[0022] In the present embodiment, on the high-speed tricot warp knitting machine whose machine number is E28 or E32, three or four guide bars are used to weave to form gray cloth. Yarn configuration: GB1 wears 75D144f polyester DTY, GB2 and GB3 wear 55D24f polyester FDY.

[0023] Laying weave raw material Warping piercing GB1:1-0 / 4-5 / / 75D144f polyester DTY 8×560 full wear GB2:1-0 / 1-2 / / 55D24f polyester FDY 8×560 full wear GB3:2-3 / 1-0 / / 55D24f polyester FDY 8×560 full wear

[0024] A method for processing velvet fabrics to form patterns, which includes the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com