Method for preparing modified biochar with aquatic plant waste and hematite

A technology of aquatic plants and hematite, which is applied in the field of biochar adsorption materials, can solve the problems of complex and expensive preparation methods, and achieve the effects of high adsorption performance, simple preparation methods, and excellent treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

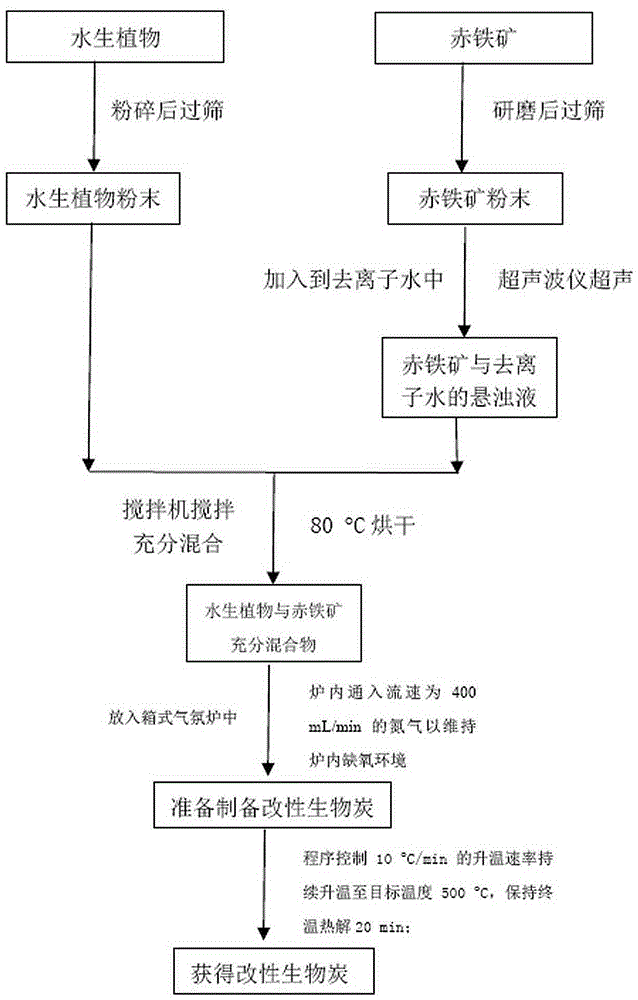

Method used

Image

Examples

Embodiment A

[0037] (1) Naturally air-dry the reeds so that the internal moisture content is lower than 10%, then pulverize them with a pulverizer and pass through a 100-mesh sieve to obtain reed powder.

[0038] (2) After the hematite is pulverized by a pulverizer, the hematite is pulverized by means of grinding with a mortar, and passed through a 100-mesh sieve to obtain hematite powder.

[0039] (3) Weigh 4g of hematite powder and put it into 100ml of deionized water, and after 1h of post-processing by an ultrasonic generator, a stable suspension is obtained.

[0040] (4) Weigh 40g of reed powder in step (1), soak it in the suspension described in step (3), and stir it for a certain period of time with a mixer, then dry it at 80°C to obtain reed and red Thorough mixture of iron ore.

[0041] (5) Weigh 100g of the reed and hematite mixture in step (4), place the mixed sample in a box-type atmosphere furnace, and feed nitrogen gas with a flow rate of 400mL / min into the furnace to maintai...

Embodiment A2

[0043] (1) Naturally air-dry the cattails so that the internal moisture content is lower than 10%, then pulverize them with a pulverizer and pass through a 100-mesh sieve to obtain cattail powder.

[0044] (2) After the hematite is pulverized by a pulverizer, the hematite is pulverized by means of grinding with a mortar, and passed through a 100-mesh sieve to obtain hematite powder.

[0045] (3) Weigh 4g of hematite powder and put it into 100ml of deionized water, and after 1h of post-processing by an ultrasonic generator, a stable suspension is obtained.

[0046] (4) Weigh 40g of cattail powder described in step (1), soak in the suspension described in step (3), and fully stir with a mixer for a certain period of time, then dry at 80°C to obtain cattail and red cattail Thorough mixture of iron ore.

[0047] (5) Weigh the full mixture of 100g of cattail and hematite described in step (4), place the mixed sample in a box-type atmosphere furnace, and feed nitrogen gas with a flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com