Object screening and receiving device and method

A technology for receiving devices and objects, applied in conveyor objects, chemical instruments and methods, filter screens, etc., can solve problems affecting machine productivity, good and bad, discontinuity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

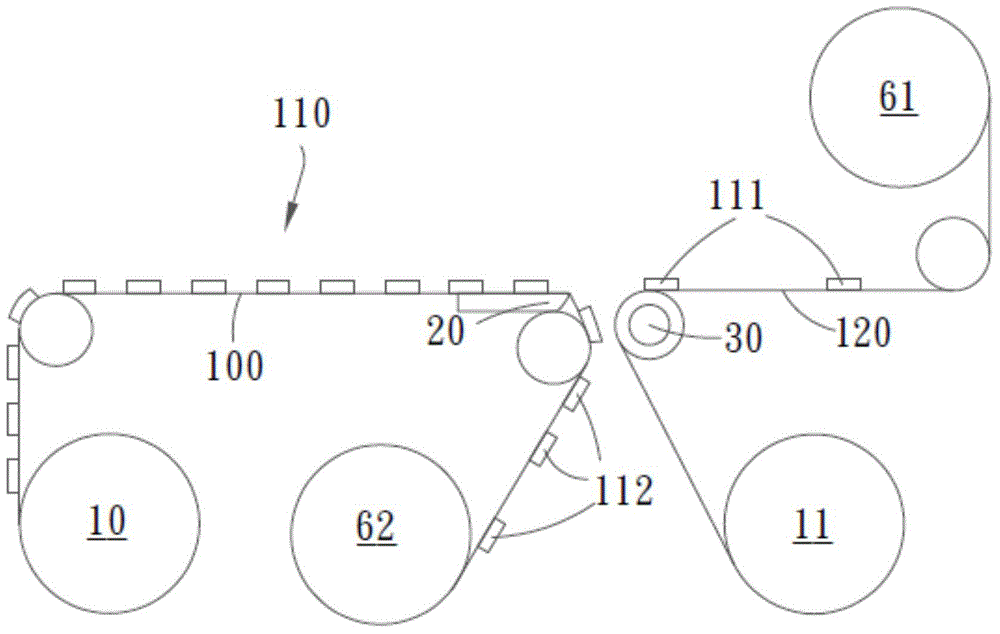

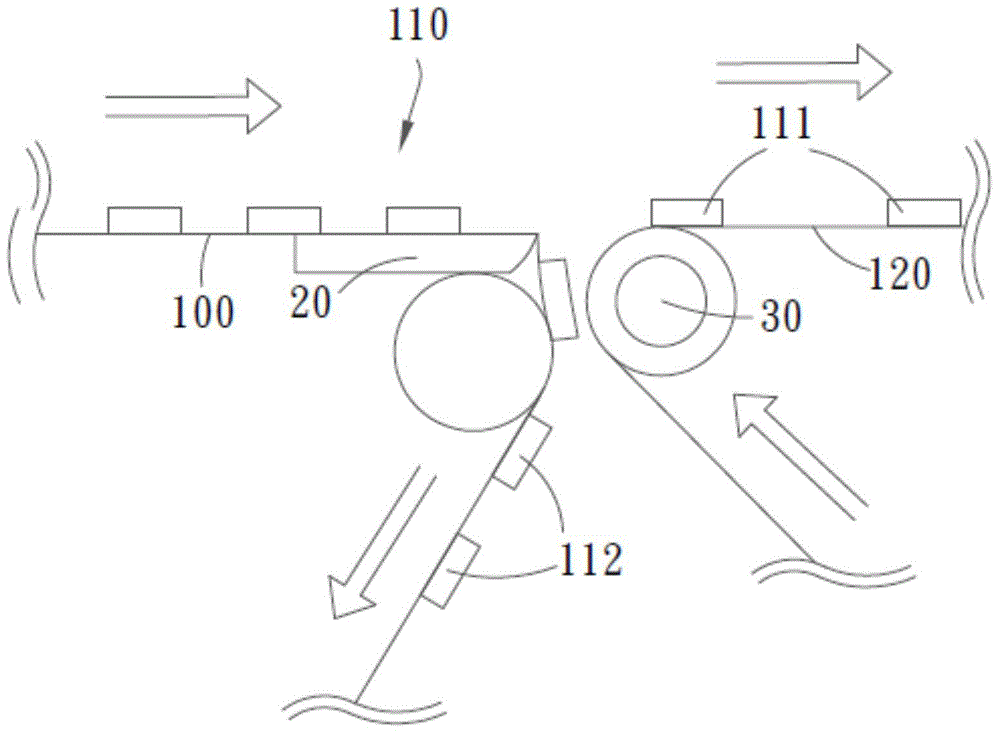

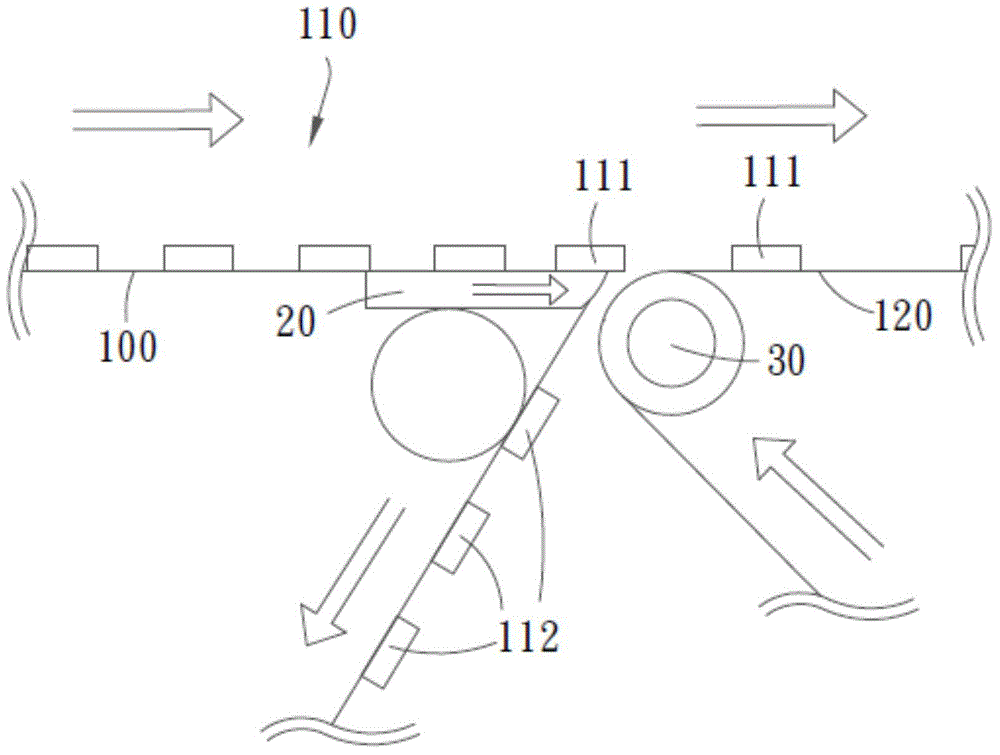

[0039] In order to make the structural features of the present invention and the achieved effects have a further understanding and recognition, preferred embodiments and detailed descriptions are specially used, which are described as follows:

[0040] An object screening and receiving device and its method of the present invention further improve the shortcomings of the conventional object classification technology. The conventional technology uses two mechanisms, which are respectively a good product receiving end and a defective material receiving end. , because it is necessary to classify the good and bad of multiple components on a discharge belt, the discharge belt needs to be decelerated to facilitate displacement, which will affect the production capacity of the machine, and this method requires many mechanisms to work at the same time. It also costs more. In addition, the conventional technology directly removes defective components, while the rest of the detected com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com