Sensor probe for measuring downhole rock electrical parameters

A technology of sensor probes and electrical parameters, applied in wellbore/well components, earthwork drilling, etc., can solve the problem that the resistivity and dielectric constant of core samples cannot be obtained in real time, the electrical parameters are insensitive to changes, and the electrical parameters of rocks cannot be measured, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

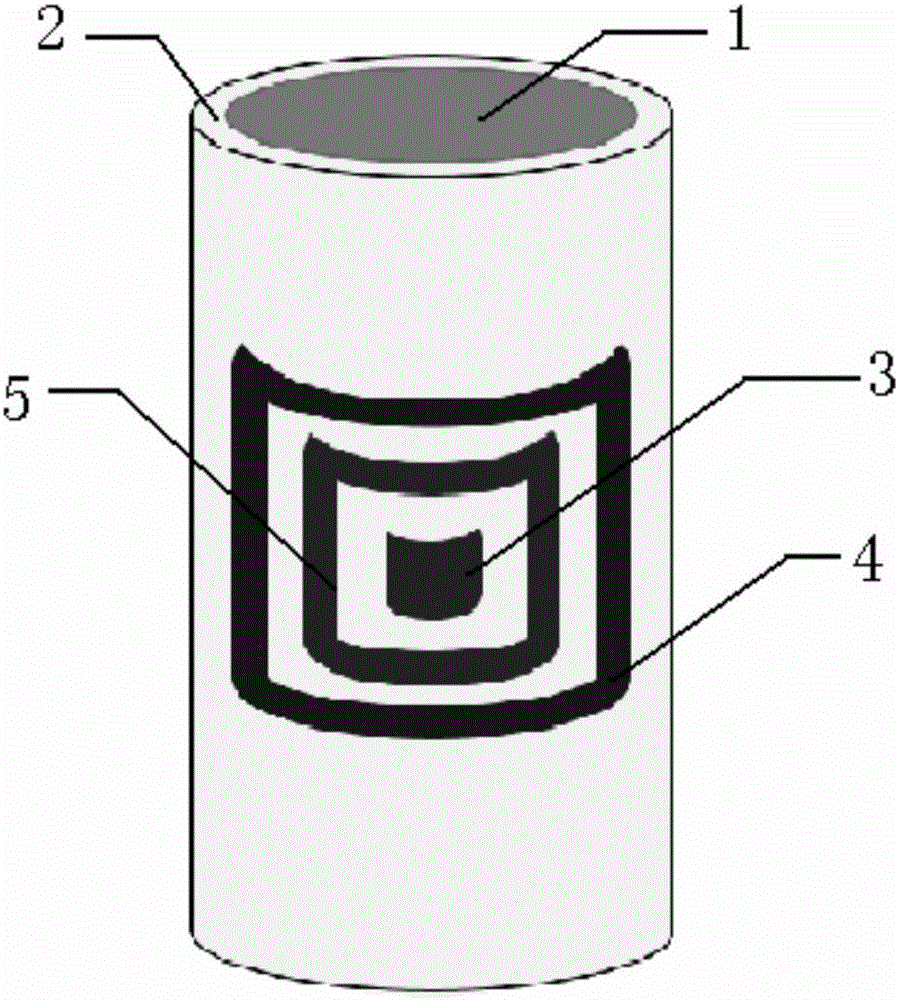

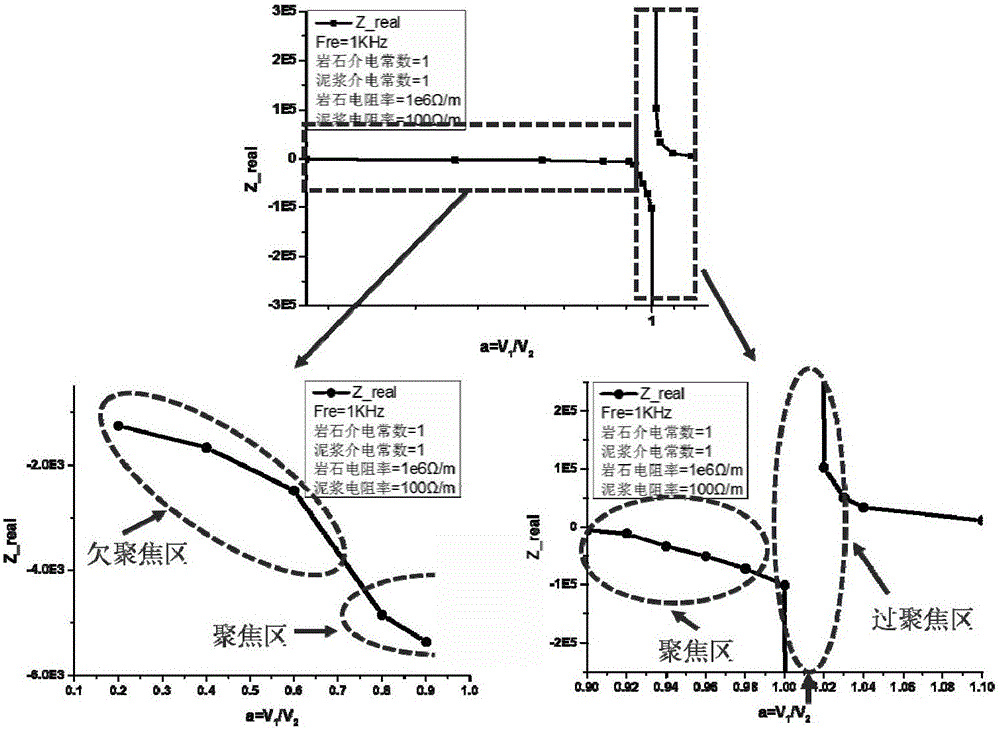

[0012] The present invention adopts specific measures to guide the current to penetrate the conductive mud and enter the inside of the rock, so as to collect and bring out the electrical parameters inside the rock.

[0013] The emitting electrode is set in the ring of the shielding electrode of the ring structure. While supplying power to the emitting electrode, by applying an appropriate voltage to the shielding electrode, the surrounding of the internal electrode is relatively high potential, so that the current flowing from the emitting electrode cannot be pressed along With the conduction of the conductive mud, choosing the appropriate voltage and electrode form can make the current penetrate the conductive mud, enter the interior of the rock, and pass through the rock to reach the grounding plate. The location of the collecting electrodes can be set more flexibly.

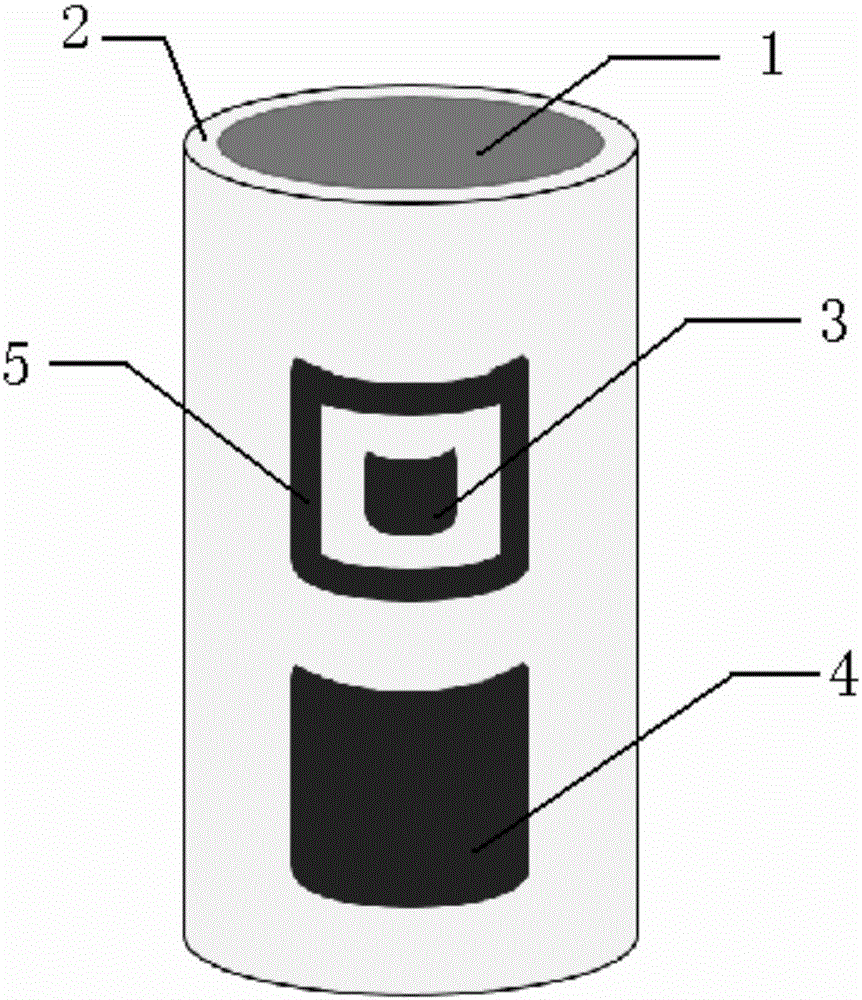

[0014] Such as figure 1 As shown, the rock 1 is wrapped by the conductive mud 2 . The sensor probe includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com