European style range hood for automatically opening and closing oil screen

An automatic opening and closing, range hood technology, applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of polluting the kitchen environment, oil fume backflow polluting the kitchen air, affecting people's health, etc., to block the backflow of oil fume, prevent Effects of Air Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

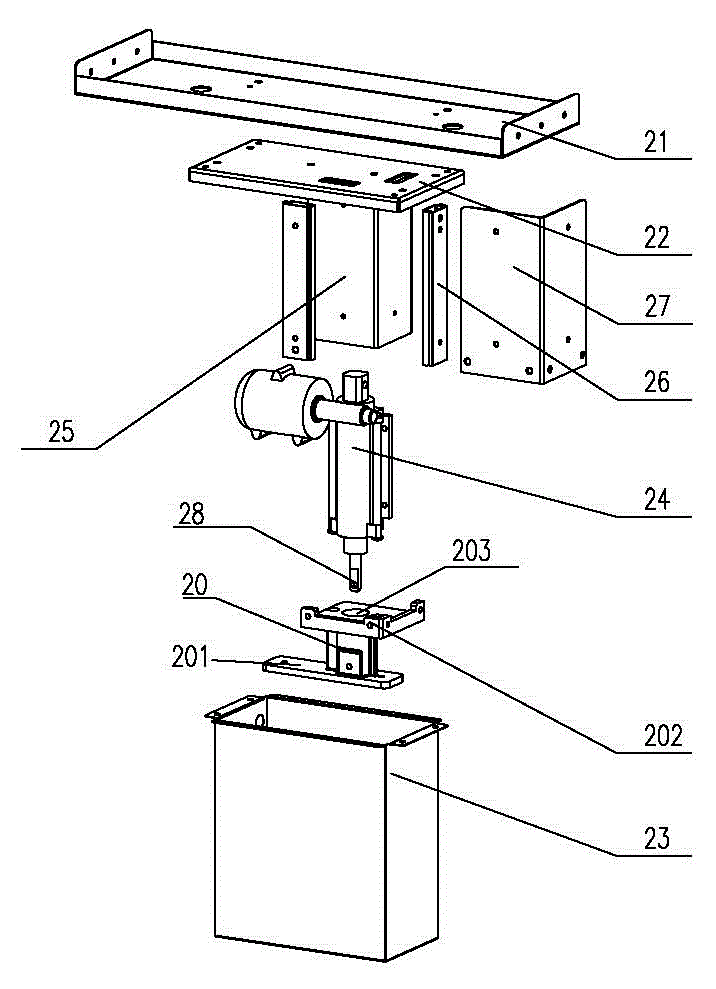

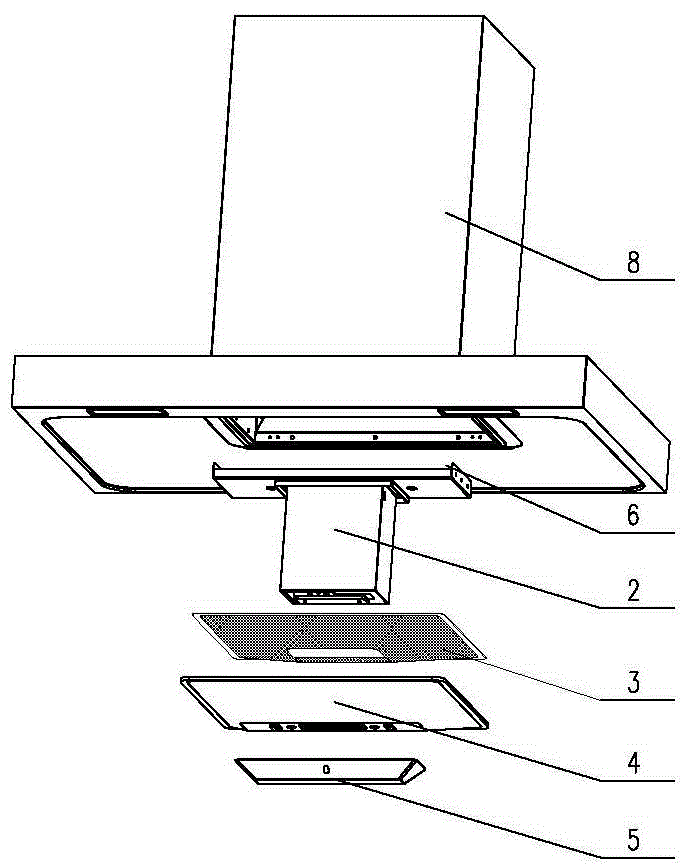

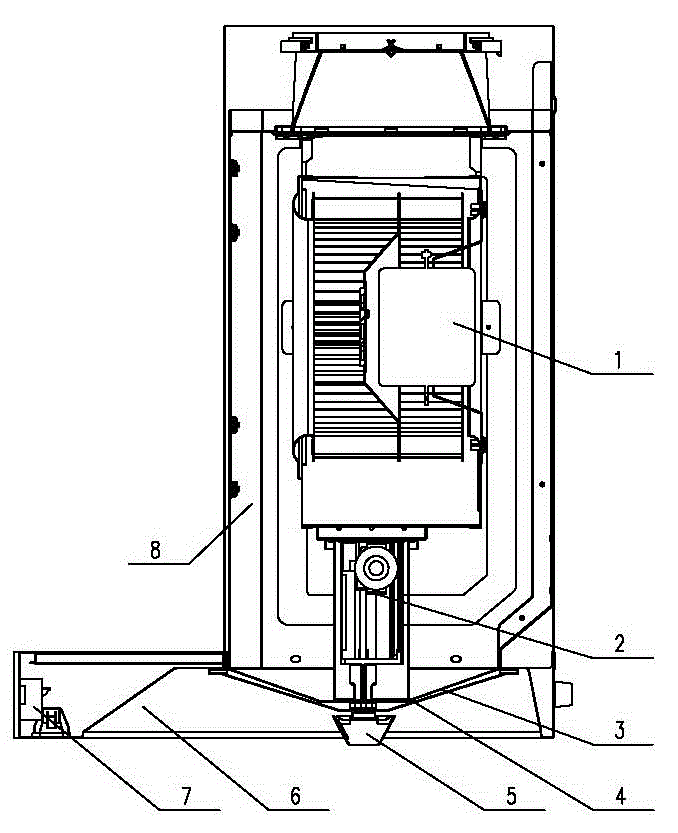

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the embodiment of the present invention proposes a European-style range hood that automatically opens and closes the oil net, including a chassis 8, a transmission mechanism 2 and an oil net 4. The bottom of the chassis 8 is provided with an air inlet 9. The key point is that the transmission mechanism 2 It is accommodated in the protective box 23, including a mechanism fixing plate 21, a bracket 25, a slide rail 26, a push rod motor 24, a connecting plate 27 and a connecting base 20. The mechanism fixing plate 21 is fixed under the fan system 1 inside the chassis 8. The The bracket 25 is a cuboid structure, the upper end is fixed on the reinforcement plate 22, the upper end of the reinforcement plate 22 is fixed on the mechanism fixing plate 21, the push rod motor 24 is fixed on one side of the bracket 25, and the slide rails 26 are set as two, which are respectively fixed on the bracket 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com