A three-axis fine-tuning device for machine tool processing

A three-axis fine-tuning, machine tool technology, applied in the field of machining, can solve the problems of low adjustment accuracy, hinder processing efficiency, and difficult to meet the fine-tuning of workpieces, and achieve the effect of high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

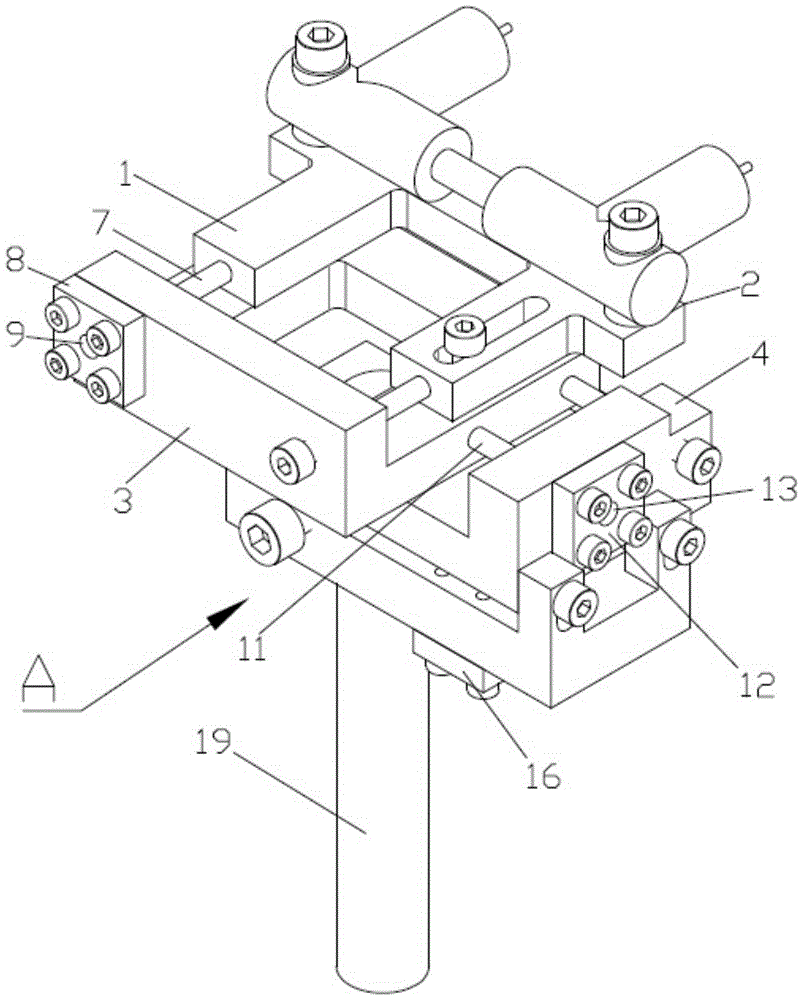

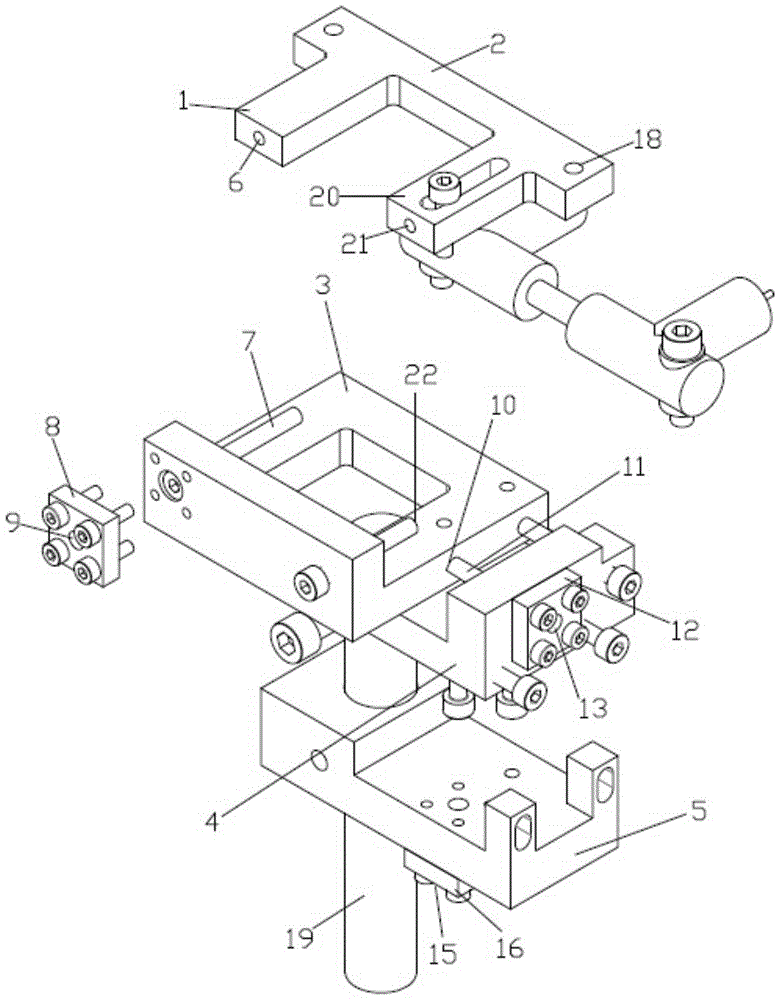

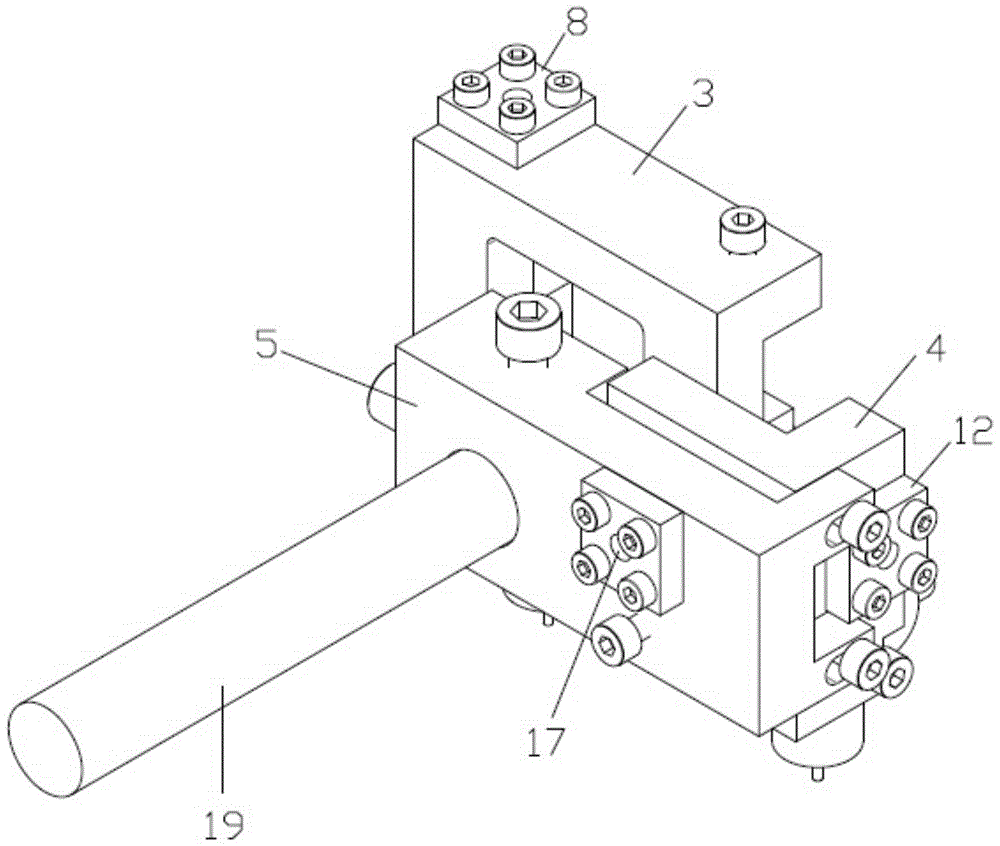

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0024] like Figure 1 to Figure 3 As shown, the application provides a three-axis fine-tuning device for machine tool processing, which is suitable for the machining industry and can optimize the structure of the existing workpiece adjustment device, thereby realizing the function of three-axis adjustment with high adjustment accuracy specialty.

[0025] The above-mentioned three-axis fine-tuning device for machine tool processing includes an X-axis moving base 2 provided with an extension end 1 in the X-axis direction, a Y-axis moving base 3, a Y-axis positioning base 4, and a Z-axis to the positioning base 5;

[0026] The extension end 1 of the X-axis moving base 2 is dug with at least one first hexagon socket threaded hole 6 along the X-axis direction;

[0027] The Y-axis moving base 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com