A device and method for pulling out coiled tubing under pressure

A process method and tubing technology, which is applied in the field of coiled tubing device with pressure pulling out, can solve the problems of reservoir damage, manpower and material resources, etc., and achieve the effect of avoiding injury and high-efficiency pulling out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

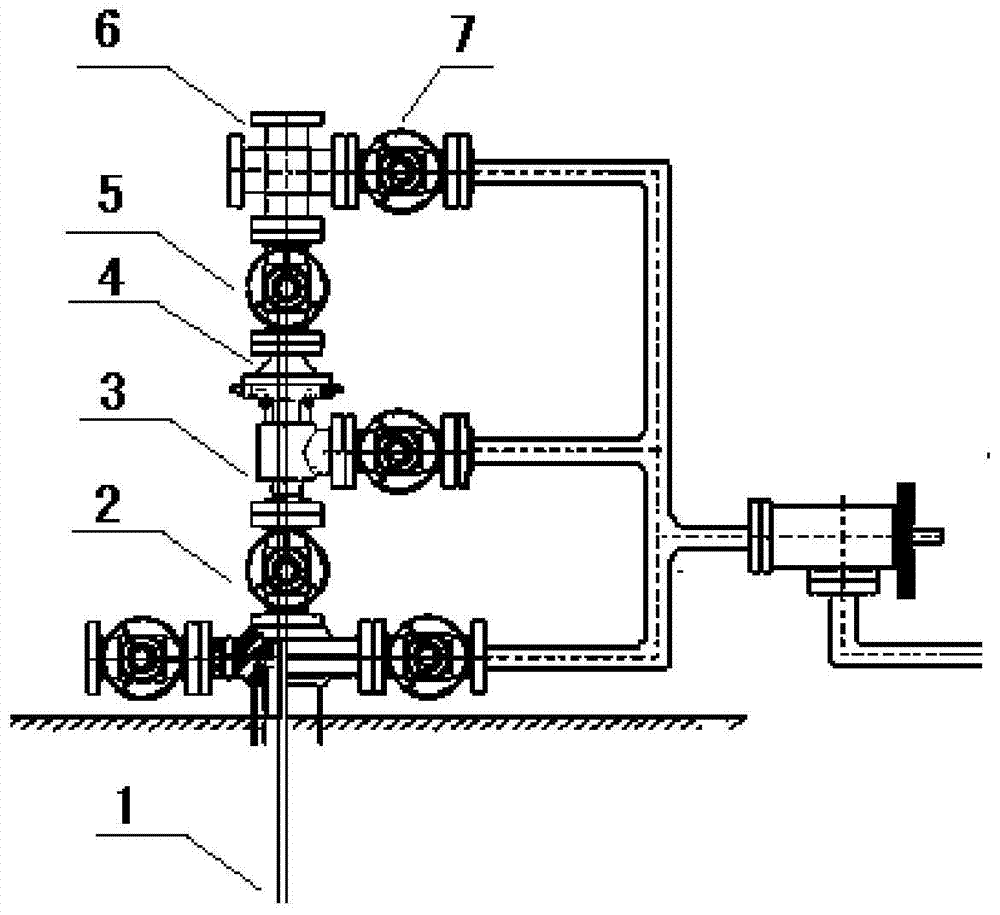

[0032] Embodiment 1: a kind of coiled tubing device with pressure, such as figure 1 As shown, the lower end of the coiled tubing 1 goes down into the wellbore, the upper end of the coiled tubing 1 passes through the main control valve 2 and the first reducing flange 4, and is suspended on the hanger 3, and the main control valve 2 is connected to the hanger 3, The other end of the hanger 3 is connected to the first reducing flange 4, the other end of the first reducing flange 4 is connected to the gate valve 5, the other end of the gate valve 5 is connected to the small cross 6, and the other end of the small cross 6 is connected to the gate valve 7 ,

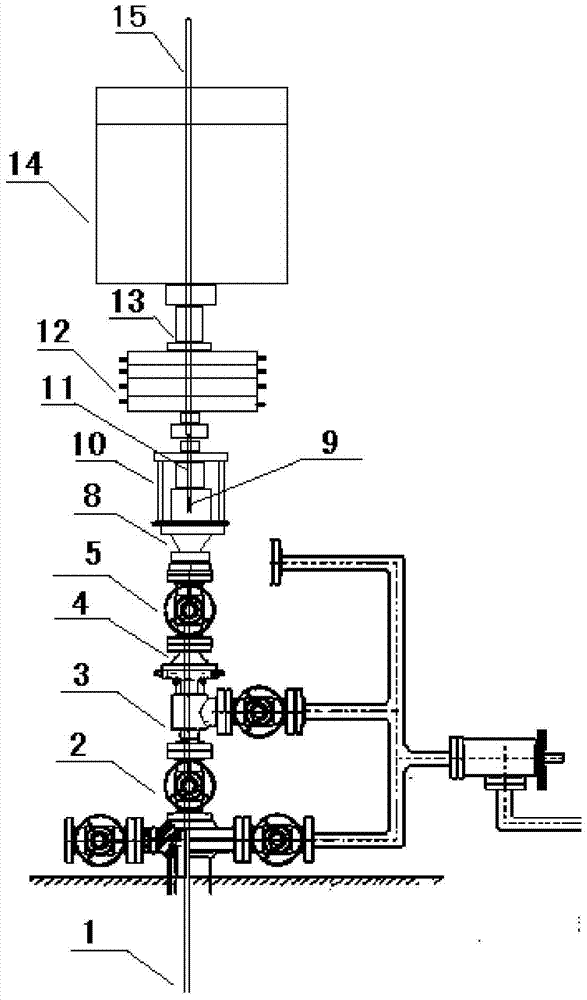

[0033] like figure 2 As shown, the lower end of the coiled tubing 1 goes down into the wellbore, the upper end of the coiled tubing 1 passes through the main control valve 2 and the reducing flange 4, and is suspended on the hanger 3, the main control valve 2 is connected with the hanger 3, and the hanger 3 The other end of ...

Embodiment 2

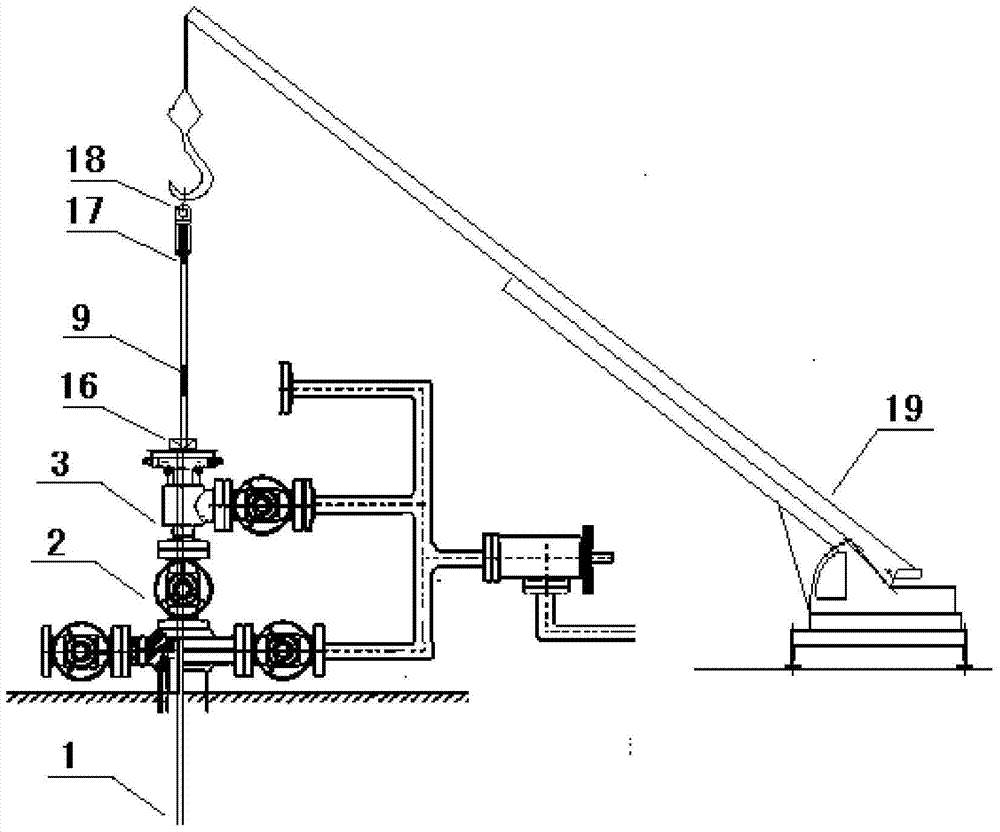

[0036] Embodiment 2: a kind of method that is used for the coiled tubing in the gas well that is pulled out under pressure, such as figure 1 , figure 2 , image 3, Figure 4 as shown,

[0037] 1. Insert the plug in the pipe;

[0038] (1) Close the gate valve 5, and remove the upper gas tree, that is, the small cross 6 and the gate valve 7.

[0039] (2) Using explosion-proof tools, install the second reducing flange 8, the operation window 10, the four-ram BOP 12, the BOP box 13, and the injection head 14 on the upper part of the gas tree gate valve 5 in sequence.

[0040] (3) Connect the first running tool 11 and the second running tool 15 , and then pass them through the injection head 14 , the blowout prevention box 13 , the four-ram blowout preventer 12 , and the operation window 10 . Open the operation window 10, and connect the connected first feeding tool 11 and the second feeding tool 15 with the in-line plug 9 at the inner cylinder thereof.

[0041] (4) Seal the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com