Packer for complicated small pit shaft and setting method thereof

A wellbore and packer technology, which is applied in sealing/isolation, earthwork drilling, wellbore/well components, etc., can solve the problem that the packer cannot meet the requirements of irregular slimhole drilling and isolation, etc. To achieve the effect of simple structure and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

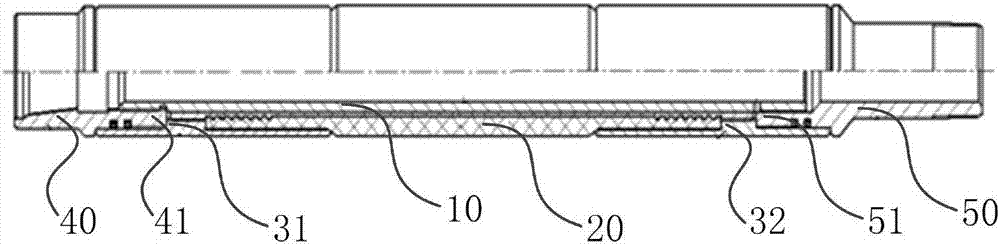

[0020] Such as figure 1 As shown, the present invention provides a packer used in complex small wellbore, including: a center pipe 10, which is provided with a pressure transmission hole, and the pressure transmission hole has a pressure transmission function, which can provide a seal for the expansion of the packer. Hydraulic channel; upper joint 40, whose first end 41 is connected to the first end of the central tube 10; lower joint 50, whose first end 51 is connected to the second end of the central tube; rubber tube 20, sleeved on the central tube 10 , one end is connected to the first end 41 of the upper joint 40 through the upper rubber base 31 , and the other end is connected to the first end 51 of the lower joint 40 through the lower rubber base 32 .

[0021] Wherein, the rubber tube 20 is an expansion type rubber tube with a small diameter and a large sealing coefficient, with vulcanized cores at both ends. When hydraulic pressure is applied to the central pipe 10, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com