A tooling equipment for loading and unloading cabins on the ground for loading and unloading cargo in space capsules

A technology of tooling equipment and space capsule, which is applied in the fields of space navigation ground equipment, space navigation equipment, transportation and packaging, etc., and can solve the problem that spacecraft is not applicable, loading equipment is difficult to load, and it is difficult to ensure the safety and stability of goods Sex and other issues, to achieve the effect of reducing human intervention, low cost, improving work stability and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

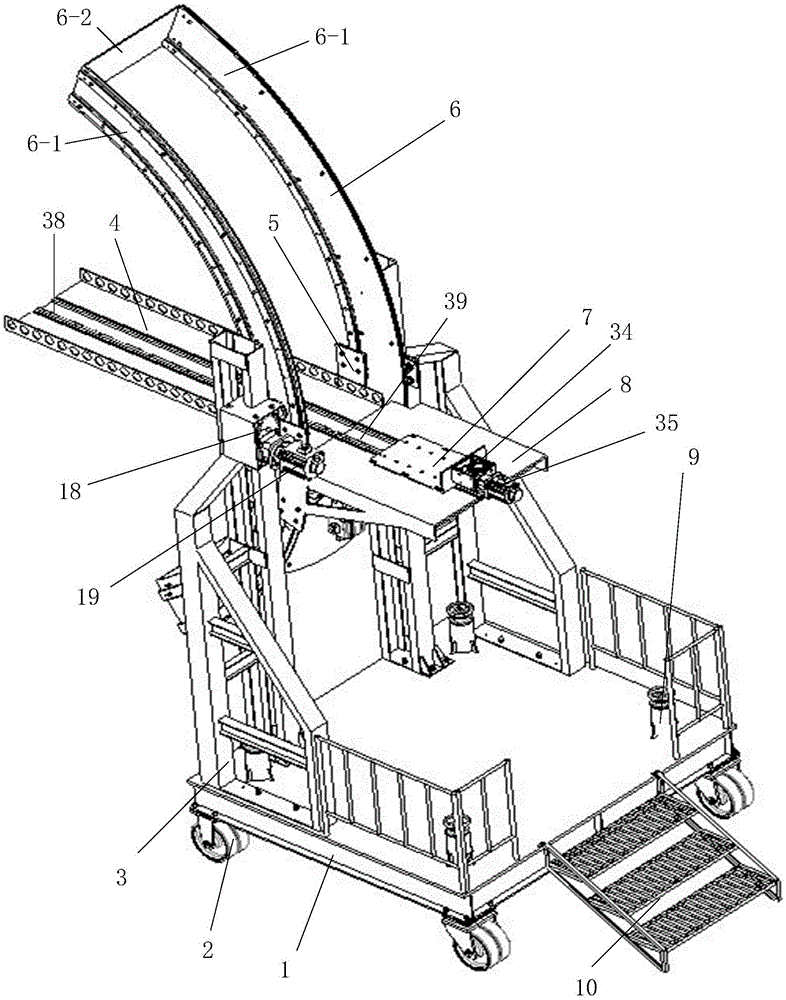

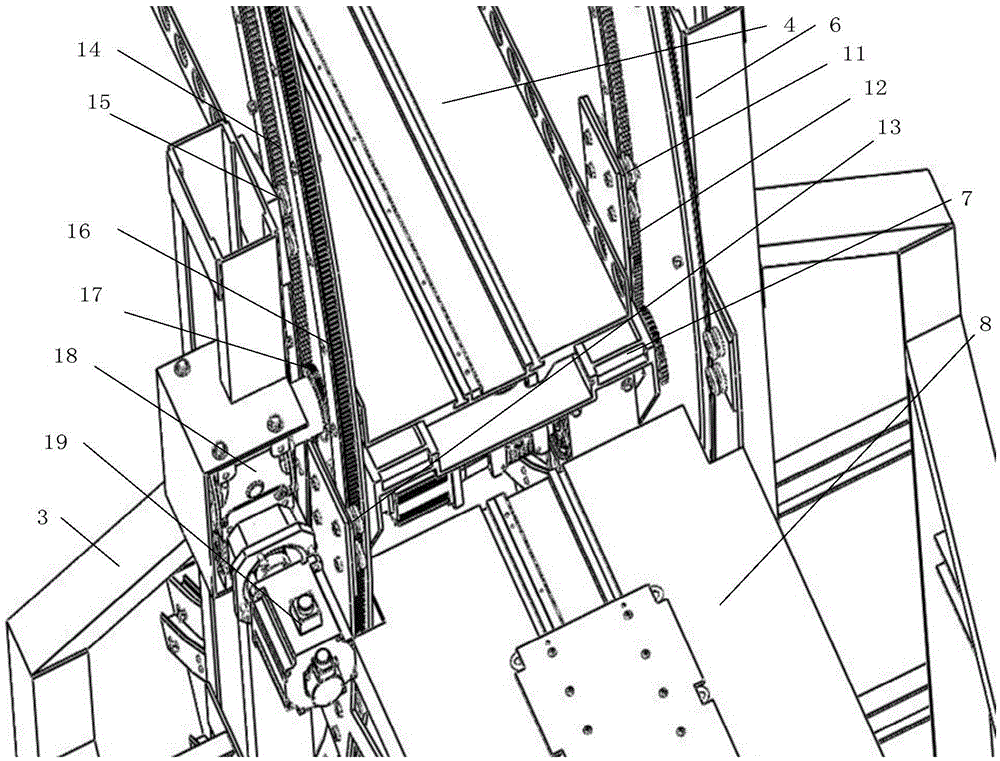

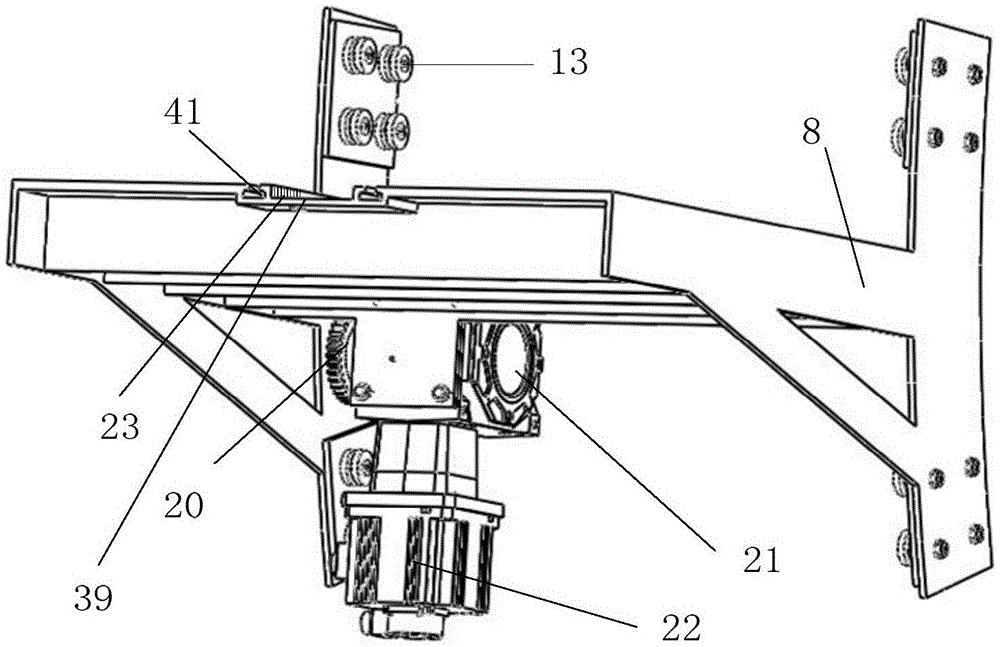

[0020] Such as figure 1 As shown, the bottom of the bracket 1 can realize four casters 2 for its movement. The casters at the front of the bracket are directional wheels, and the casters at the rear are universal wheels. The support cylinder can be supported and fixed on the bracket. 9. Two opposite guide rail frames 3 are also arranged on the bracket, and the guide rail frames are fixed on the upper end surface of the bracket by bolts. The arc-shaped (concentric arc) main rail 6 of the body coaxial line, the main rail is composed of two corresponding arc-shaped rails 6-1 and a connecting plate 6-2 between them, the two arc-shaped rails Respectively close to the inner sides of the two guide rail frames, it is used to fixedly install the rack 14 and the rack 16, and the main rail realizes its movement through the power assembly fixed on the rail frames, such as figure 1 and figure 2 As shown, the power assembly is composed of a motor 19, a reducer 18 and a gear 17, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com