Structure for connecting inner pipe of drill rod and pup joint of drill rod

A technology of connecting structure and short joints, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problems of safety accident, easy tripping, vibration, etc., and achieve the effect of avoiding relative rotation, improving work stability and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

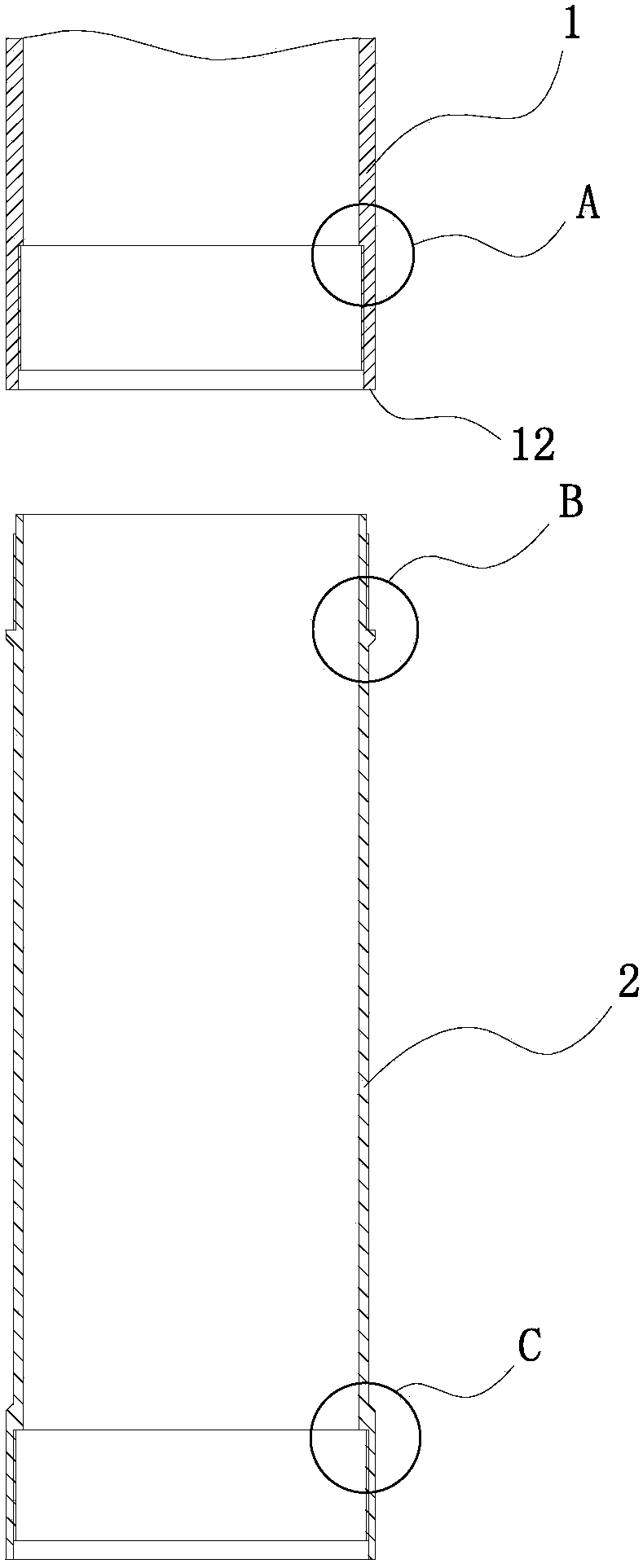

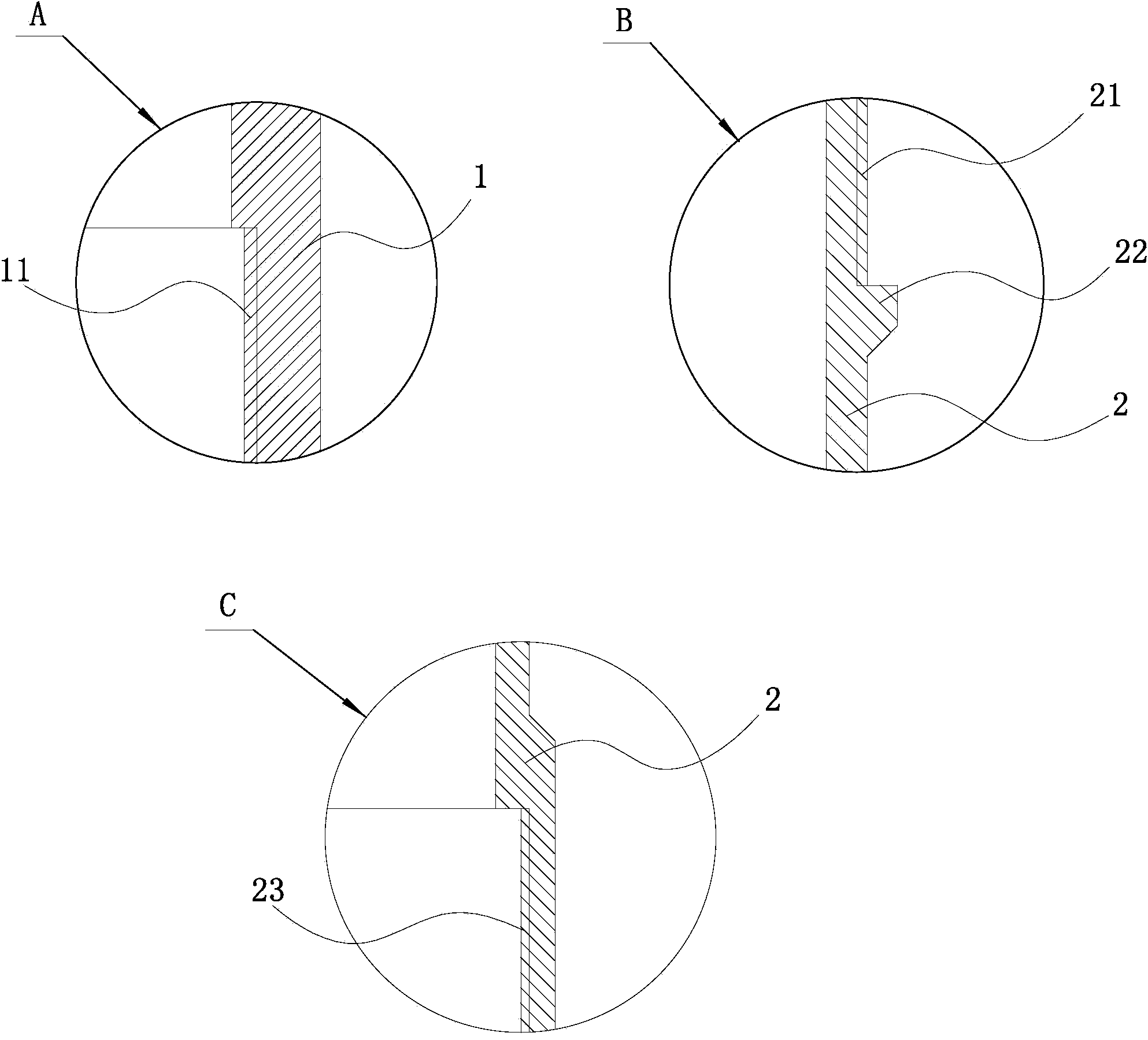

[0011] See figure 1 and figure 2 , the present invention includes an inner pipe 1 with an internal thread 11 at one end and a short joint 2 with an external thread 21 at one end, the inner pipe 1 and the short joint 2 are spirally connected through the internal thread 11 and the external thread 21; the short joint 2 The root of the external thread 21 has a positioning flange 22. When the short joint 2 and the inner pipe 1 are spirally connected, the positioning flange 22 is close to the end 11 of the inner pipe 1 to prevent excessive screwing between the short joint 2 and the inner pipe 1. It is not convenient to separate the two. In the present invention, the other end of the short joint 2 is a connecting portion 23 with an internal thread, and the connecting portion 23 is used for screwing connection with another inner pipe.

[0012]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com