Cloth pressing device of control type cloth press

A cloth pressing device and technology of a cloth pressing device, applied in transportation and packaging, spreading thin soft materials, thin material handling, etc., can solve problems such as unevenness, position deviation from the original position, cloth cutting, and inconvenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below according to the drawings and embodiments.

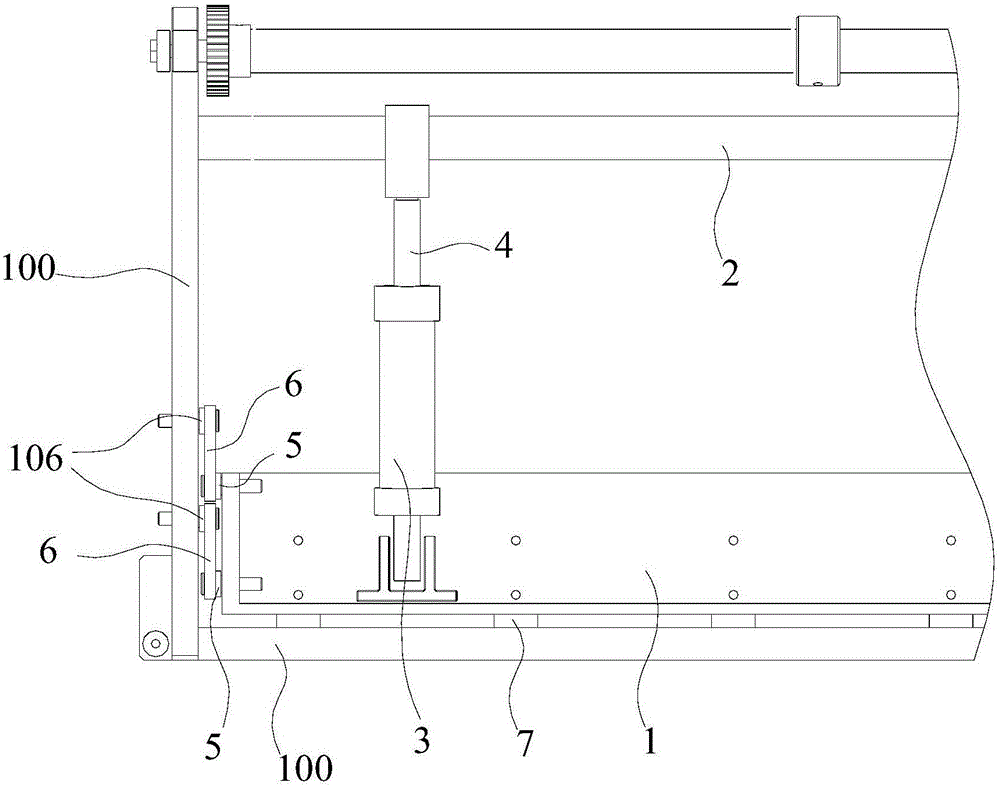

[0014] refer to figure 1 , a cloth pressing device of a controlled cloth press, comprising: a cloth pressing plate 1, a fixed shaft 2, and at least one driving cylinder 3, and the two ends of the fixed shaft 2 are respectively fixed on the inner surfaces of the two above-mentioned frame bodies 100, The two ends of the above-mentioned cloth clamping plate 1 are respectively hinged on the inner surfaces of the two above-mentioned frames 100 and rotate vertically. The above-mentioned driving cylinder 3 is hinged on the above-mentioned cloth pressing plate 1 and rotates vertically. The piston rod of the above-mentioned driving cylinder 3 4. It is hinged on the above-mentioned fixed shaft 2 and rotates vertically. When the above-mentioned driving cylinder 3 is not activated, the bottom surface of the above-mentioned cloth clamping plate 1 is flat and close to the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com