Car for tailoring straight edges of papers

A paper and trolley technology, which is applied in metal processing and other directions, can solve problems such as low work efficiency, uneven wavy edges, and affect the decorative effect, and achieve the effect of improving work efficiency and smoothing and decorative effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

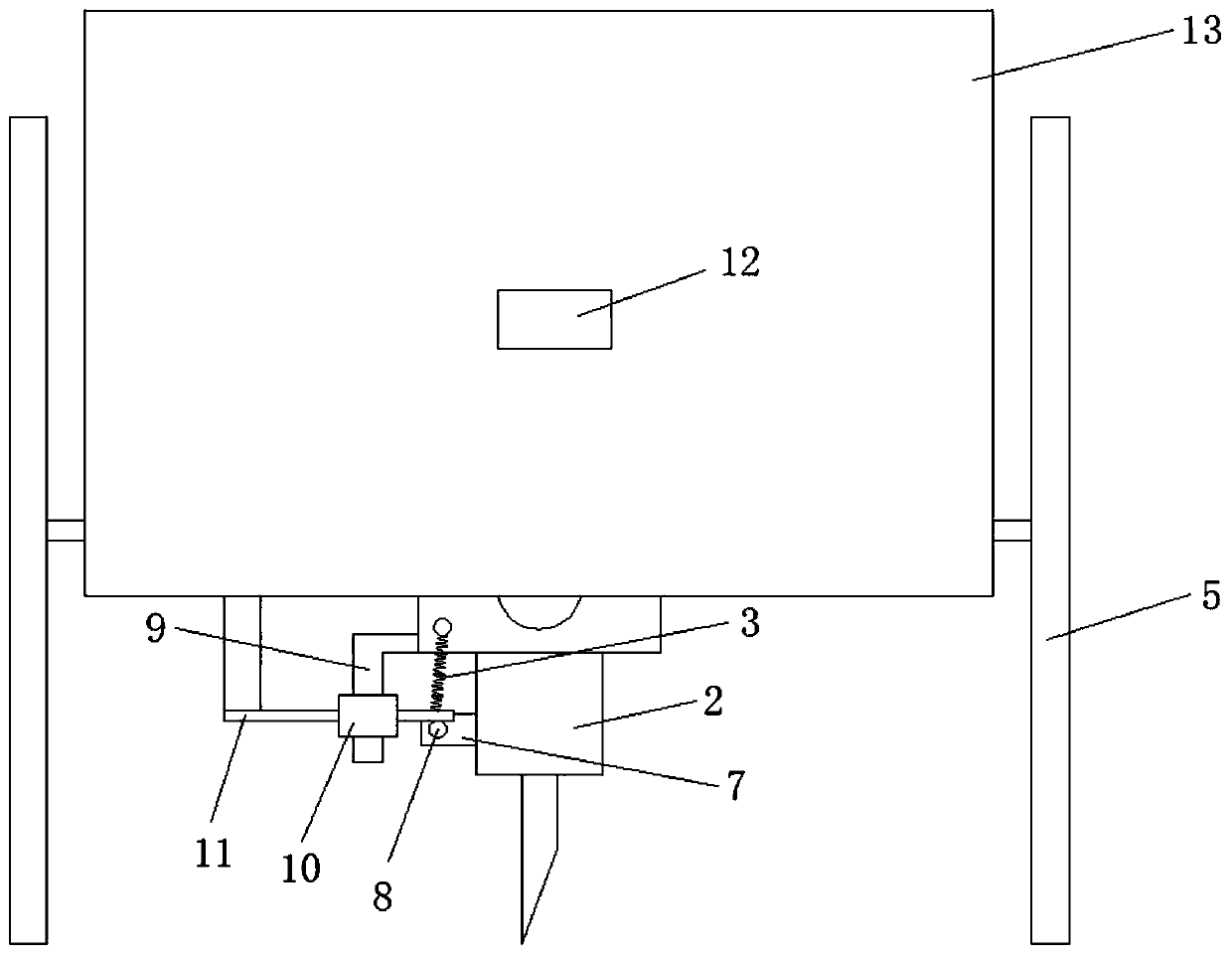

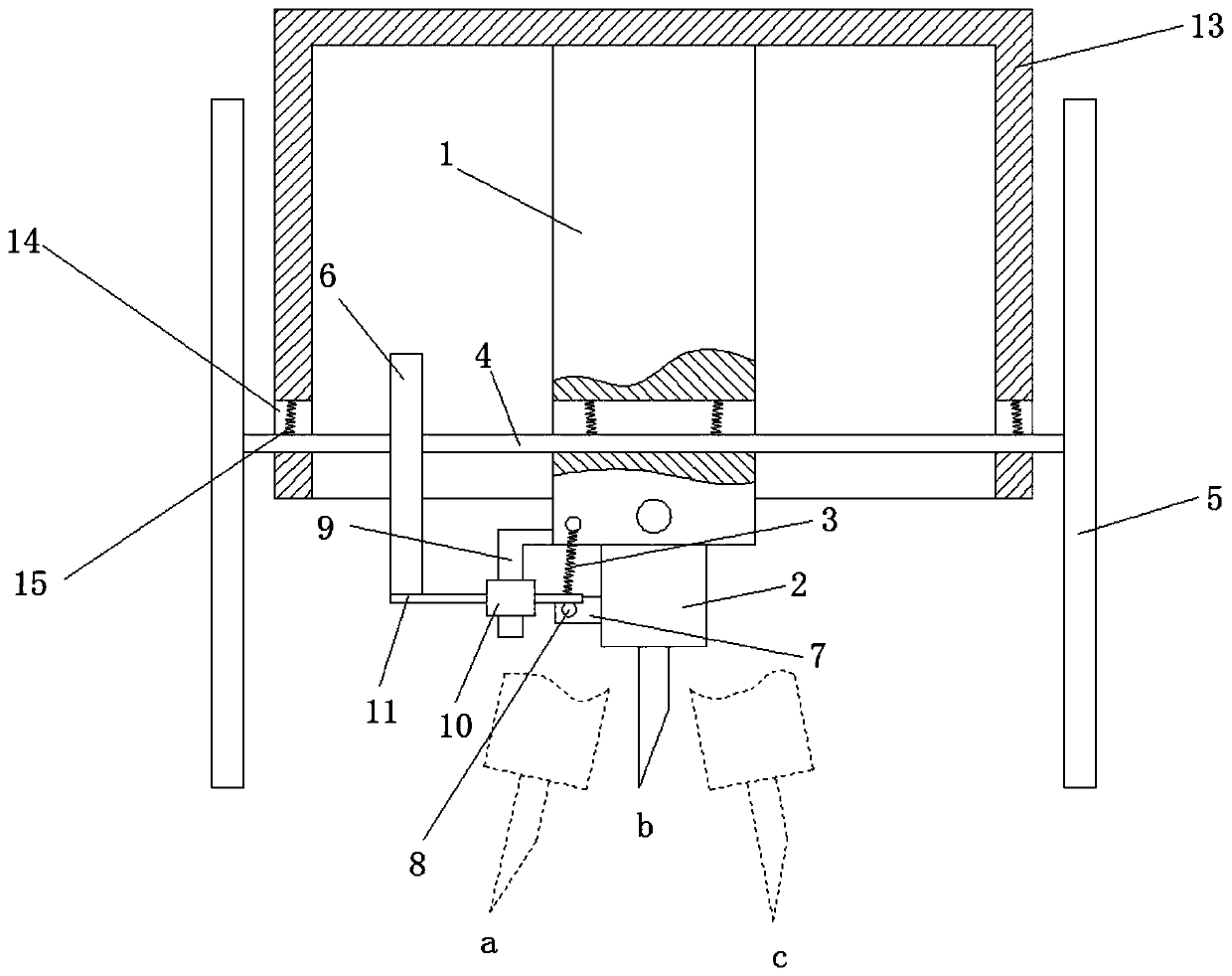

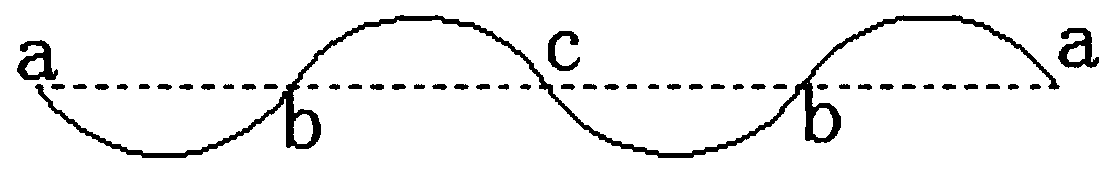

[0024] Such as figure 1 and 2 As shown, a straight-edge dolly for cutting paper includes a car body 13 and a cutter head 2 . The cutter head 2 is hinged on the bottom of the car body 13, and the car body 13 is provided with a device to drive the cutter head 2 to continuously swing toward the both sides of the car body 13 so as to cut the straight edge of the paper into Drive unit with wavy edges. The driving device includes a column 1 , a spring 3 , a rotating shaft 4 , a roller 5 and a cam 6 . The upper end of the column 1 is fixed on the top of the vehicle body 13 , and its lower end extends vertically downwards to the bottom of the vehicle body 1 and then hinges the cutter head 2 . One end of the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com