Method for calculating cavitation performance of large-scale low-lift pump device

A low-lift pump and pump device technology, applied in pump control, non-variable-capacity pumps, machines/engines, etc., can solve problems such as lack of quantitative evaluation indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

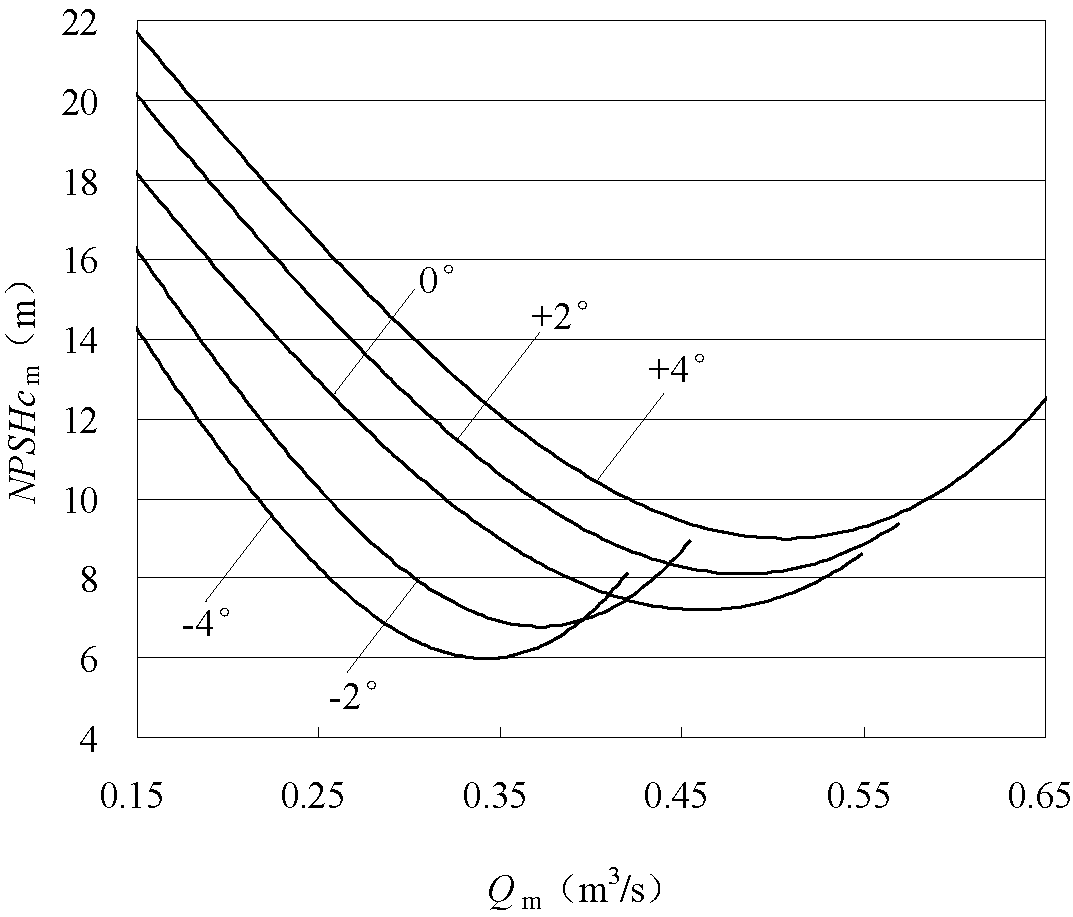

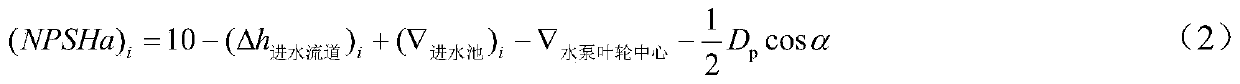

[0090] A large low-lift pumping station adopts an inclined shaft extension pump device, and the angle between the pump shaft and the horizontal plane is α = 15°; the model water pump TJ04-ZL-19 was initially selected in the preliminary design stage, and the impeller diameter of the model water pump is D m =0.3m, the rated speed of the water pump=1450r / min, the impeller diameter D of the prototype water pump of the preliminarily determined pump device p =3.55m, rated speed n p =112r / min, initially set the pump impeller center elevation . The pump impeller of the oblique axial extension pump device of this station has a large diameter, long running time and outstanding importance, and the anti-cavitation safety factor k of the pump device is required 抗空化 ≥[k 抗空化 ] = 1.40.

[0091] This embodiment is to apply the present invention to check whether the anti-cavitation safety factor of the pump device meets the requirements, and the steps are as follows:

[0092] 1. Number th...

Embodiment 2

[0146] A large low-lift pumping station adopts an inclined shaft extension pump device, and the angle between the pump shaft and the horizontal plane is α = 15°; the pump impeller of the inclined shaft extension pump device of this station has a large diameter, long running time and is of great importance. Anti-cavitation safety factor k of the pump device 抗空化 ≥[k 抗空化 ] = 1.40.

[0147] This embodiment is to apply the present invention according to the required pump device anti-cavitation safety factor [k 抗空化 ], select a suitable water pump for the pump device, and determine a reasonable water pump impeller center elevation, the steps are as follows:

[0148] 1. According to the design parameters and operating range of the inclined shaft extension pump device, TJ04-ZL-06, TJ04-ZL- 19 and TJ04-ZL-20 and other 3 model water pumps, they are numbered as l=1, 2, 3 in sequence; the impeller diameters and rated speeds of the 3 model water pumps converted to the corresponding proto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com