a vacuum relay

A technology of vacuum relay and vacuum chamber, which is used in high-voltage air circuit breakers, circuits, electrical switches, etc., to achieve the effect of improving continuous disconnection performance, facilitating the rapid disappearance of arcs, and ensuring vacuum purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

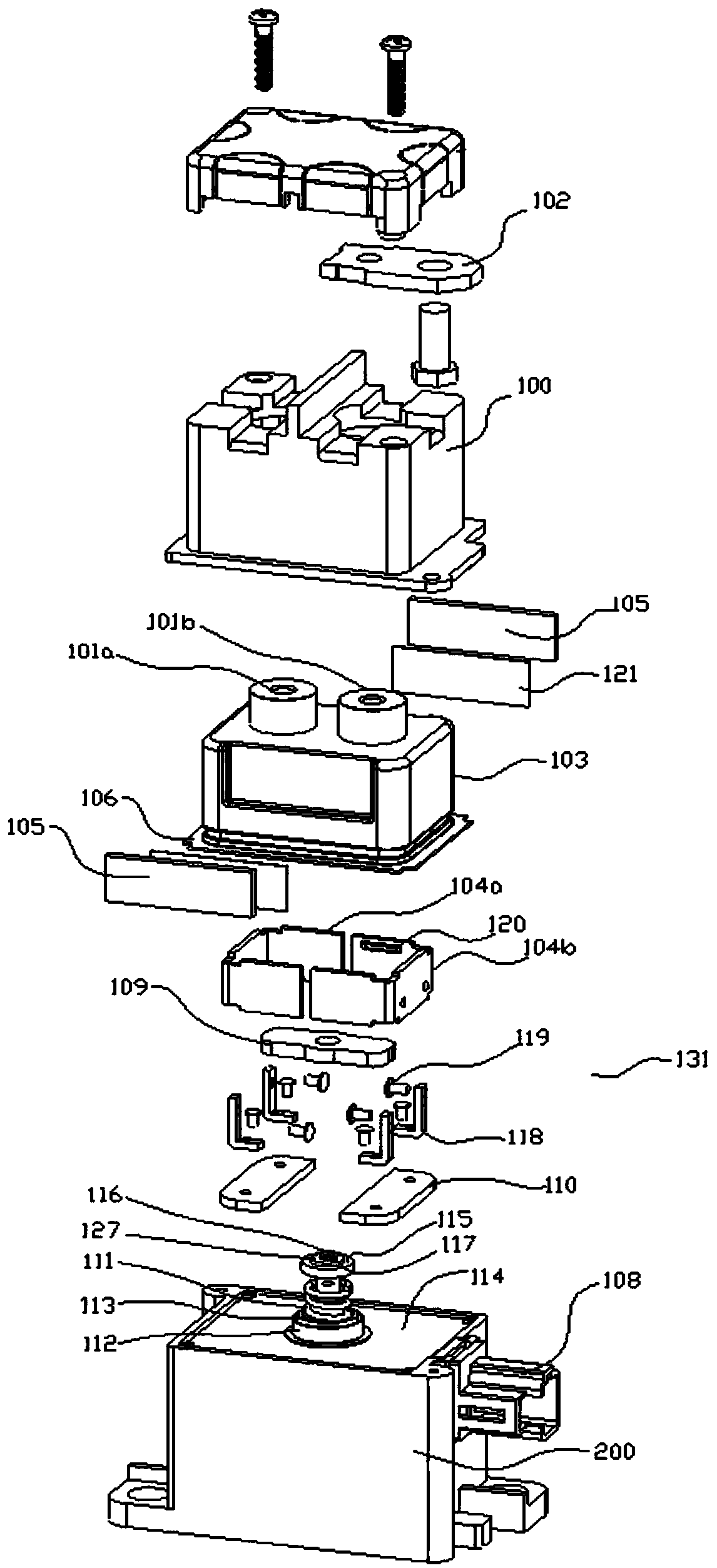

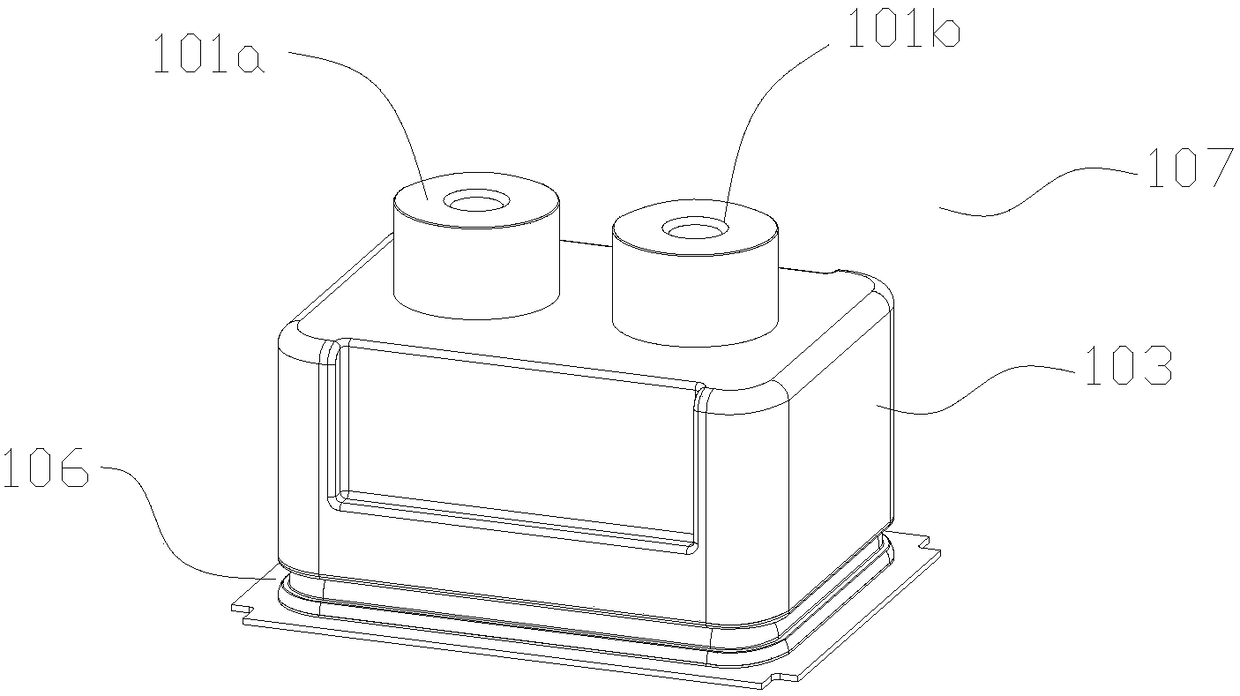

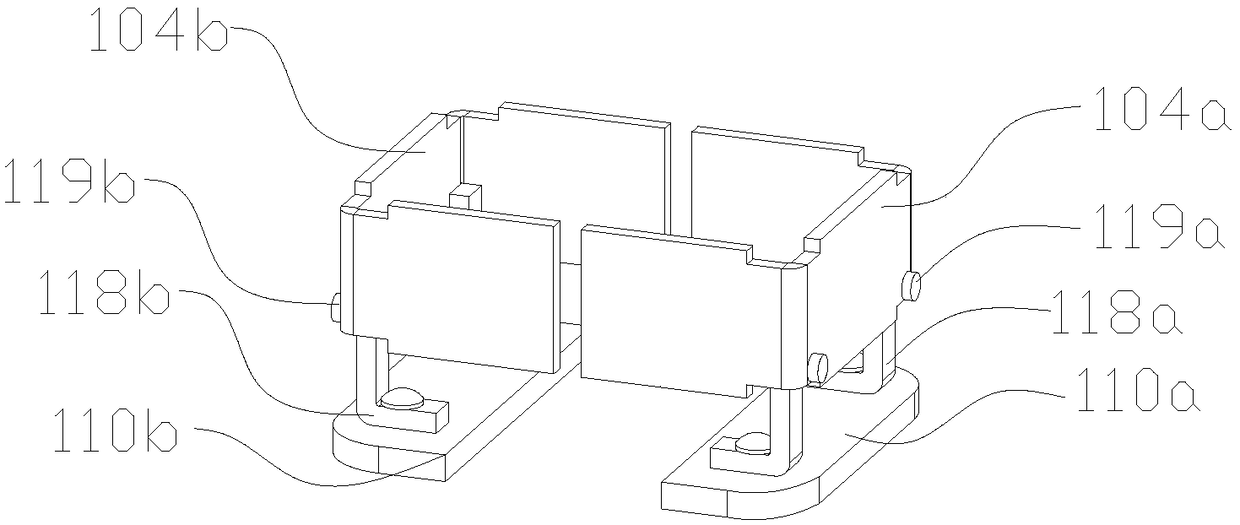

[0035] Figure 1, figure 2 As shown, the vacuum relay provided in this embodiment includes an upper cover 100, static contacts 101a, 101b, a ceramic housing 103, an arc extinguishing mechanism 131, a magnet 105, a base 200, an external connecting insert 108, a moving contact 109, and a base 200 An upper yoke 114 is provided on it. Wherein, the ceramic shell 103 is provided with a connecting member 106, and the upper yoke 114 is provided with a through hole, and the upper yoke around the through hole is fixedly connected with an iron core sleeve 205, and the iron core sleeve 205 is located on the upper yoke 114. Below, the ceramic shell 103 is located above the upper yoke 114 . The ceramic shell 103 and the upper yoke 114 are fixedly connected by the connecting member 106 , so that the ceramic shell 103 , the upper yoke 114 and the core sleeve 205 form a sealed vacuum cavity. The ceramic shell 103 and the upper yoke 114 form a ceramic cavity 107 , and the ceramic cavity 107 i...

Embodiment 2

[0045] Except for the following parts of the vacuum relay provided in this embodiment are different from Embodiment 1, the implementation of the remaining parts is the same as that of Embodiment 1. The details of this embodiment are as follows:

[0046] Such as Figure 6A , 6B As shown, in this embodiment, the arc extinguishing mechanism 130 includes two arc extinguishing grid structures, and each arc extinguishing grid structure includes a set of п-shaped arc extinguishing sheets 123, and these п-shaped arc extinguishing sheets 123 are supported by metal materials . It is connected and fixed by connecting pieces to form an arc extinguishing grid structure. Wherein, the connecting piece is made of insulating metal material. Specifically, the connecting piece includes a connecting fixing rod 124, a washer 125 and a fixing nut 126, all of which are made of insulating processed metal materials. The connecting and fixing rods 124 sequentially pass through the connecting holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com