Automatic control equipment for grain collection and dedusting

A technology for grain collection and equipment, applied in the field of automatic control equipment for grain collection and dedusting, which can solve the problems of environmental pollution, dust and impurities falling, etc., and achieve the effect of overcoming the difficulty of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

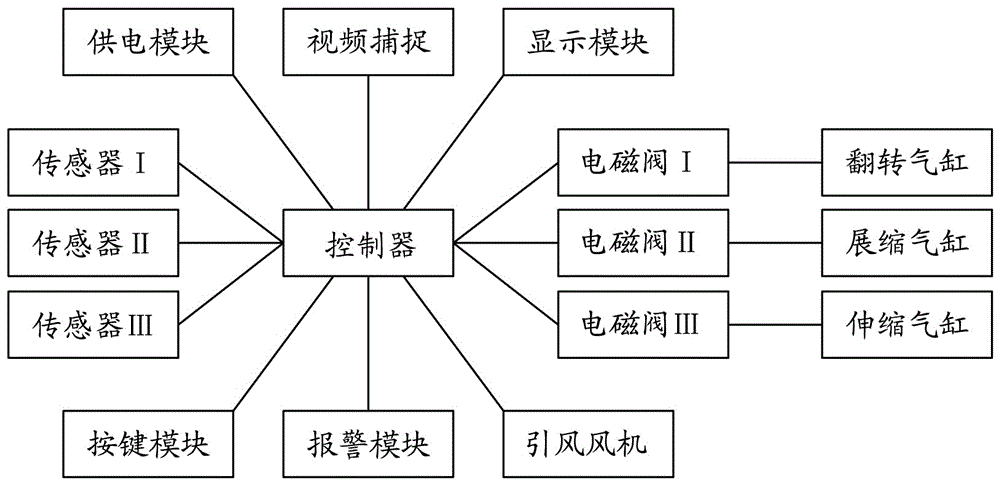

[0013] Automatic control equipment for grain collection and dedusting, including mechanical parts and control parts.

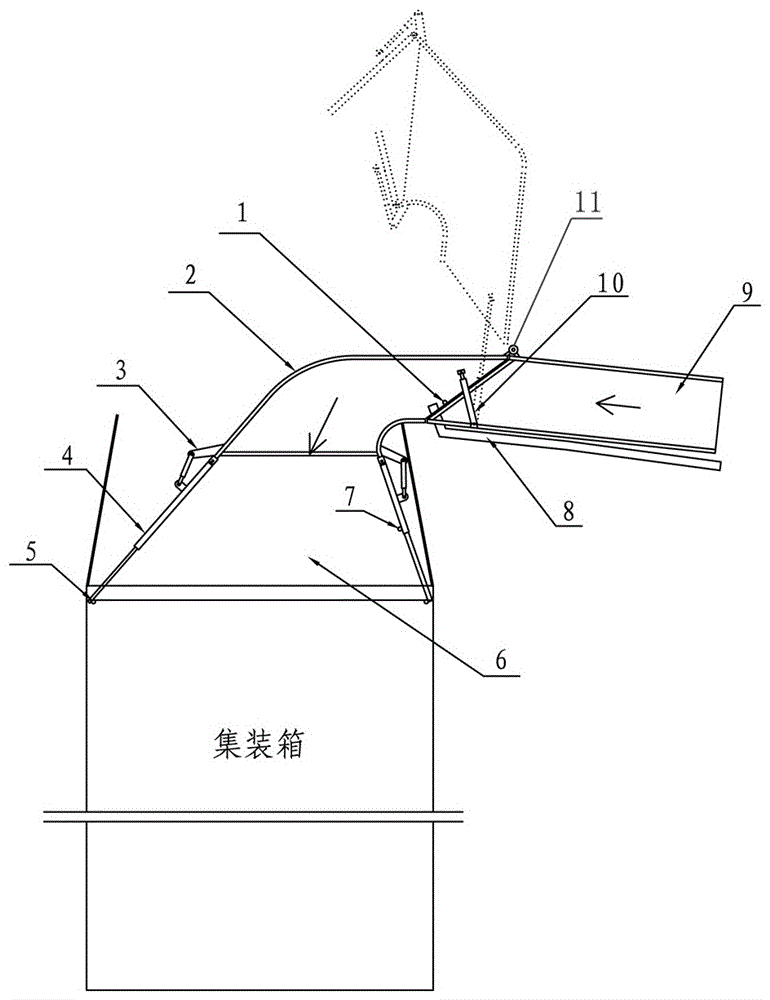

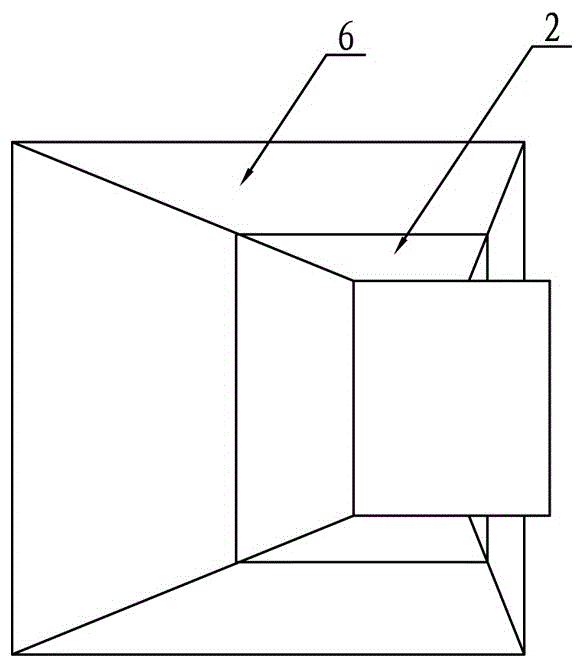

[0014] Such as figure 1 and figure 2 As shown, in the mechanical part, a square tube type dust removal cover 2 with both ends open is made of steel plate, the middle section of the square tube type dust removal cover 2 is in a bent state, and the opening at the top is wedge-shaped And through the rotating shaft 11 is connected with the grain transportation channel, the opening located at the bottom is facing directly below and four telescopic cylinders 4 are installed at the opening, and the four telescopic cylinders 4 are all obliquely extending downwards and extending in the same direction as the container Corresponding to the four vertical edges in the interior, between the square tube type dust removal cover 2 and each telescopic cylinder 4, there are also telescopic cylinders 3 for controlling the expansion and condensation of the telescopic cylinder 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com