Double-layer dish tooth surface combination gasket

A technology of combining washers and washers, applied in washers, connecting components, mechanical equipment, etc., can solve problems such as lack of elasticity and inability to compensate for the loss of preloading force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

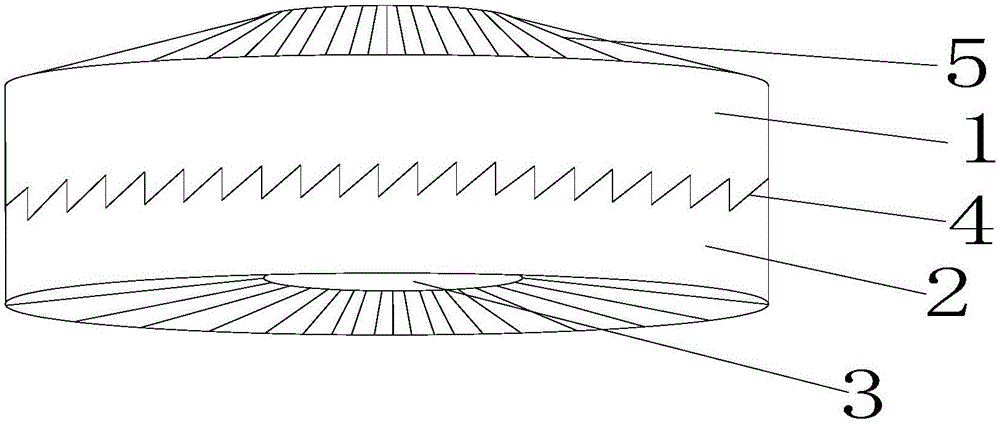

[0016] Such as figure 1 A double-layer dish-shaped tooth surface combined washer is shown, including a first washer 1 and a second washer 2, the first washer 1 and the second washer 2 are provided with through holes 3 inside, the first washer 1 and the second washer 2 The second washer 2 is a disc-shaped structure, the lower surface of the first washer 1 and the upper surface of the second washer 2 are respectively provided with interlocking serrations 4 that interlock with each other, and the first washer 1 and the second washer 2 are engaged by the engaging serrations 4 together. The meshing serrations 4 are preferably radial. The upper surface of the first washer 1 and the lower surface of the second washer 2 are respectively provided with anti-loosening serrations 5 . The anti-loosening saw teeth 5 are preferably radial. The tooth pitch of the meshing sawtooth 4 is greater than the tooth pitch of the anti-loosening sawtooth 5 .

[0017] When the bolt is installed, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com