Nickel-titanium alloy self-sealing bolt

A nickel-titanium alloy, self-sealing technology, applied in the directions of bolts, screws, nuts, etc., can solve the problem of insufficient bolt pre-tightening force, and achieve the effects of convenient and fast heating, easy installation and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

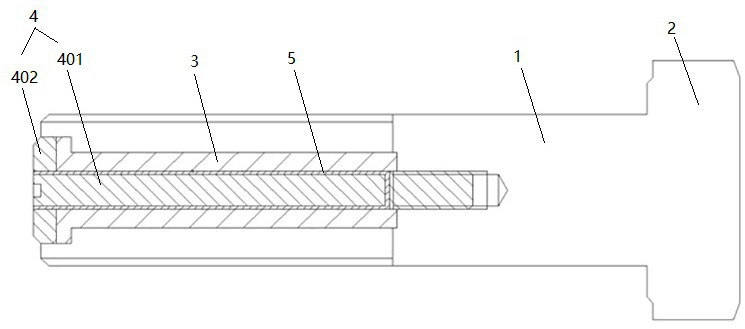

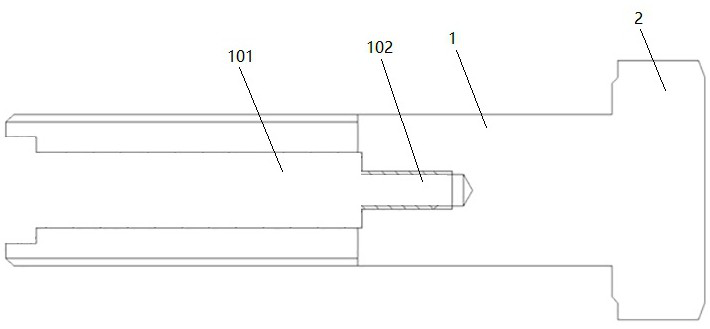

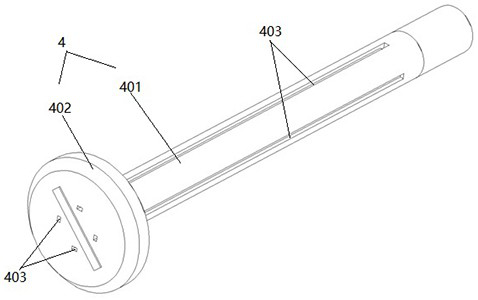

[0020] Please combine Figure 1 to Figure 4 As shown, a nickel-titanium alloy self-sealing bolt involved in the embodiment of the present invention includes a stud 1 and a nut 2, the nut 2 is connected to the head end of the stud 1, the nut 2 can be a standard hexagonal structure, or It can be set to other structures such as slots or cross slots. A stepped hole 101 is provided at the tail end of the stud 1 , and a threaded connection hole 102 is provided at the bottom of the stepped hole 101 . The T-shaped nickel-titanium alloy sleeve 3 is made by axial pre-stretching, and has a size structure matching the stepped hole 101 . The axial distance of the larger diameter tail end 301 of the T-shaped nickel-titanium alloy sleeve 3 is smaller than the axial distance of the large-diameter section of the stepped hole 101, so that the T-sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com