Drill chuck capable of increasing loosening torque

A drill chuck, loosening technology, applied in the direction of the chuck, etc., can solve the problem of exiting from the self-locking state, and achieve the effect of reasonable structure, simple production, and increased loosening torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

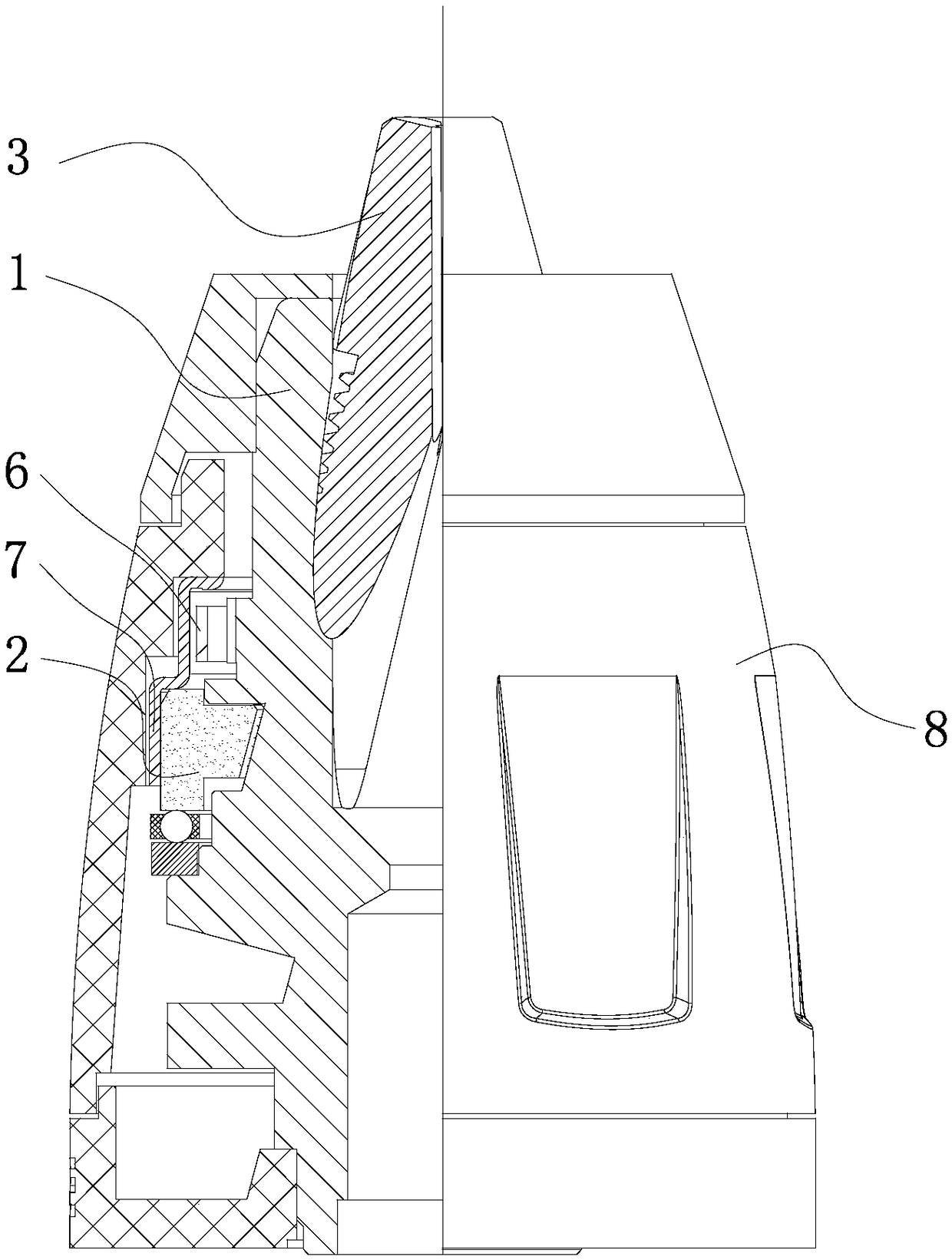

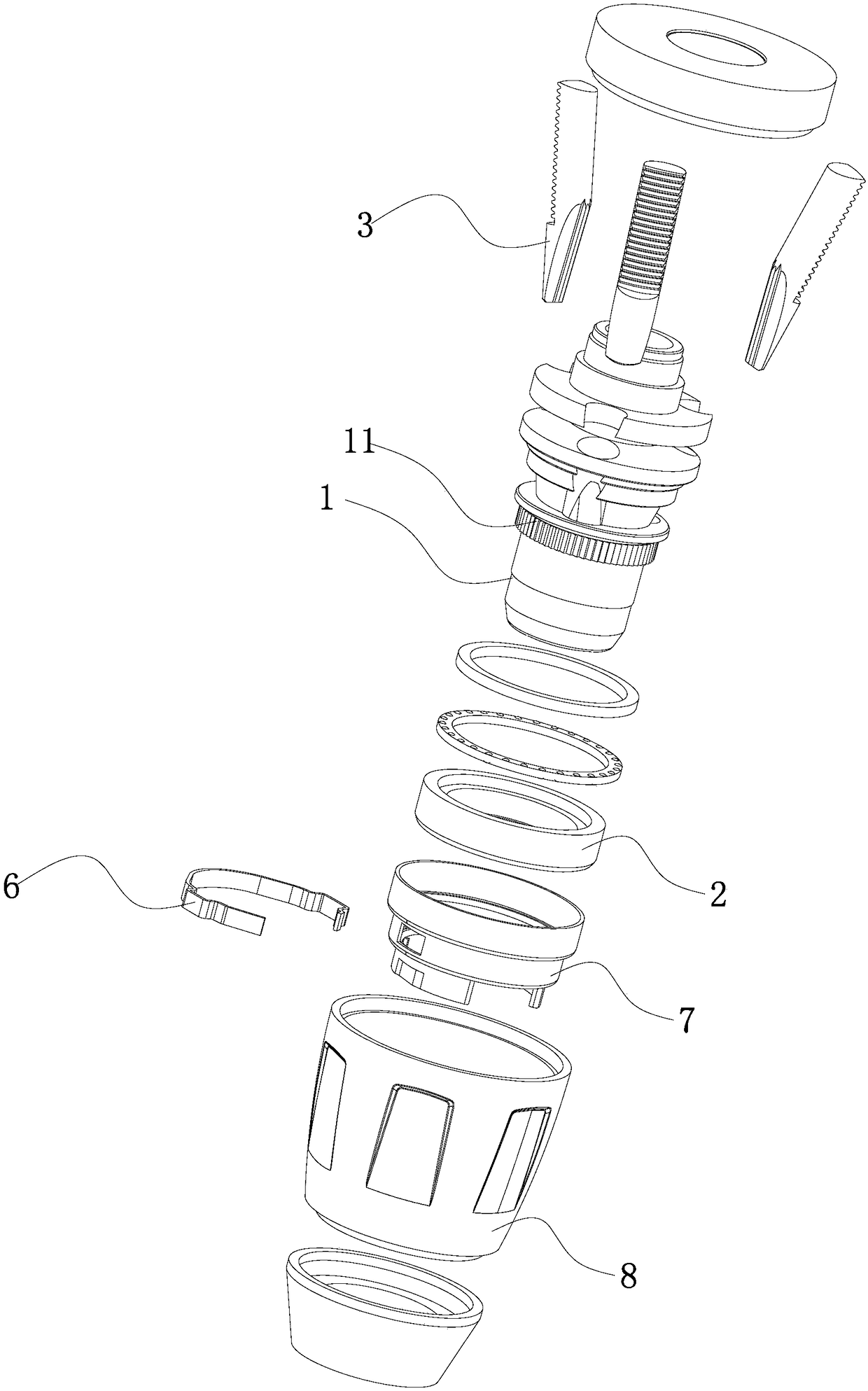

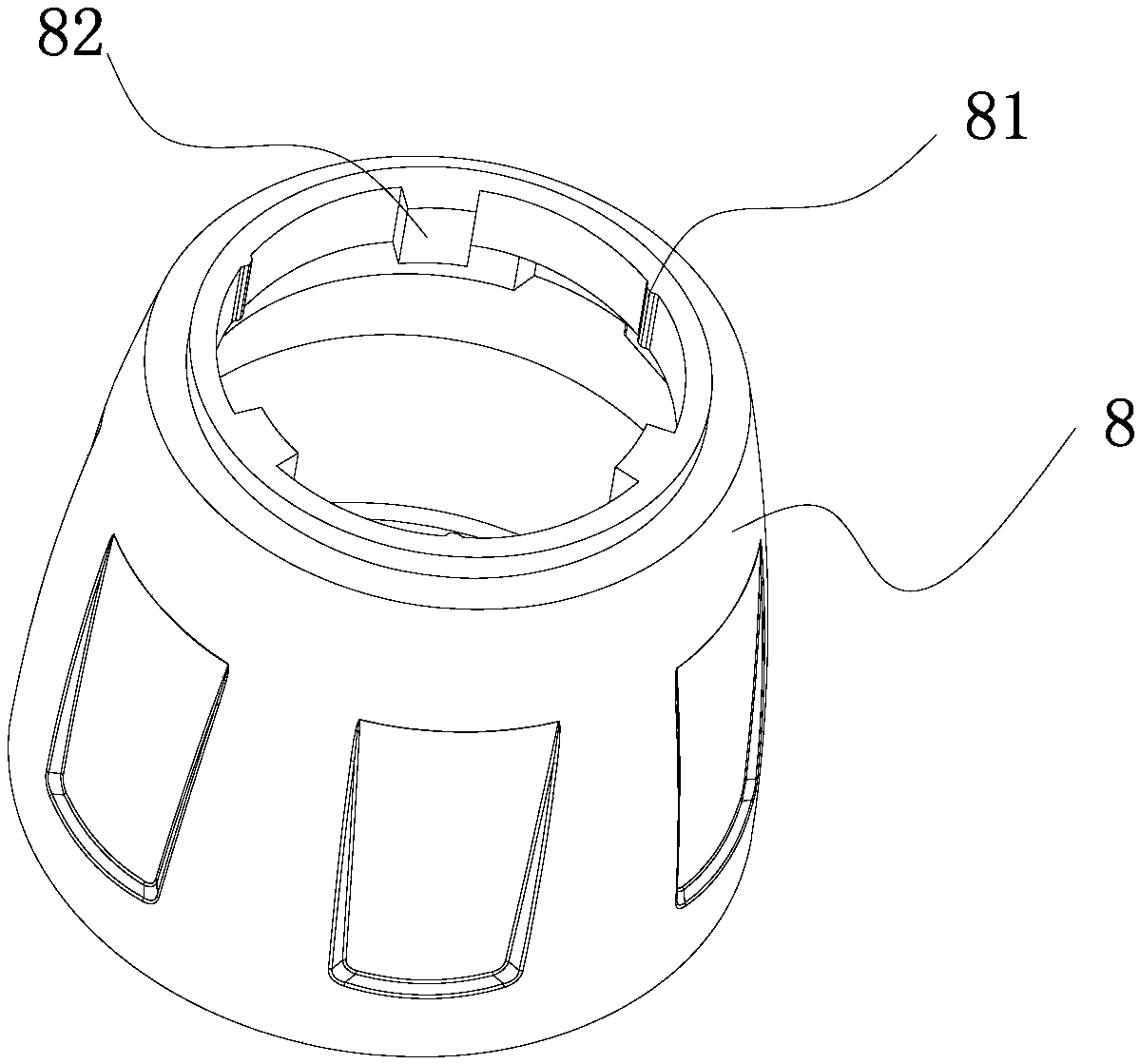

[0020] Refer to attached picture. The drill chuck with increased loosening torque provided by the present invention includes a rotating sleeve 8, a drill body 1, a nut 2, a nut sleeve 7, jaws 3, and a self-locking structure, and the self-locking structure includes teeth 11 and spring plates 6 , the tooth 11 is on the drill body 1, the spring leaf 6 has a locking end 61 that matches the tooth, and the rotating sleeve 8 has a part 84 that is connected to the spring leaf 6 in the self-locking state and is not self-locking. The position 83 connected with the spring leaf, the two sides of the spring leaf 6 have lock end protrusions 62 and positioning protrusions 63 respectively, and the lock end protrusions 62 and positioning protrusions 63 are respectively stuck on the two sides of the nut sleeve. On the first mounting hole 72, a cam surface 85 for the lock end protrusion 62 is also provided in the rotating sleeve.

[0021] The drill chuck is also provided with a self-locking and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com