Long stroke rear balance pulley pumping unit

A long-stroke, pumping unit technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of shortening the service life of wire rope, low efficiency, and low reliability of the reversing mechanism of the tower pumping unit, etc. problem, to achieve the effect of increasing the stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

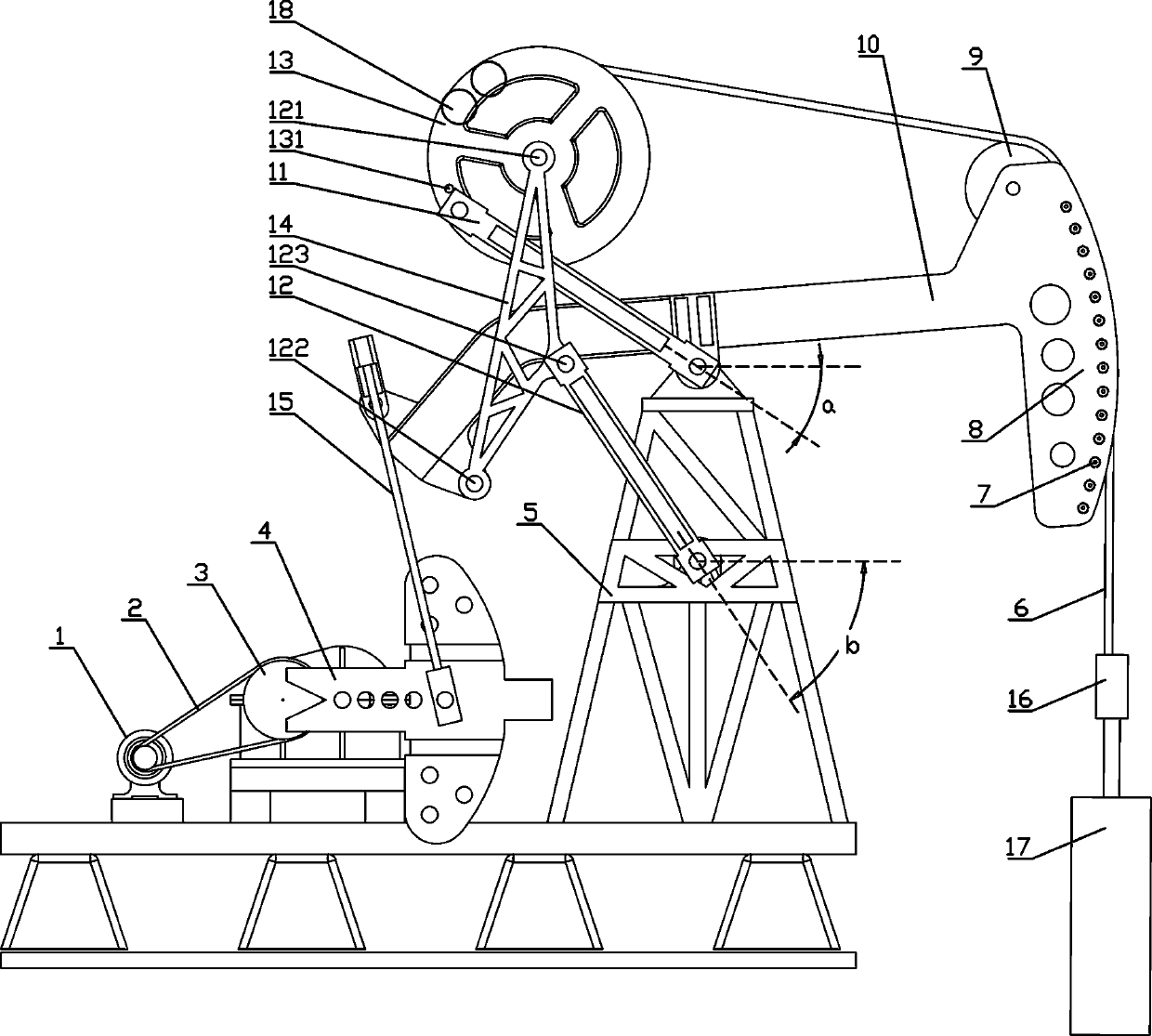

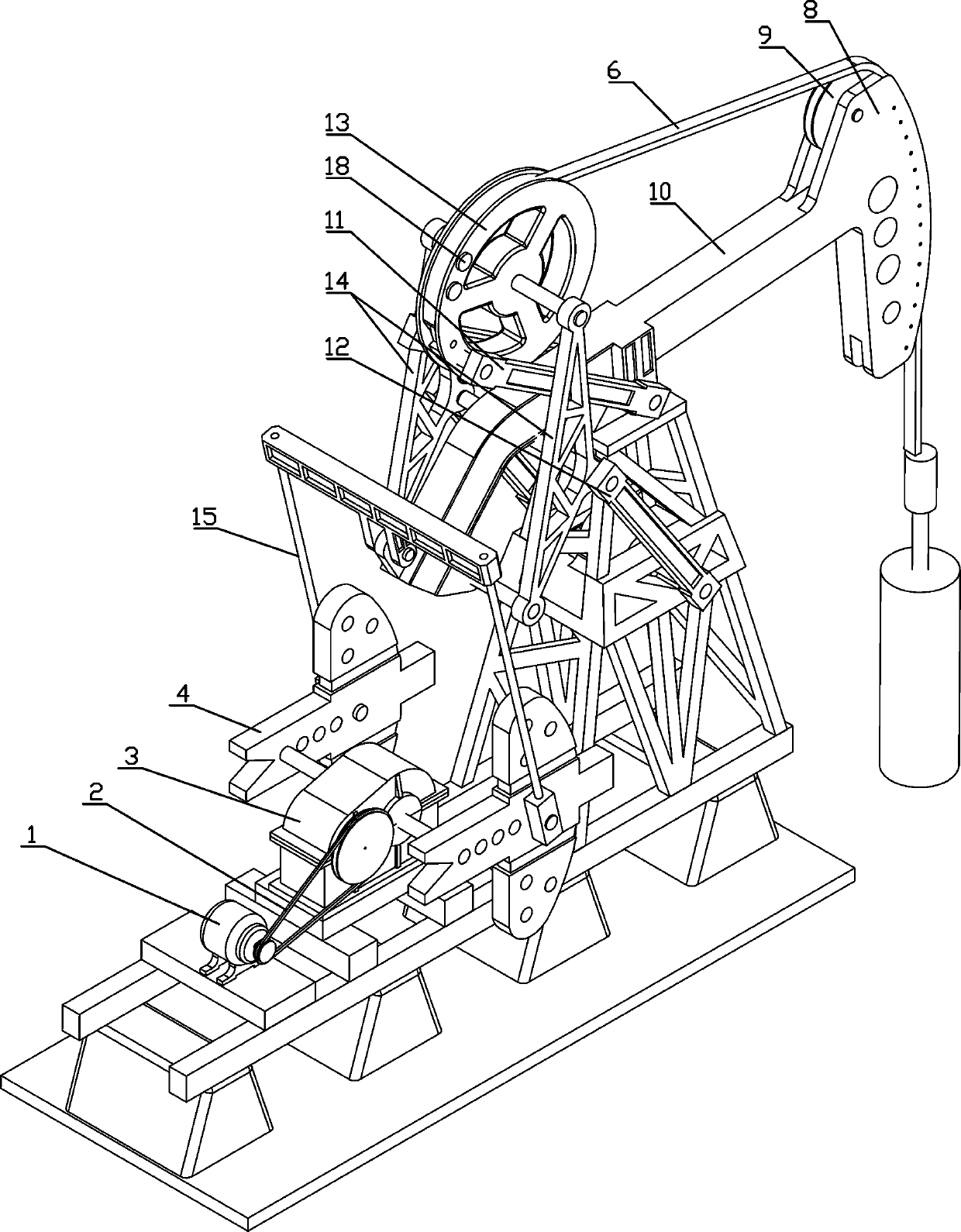

[0025] like figure 1 , 2 Among them, a long-stroke post-balanced pulley pumping unit, including a tower 5, the middle part of the beam 10 is connected to the tower 5 through a bearing, a donkey head 8 is provided at one end of the beam 10, and the other end of the beam 10 is connected to the connecting rod One end of 15 is hinged, and the other end of connecting rod 15 is hinged with the crank 4 driven to rotate by the driving device, specifically: the motor 1 is connected with the input of the reducer 3 through the belt 2, and the output of the reducer 3 is connected with the crank 4.

[0026] One end of the beam 10 close to the connecting rod 15 is hinged with the lower apex 123 of the triangular pendulum 14 , the upper apex of the triangular pendulum 14 is pivotally connected with the shaft of the balance wheel 13 , and the side apex 122 of the triangular pendulum 14 passes through the rocker 12 Connect with the tower 5;

[0027] The position near the edge of the balance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com