Two-channel injection multi-stage packer staged fracturing string and its application method

A staged fracturing and packer technology, applied in the field of fracturing strings, can solve problems such as limited liquid displacement, increased tubing inner diameter, restrictions, etc., to achieve reliable maintenance, improved reliability, and good economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

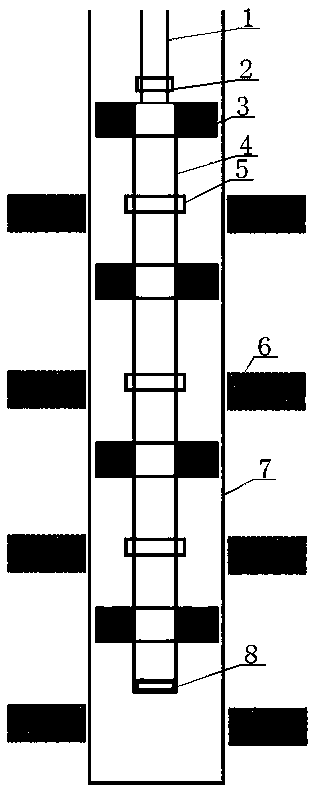

[0021] see figure 1 As shown, the present invention includes an upper oil pipe 1 and a lower oil pipe 4 . Wherein, the diameter of the lower oil pipe 4 is larger than that of the upper oil pipe 1, and the bottom of the lower oil pipe 4 is provided with a bottom ball seat 8; on the lower oil pipe 4, there are multiple sets of packs for forming multi-stage layered fracturing in the axial direction. 3 (four in this embodiment) and fracturing sleeves 5 (three in this embodiment), it can be seen from the embodiment that the packers 3 and fracturing sleeves 5 on the lower tubing 4 form a One pair of corresponding matching methods is arranged alternately, and the extra packer 3 is used as the top packer of the lower tubing 4, and is located at the top of the lower tubing 4. Usually, the area between adjacent packers 3 corresponds to the formation On the reservoir section 6 , the fracturing sliding sleeve 5 between adjacent packers 3 faces the reservoir section 6 . The lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com