Underground thermal fluid generation method and device based on multi-channel continuous pipe

A technology for generating equipment and multiple thermal fluids, which is applied in the fields of mining fluids, geothermal energy power generation, earthwork drilling and mining, etc., can solve the problems of reduced thermal energy utilization rate, increased heat loss of steam injection, large energy loss, etc., to reduce heat loss, The effect of reducing energy consumption and improving the utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the purpose, structure and function of the present invention, a method and device for generating downhole thermal fluid based on multi-channel coiled tubing of the present invention will be described in further detail below with reference to the accompanying drawings.

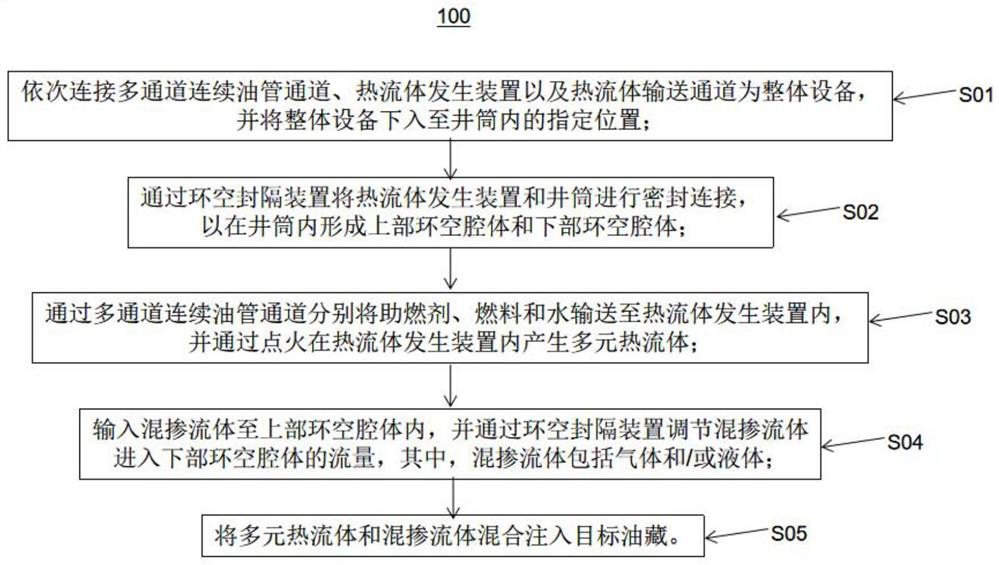

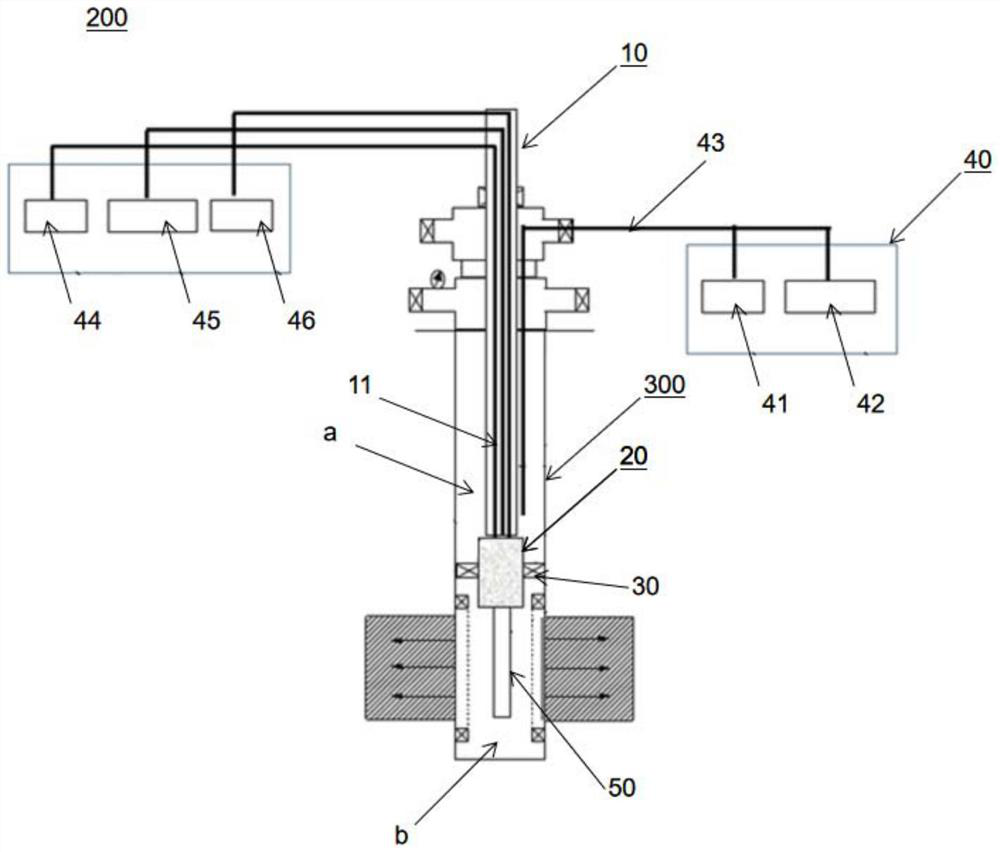

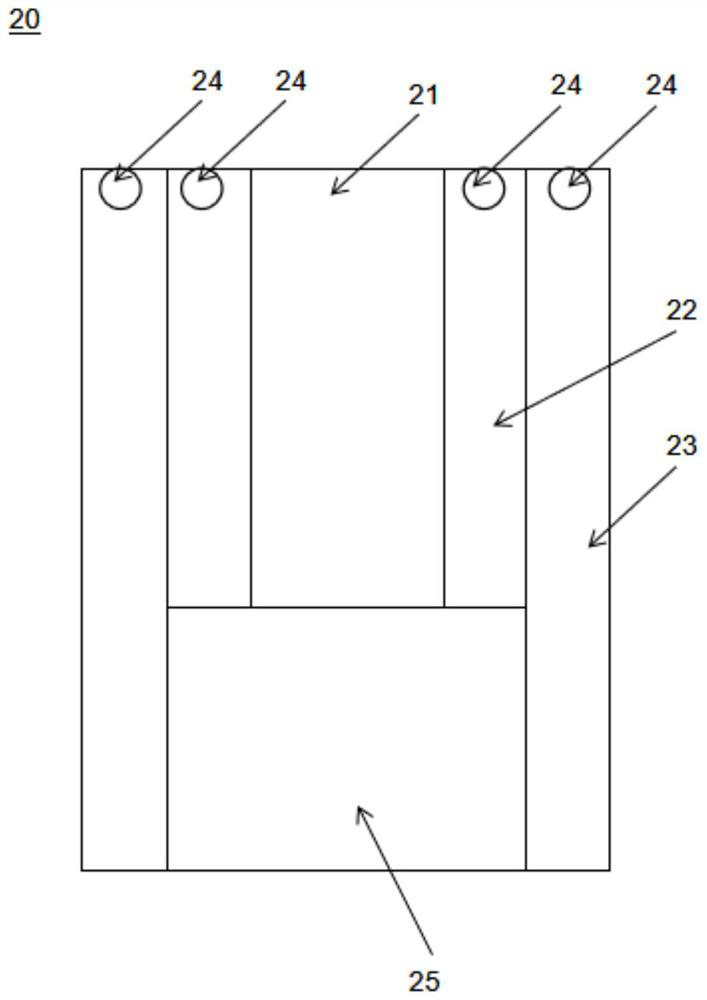

[0020] figure 1 A method flow chart of the method 100 for downhole thermal fluid generation based on multi-channel coiled tubing according to an embodiment of the present invention; figure 2 This is a schematic diagram of the system connection of the multi-channel coiled tubing-based downhole thermal fluid generating equipment 200 according to the embodiment of the present invention. combine figure 1 and figure 2 As shown, the method 100 for downhole thermal fluid generation based on multi-channel coiled tubing according to an embodiment of the present invention includes the following steps:

[0021] Step 1 S01 , sequentially connecting the multi-channel coiled tubing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com