System for controlling variable geometry equipment of a gas turbine engine especially comprising a guiding track connection

A control system and gas turbine technology, applied in gas turbine installations, engine control, engine components, etc., can solve the problems of increased risk of engine flameout and major disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

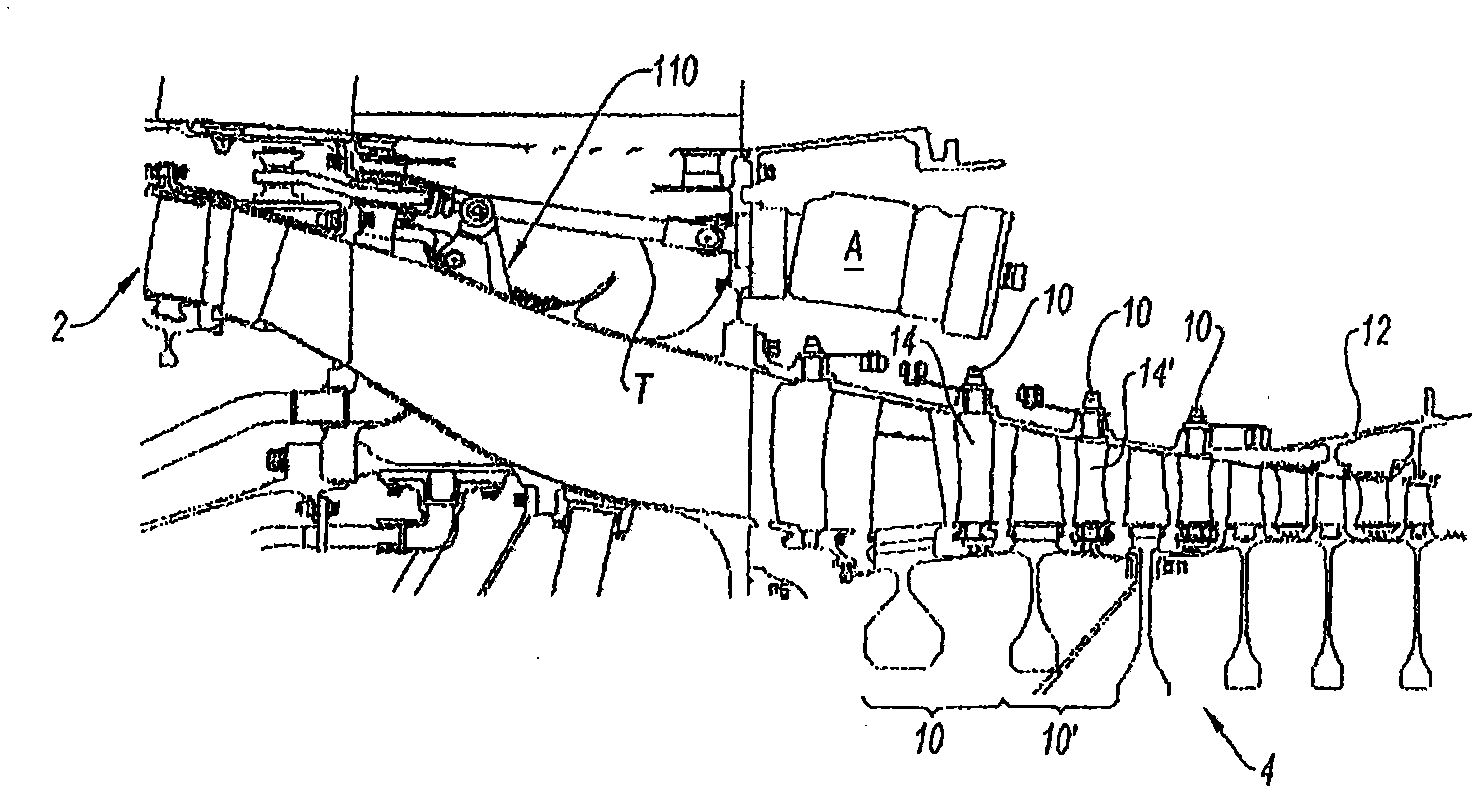

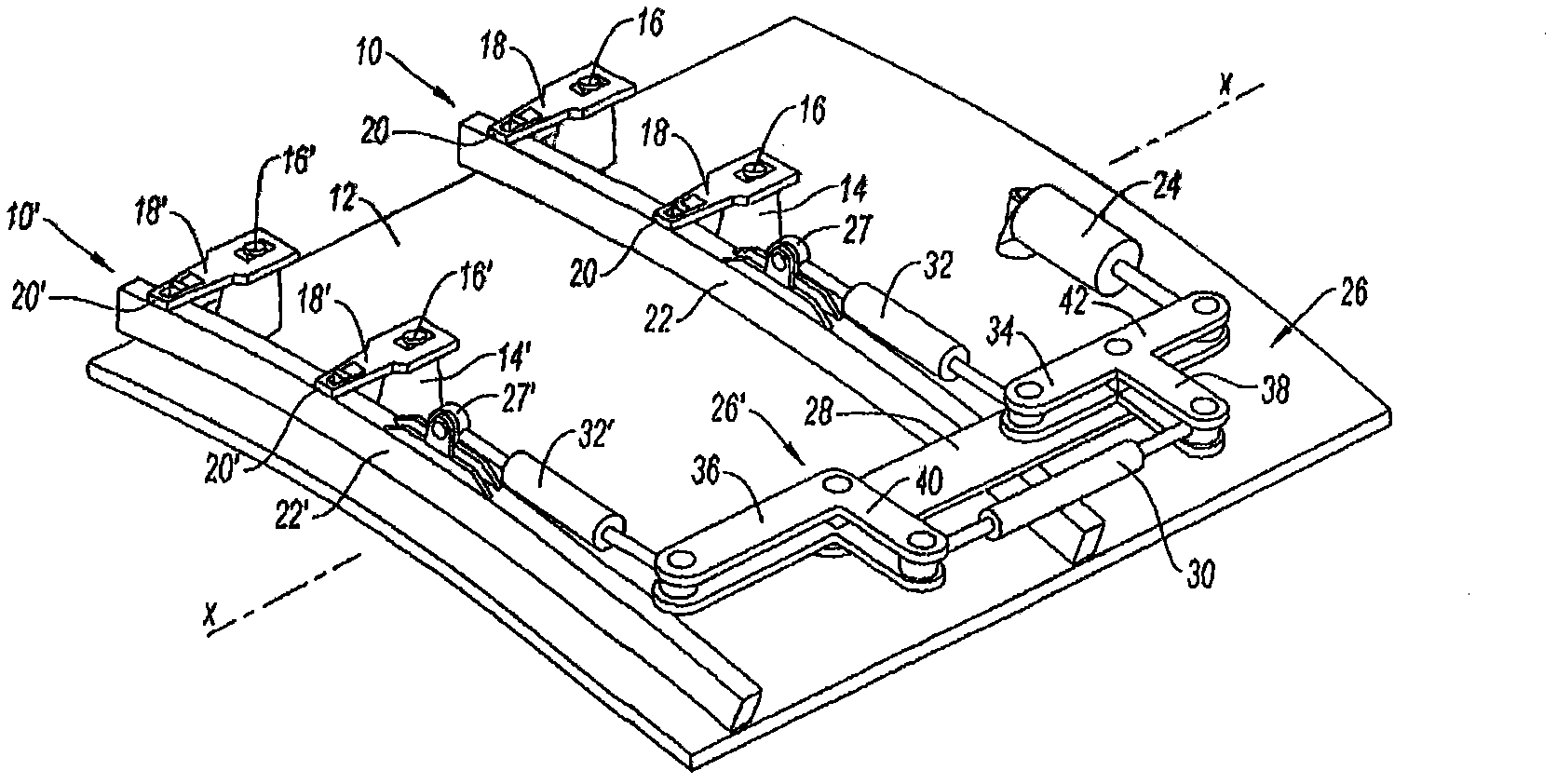

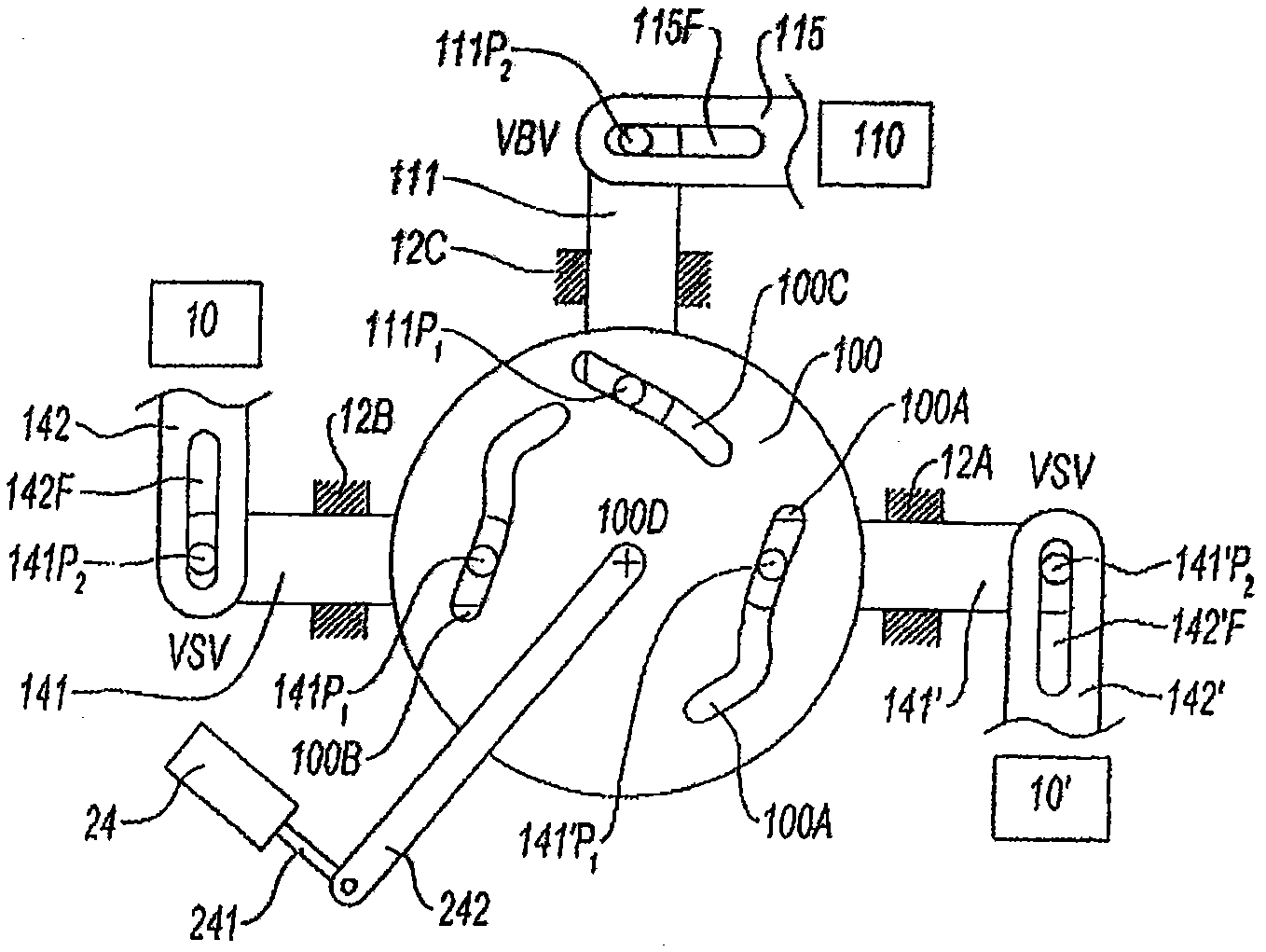

[0054] well known, such as figure 1 with figure 2 As shown, a gas turbine engine suitable for the aerospace field, such as a jet engine (represented here by the X-X axis), includes -- from upstream to downstream --- a fan, a low-pressure compressor 2, a high-pressure compressor 4, a combustor , a high-pressure turbine, a low-pressure turbine and a nozzle (not shown) for injecting gas. The high pressure compressor and the high pressure turbine are firmly fixed to the same shaft, called the high pressure shaft, and thus belong to the high pressure body of the engine or the first body rotating at the first speed, while the low pressure compressor and the low pressure turbine are firmly fixed to the same On the root shaft, called the low-pressure shaft, and therefore belongs to the low-pressure body of the engine or the second body rotating at the second speed.

[0055] In the following, the abbreviations LP and HP denote low pressure and high pressure, respectively.

[0056] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com