Quick relay protection test vehicle

A technology of relay protection and test vehicle, applied in the direction of circuit breaker testing, etc., can solve the problems of troublesome winding and unwinding, untidy line arrangement, low efficiency of winding and unwinding, etc., and achieve the effect of improving efficiency and convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

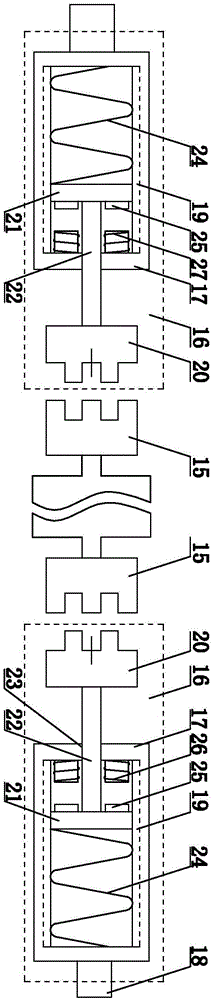

[0026] Embodiment 1: as figure 1 As shown, the relay protection rapid test vehicle of the present invention includes a vehicle body 1 and a device cover 2, a universal wheel 3 is respectively arranged at the four corners of the bottom of the vehicle body 1, and a pull rod 4 is provided on the side of the vehicle body 1. The body 1 is provided with a tester grid 5, a current test wire reel 6, a voltage test wire reel 7 and a power supply 8, and the current test wire reel 6 and the voltage test wire reel 7 are provided with a take-up and release roller 9, and the current A drive device 10 is arranged between the test wire reel 6 and the voltage test wire reel 7, the take-up and pay-off roller 9 is connected to the power output shaft of the drive device 10, the side of the car body 1 is provided with a control panel 11, and the drive device 10 is controlled by The panel 11 is connected to a power source 8 .

Embodiment 2

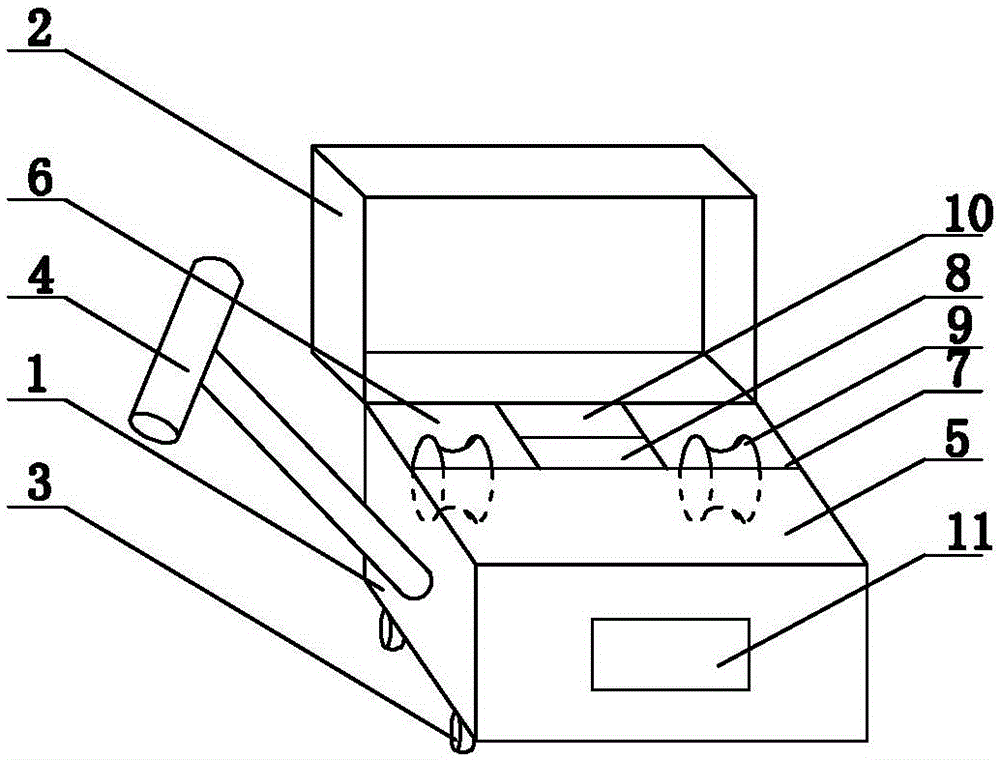

[0027] Embodiment 2: on the basis of the structure described in embodiment 1, as figure 2 As shown, the driving device 10 includes a motor 12, a dual output gearbox 13 and a clutch 14, the power end of the motor 12 is connected to the power supply 8 through the control panel 11, and the rotor of the motor 12 is connected to the power input end of the dual output gearbox 13 through a coupling , the two power output ends of the dual-output gearbox 13 are connected to the rotating shaft of the take-up and pay-off roller 9 through the clutch 14 respectively.

Embodiment 3

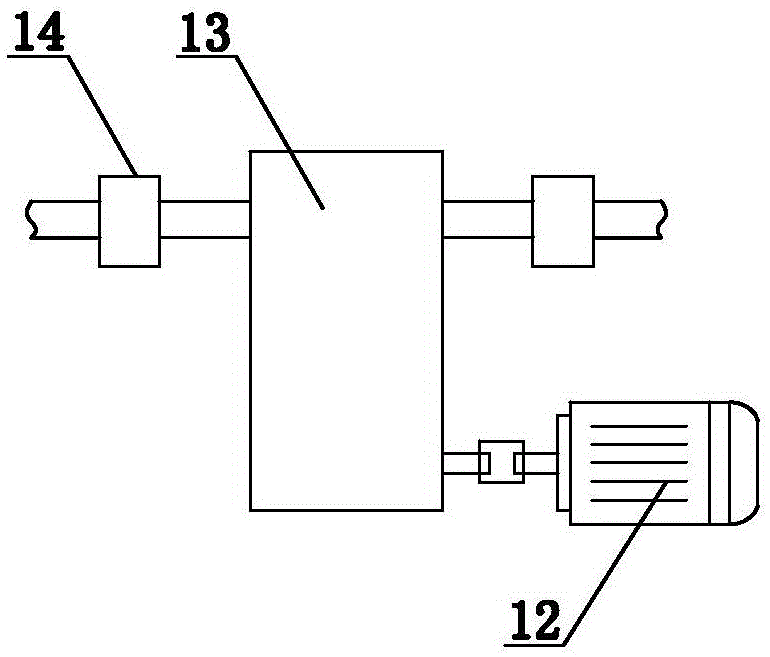

[0028] Embodiment 3: on the basis of the structure described in embodiment 2, as image 3As shown, the clutch includes an A part 15 and a B part 16, the A part 15 is connected with the power output end of the double output gearbox 13, the B part 16 includes a casing 17 and a connecting shaft 18, the connecting shaft 18 is connected to the end surface of the casing 17, and the casing 17 There are slide rails 19 inside, the B part 16 is provided with a mating head 20, the end of the mating head 20 is provided with a bottom plate 21, the mating head 20 and the bottom plate 21 are connected by a pillar 22, the pillar 22 passes through the opening 23 of the shell 17, and the two ends of the bottom plate 21 Located in the slide rail 19, a spring 24 is provided between the bottom plate 21 and the inner bottom surface of the housing 17, an armature 25 is provided on the top surface of the bottom plate 21, and an electromagnet A26 and an electromagnet B27 are respectively provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com