Belt conveyer capable of being instantly locked and unlocked

A belt conveyor, instantaneous locking technology, applied to conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as cargo vibration, pallet tipping, and threat to cargo transportation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

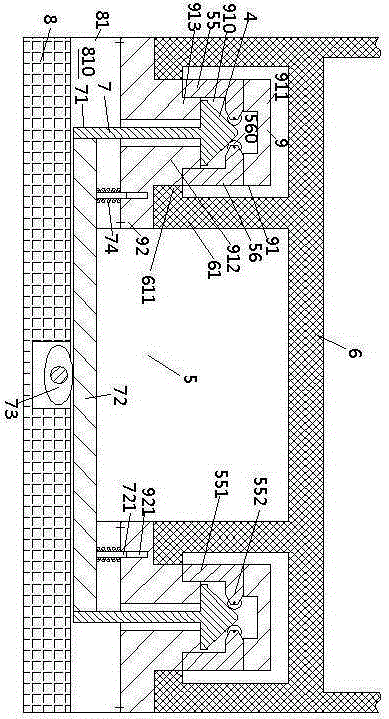

[0010] Combine below figure 1 The present invention will be described in detail.

[0011] A belt conveyor that can be locked and unlocked instantaneously according to an embodiment includes a conveyor belt assembly 5 and a cargo pallet device 6, and the conveyor belt assembly 5 includes flexible flexible belts with installation protrusions 81 fixedly arranged at the edges of both sides respectively. The belt 8 and the two positioning locking components 9 that are respectively firmly connected with the mounting protrusions 81 and arranged symmetrically, each of the positioning locking components 9 includes a bearing chassis 92 and a fixing mechanism fixedly connected with the bearing chassis 92. The cylindrical part 91, the fixed cylindrical part 91 includes a telescopic through hole 910 extending in a direction parallel to the plane of the flexible belt 8, a top wall part 911 located on the upper side of the telescopic through hole 910 and a The column root part 912 on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com