An Improved Dust Removal and Humidification Device for Rapier Looms

A technology of humidifying device and rapier loom, which is applied in looms, weaving, textiles and papermaking, etc. It can solve problems such as uneven yarn tension, achieve multifunctional functions, improve cleaning convenience, and ensure smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

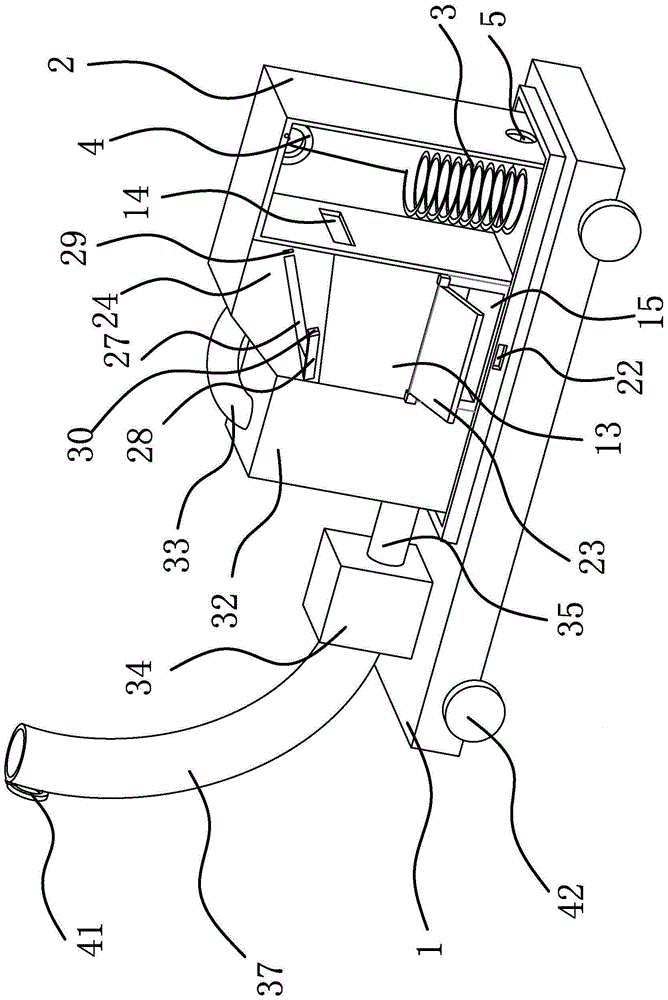

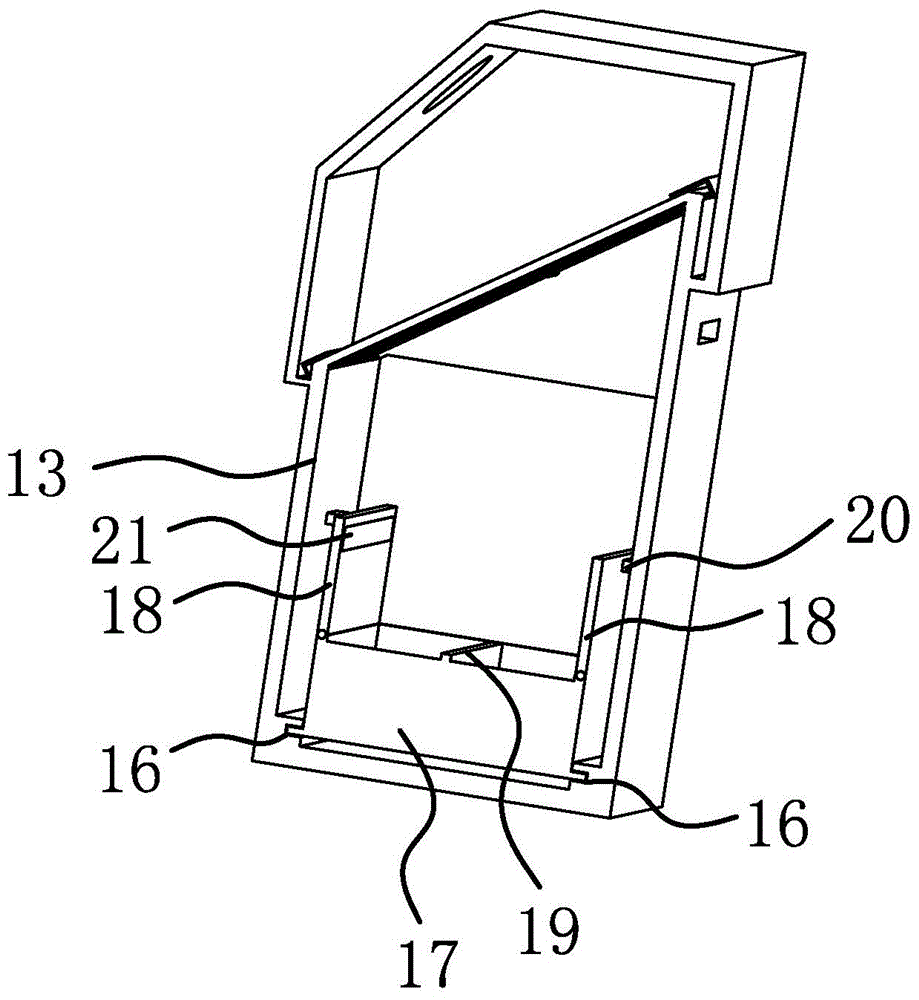

[0046] Such as figure 1 As shown, the dust removal and humidification device includes a line module, a dust storage module, a dust removal module, a humidification module and a bottom plate 1 .

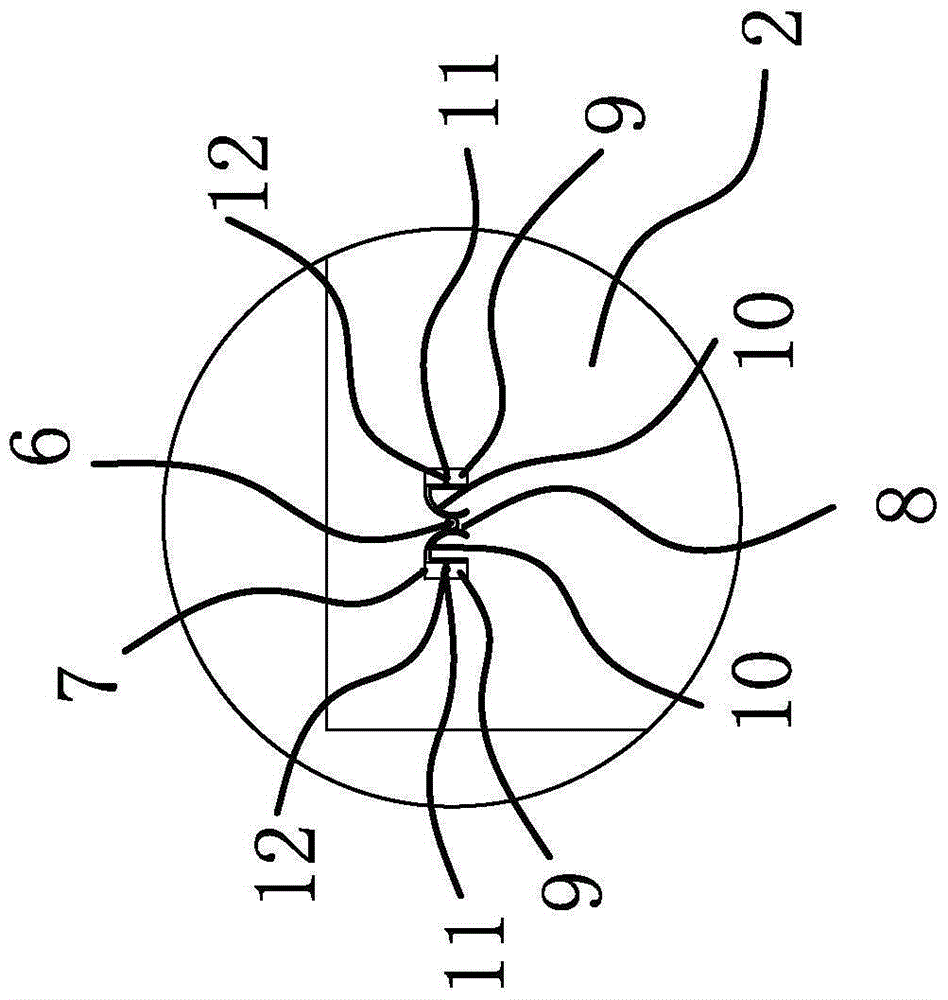

[0047] Such as figure 1 , figure 2 As shown, the thread setting module includes a thread setting box 2 arranged on the bottom plate 1, a weft thread 3 and a weft feeder 4 are arranged in the thread setting box body 2, and an air inlet 5 and an air inlet 5 are provided on the side wall of the thread setting box body 2. The wire outlet hole 6 corresponding to the weft feeder 4, the wire setting module also includes two elastic pieces 7 arranged on the side wall of the wire setting box 2, the two elastic pieces 7 are symmetrical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com