An annular bottom pressurizer

A pressurizer and annulus technology, applied in the direction of wellbore/well components, earthwork drilling and production, sealing/isolation, etc., can solve the problem of affecting the production layer cementing quality, unable to make up for pressure loss, and the bottom hole gas layer cannot be effectively compressed To improve cementing quality and make up for pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

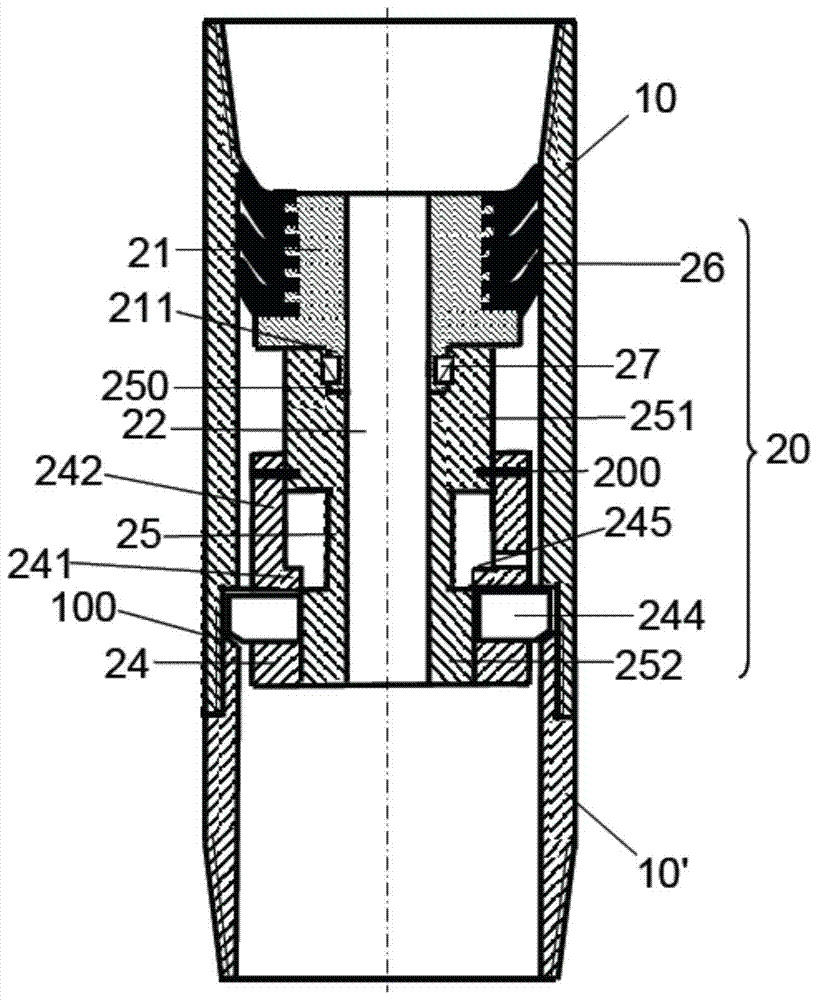

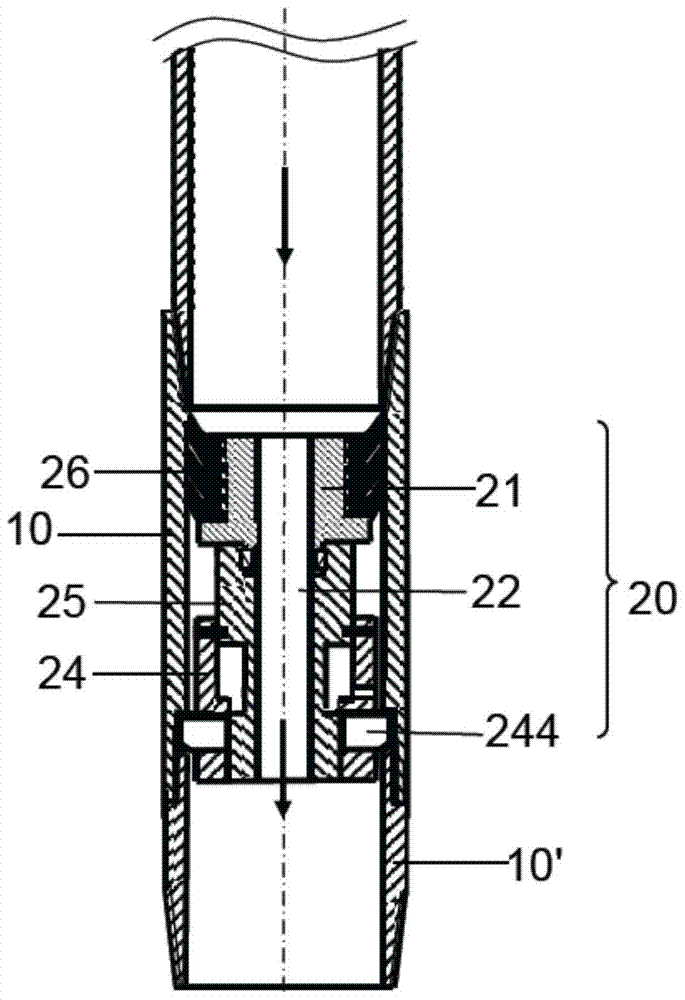

[0024] like figure 1 As shown, the annular bottom pressure device proposed by the present invention includes a housing 10, a seating pressure assembly 20 and an upper rubber plug 23 (see image 3 ). The seating pressure assembly 20 is disposed in the housing 10 , and the upper rubber plug 23 is used to block the fluid passing through the seating pressure assembly 20 to suppress pressure. The annulus bottom pressurizer of the present invention and its various parts will be described in detail below.

[0025] It should be noted that the annulus bottom pressurizer of the present invention is connected to the bottom of the casing so as to pressurize the annulus from the bottom of the well.

[0026] like figure 1 As shown, the casing 1 is a hollow pipe section for easy connection to the casing, and the upper and lower ends of the casing 10 are both formed with casing ladder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com