A Meshing Modeling Method of Spalled Gears Based on Mesh Stiffness

A meshing stiffness and meshing technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of not considering the influence of the meshing stiffness of the gear tooth root, and the meshing process of the peeling gear, etc., to improve the accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described in further detail below in conjunction with accompanying drawing:

[0045] A method for modeling spalled gear meshing based on meshing stiffness, comprising the following steps:

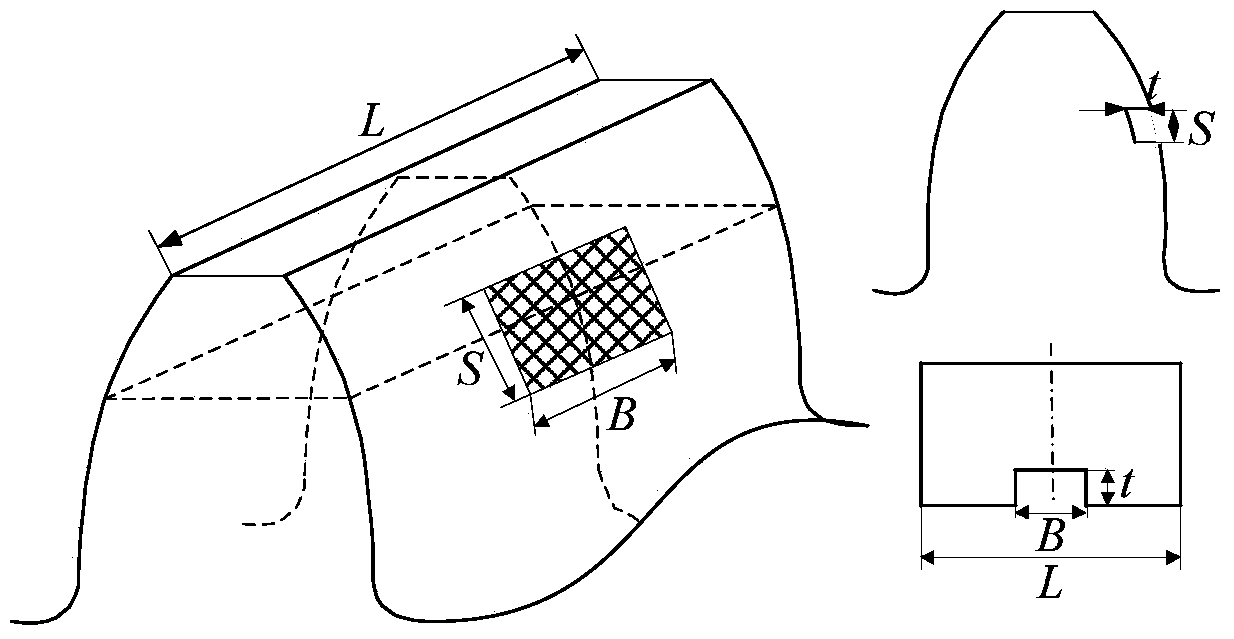

[0046] 1) Since the spalling of gear teeth generally occurs on the surface near the pitch line and close to the tooth root, it is assumed that the spalling occurs at the pitch line of the gear, the spalling area is a B×S rectangular area, and the spalling thickness is t. The spalling diagram is as follows figure 1 shown;

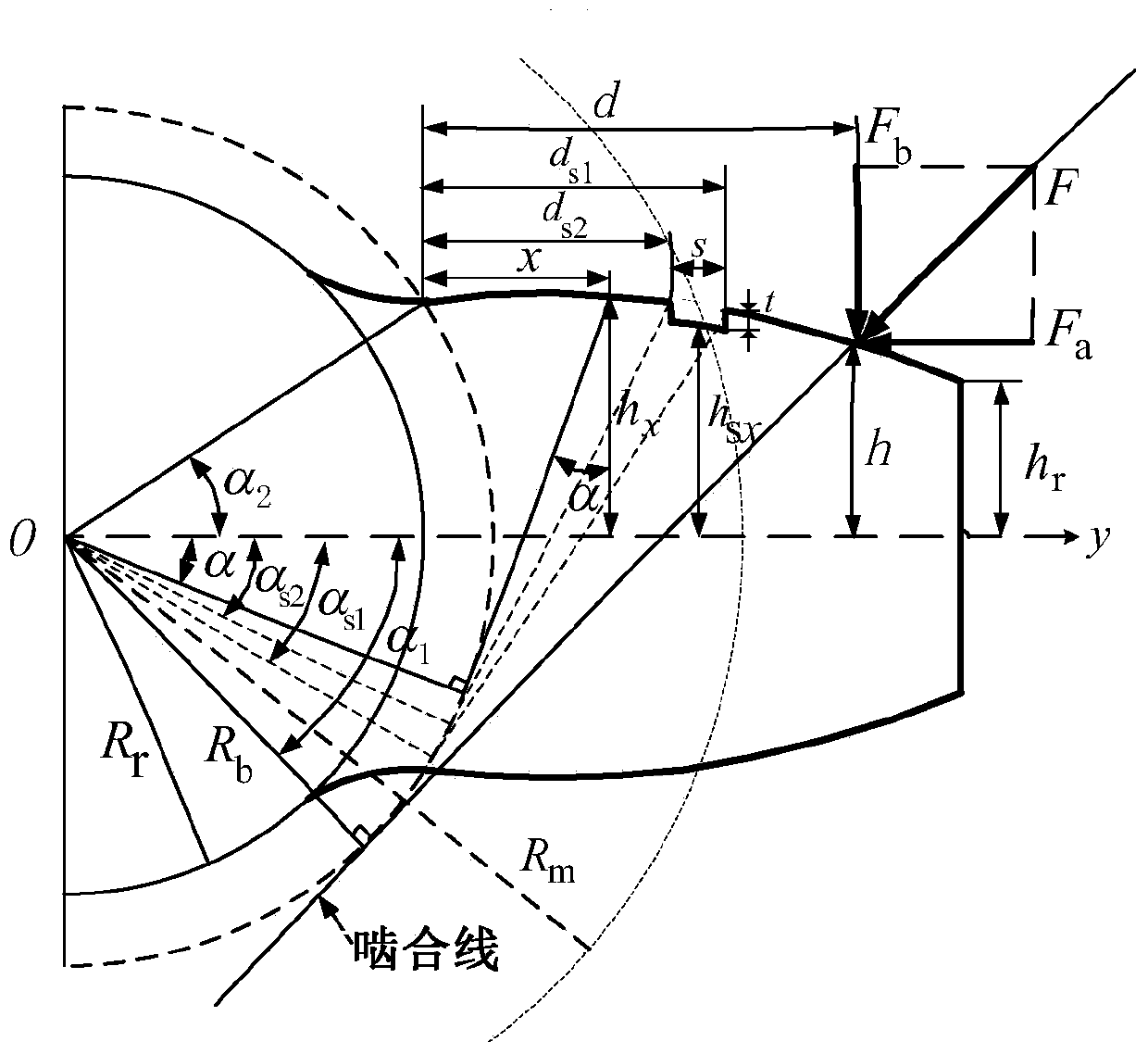

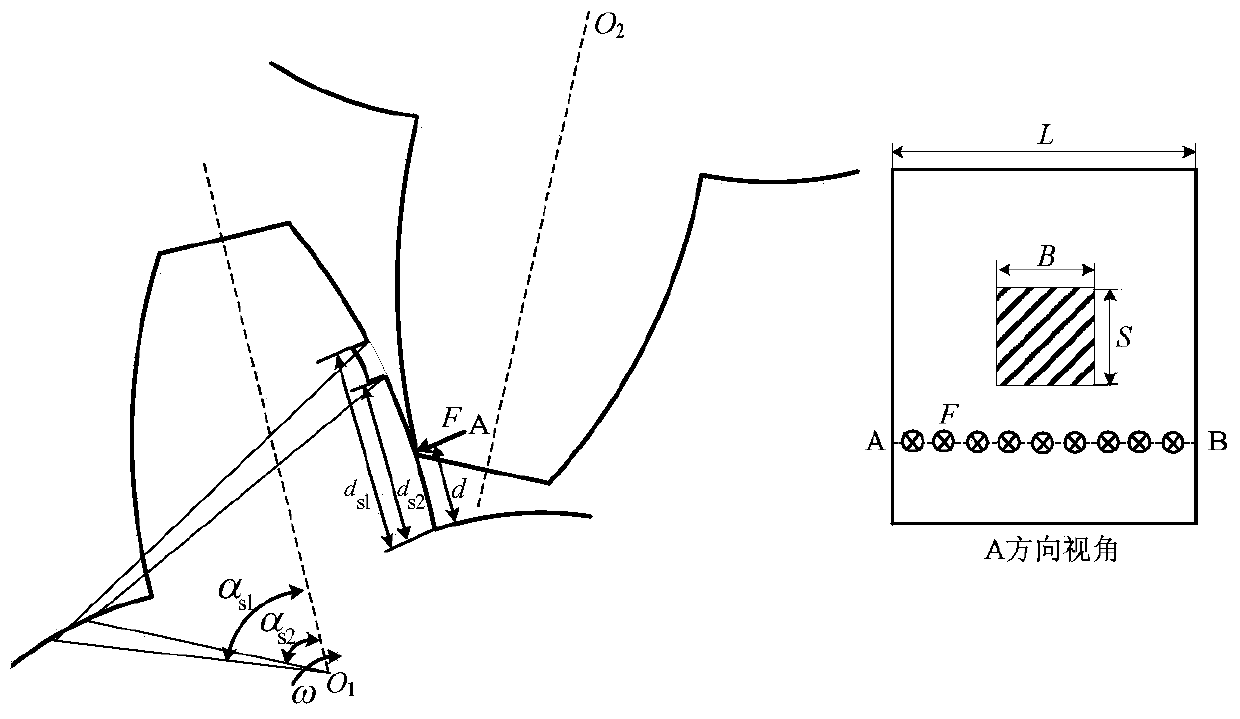

[0047] 2) Considering the influence of the dedendum on the meshing stiffness, the spalled tooth bearing the meshing force is simplified as a cantilever beam on the dedendum circle, and the force analysis is carried out on the spalled tooth. The force diagram is as follows figure 2 shown by figure 2 It can be seen that the transition arc between the base circle and the dedendum circle is regarded as a part of the cantilever beam, thus co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com