Blocking finger device of bending machine

一种折弯机、驱动装置的技术,应用在折弯机领域,能够解决定位精度低、不利精确微调、成本翻等问题,达到保证加工质量、保证定位精度、提高定位精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

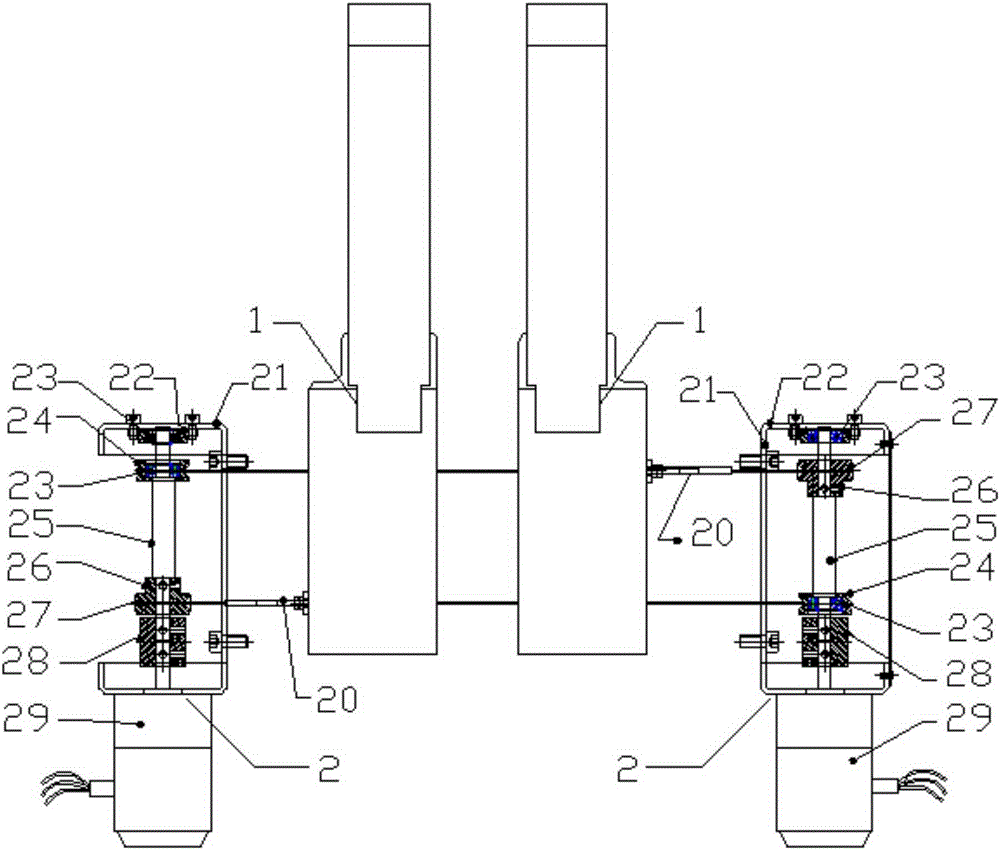

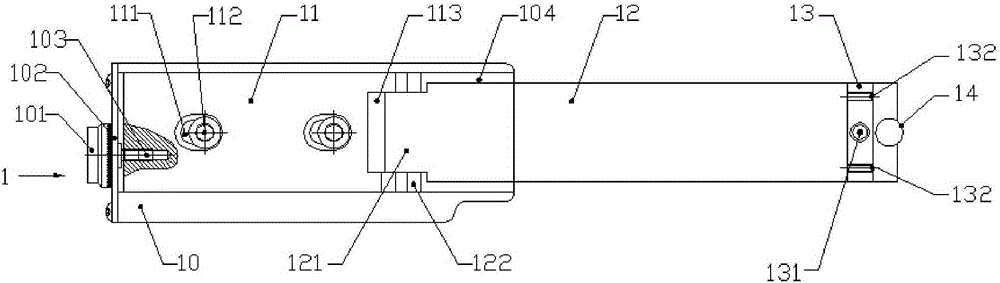

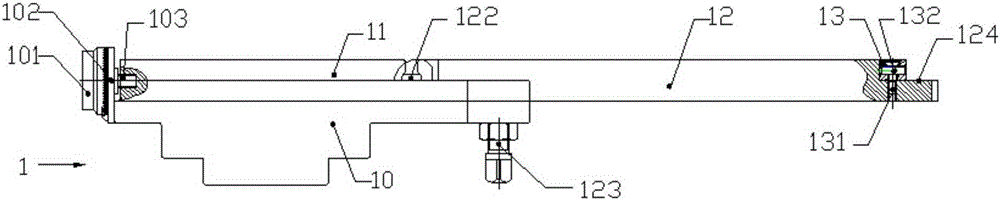

[0022] Such as figure 1 As shown, an automatic finger locking mechanism for a bending machine includes finger driving devices 2 arranged on the left and right sides of the bending machine. Finger 1, the finger 1 is slidably arranged on the Z-axis slide rail of the bending machine, and is driven by the finger drive device 2 to move left and right along the Z-axis slide rail.

[0023] Such as figure 1 As shown, specifically, the finger driving device 2 includes a driving base 21, the driving base 21 has an approximate U-shaped structure, and the driving shaft 25 is vertically and rotatably installed on the driving base 21, and the driving shaft 25 is driven by Driven by a motor 29, the driving shaft is axially equipped with a driving wheel 26 and a driven wheel 24, the driving wheel and the driving shaft are fixed, a bearing 23 is arranged between the driven wheel and the driving shaft, and the driving shafts on the left and right sides The upper driving wheel and the driven w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com