Contact line grinding machine of rigid contact net

A technology of rigid contact and contact line, applied in the direction of grinding machine, grinding drive device, grinding machine parts, etc., can solve the problems of people's safety hazards in high-altitude work, affecting physical health, low grinding efficiency, etc., to reduce labor Strength, easy operation and maintenance, high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

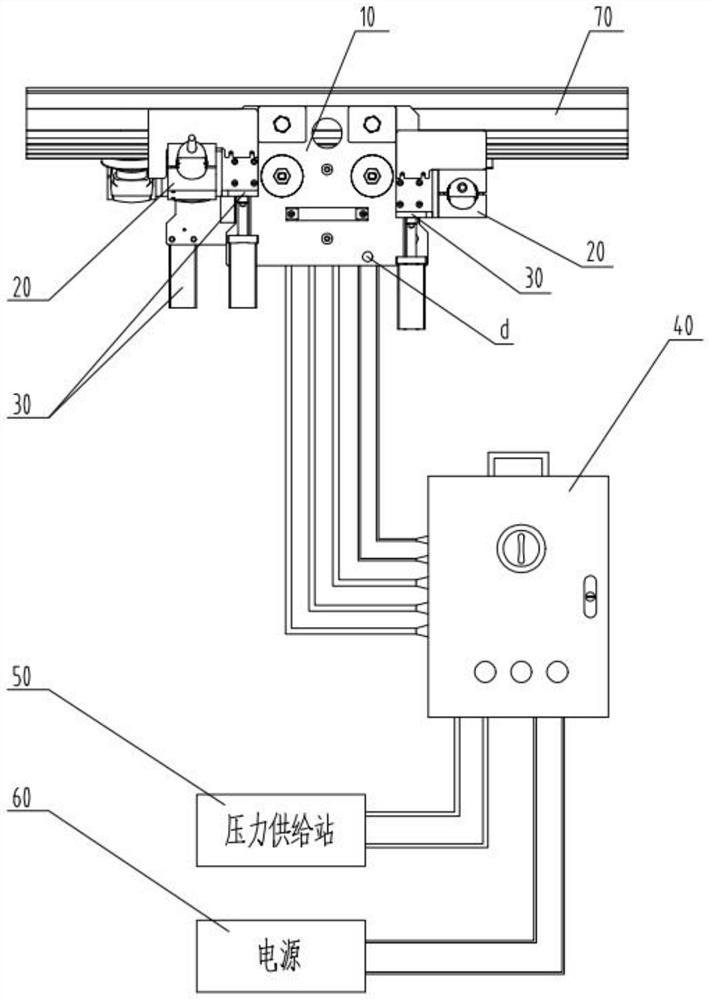

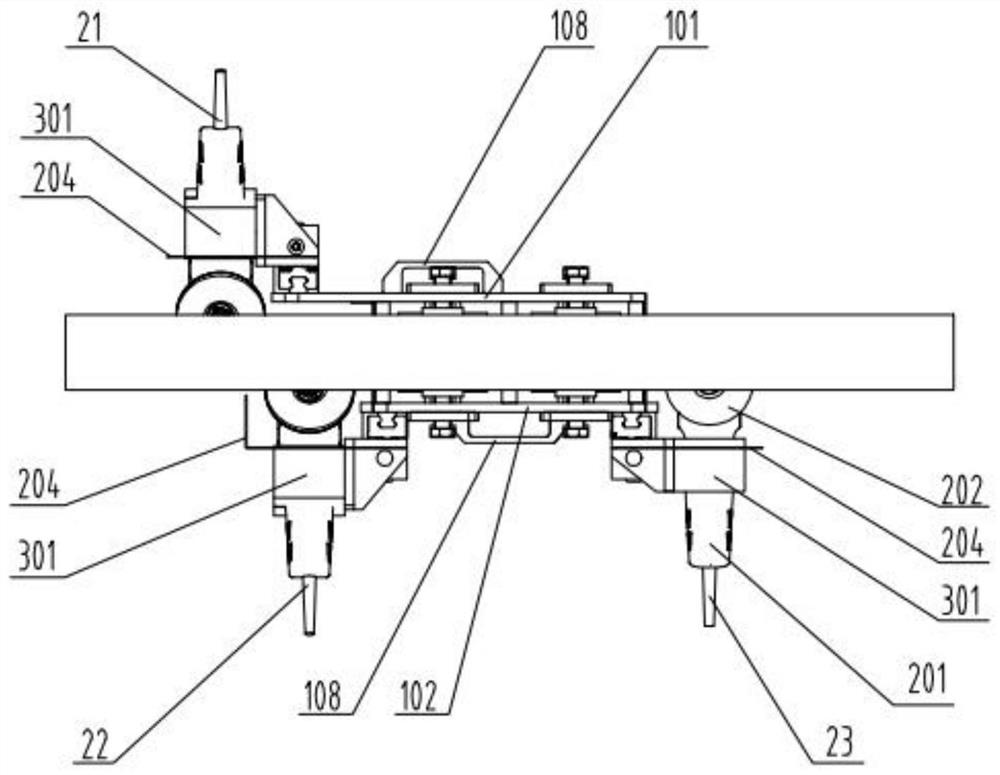

[0036] The contact line grinder for rigid catenary of the present invention includes a trolley mechanism 10 , a grinding mechanism 20 , an angle adjustment mechanism 30 , a control mechanism 40 , a pressure supply station 50 and a power supply 60 . The pressure supply station adjusts the pressing force of the grinding mechanism on the contact line 702 under the action of the control mechanism; the angle adjustment mechanism adjusts the grinding angle of the grinding mechanism according to the degree of wear of the contact line of the rigid suspension catenary 70 .

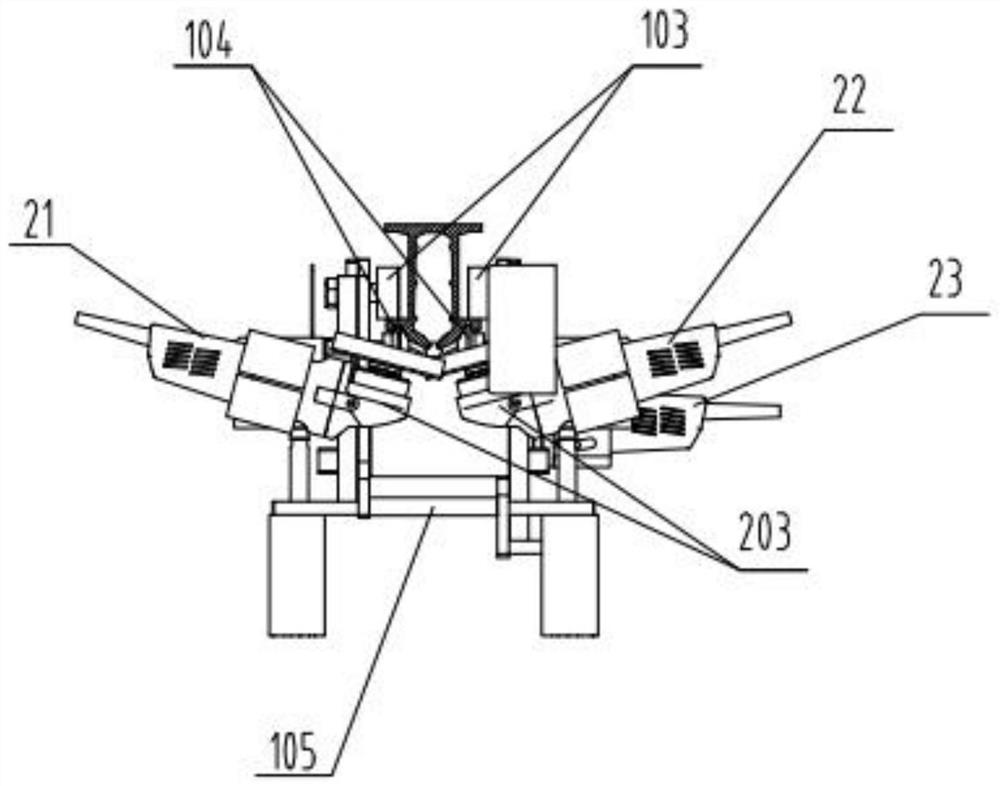

[0037] The trolley mechanism 10 includes a side plate assembly, a support beam 105, a suspension running assembly and a V-groove running assembly. The suspension running assembly rolls on the upper end surface of the bus bar 701, and the V-groove running assembly fits on the lower end surface of the bus bar.

[0038] The suspension traveling assembly includes a suspension traveling wheel 103 and a suspension traveli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com