Traction device and logistics transfer car

The technology of a traction device and a locking mechanism is applied in the directions of traction connectors, vehicle parts, transportation and packaging, etc., and can solve the problems of easy damage of the towing mechanism and the locking mechanism, easy to cause safety accidents, high labor intensity of workers, etc. Achieve the effect of avoiding collision and injury, reducing the proportion of work-related injuries, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

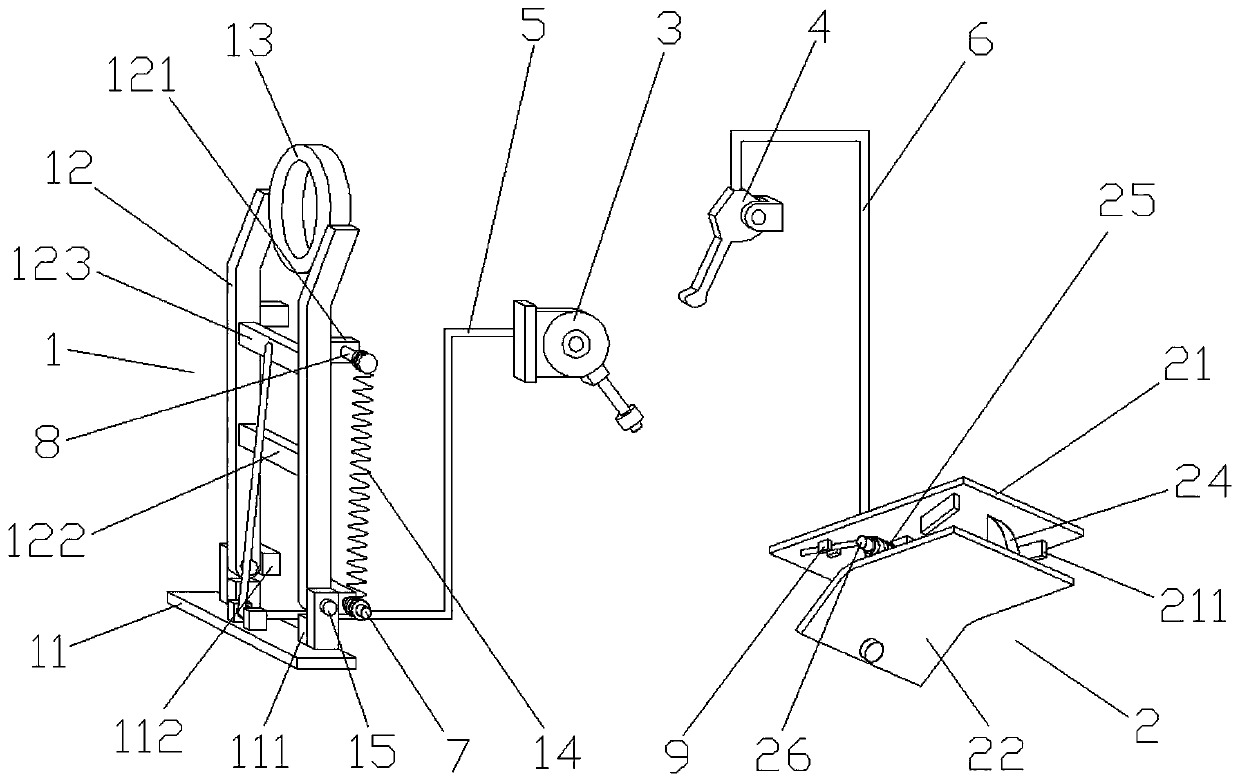

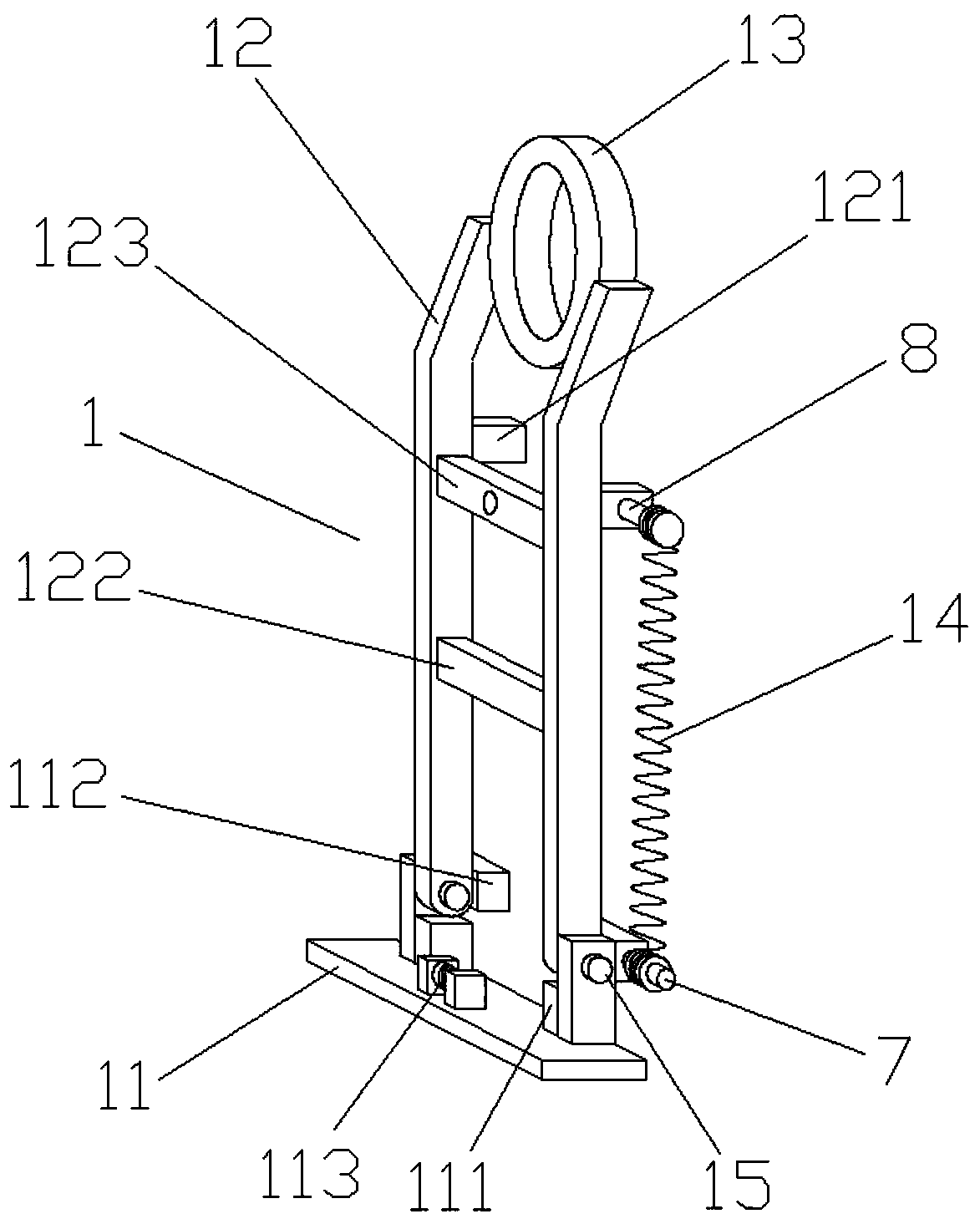

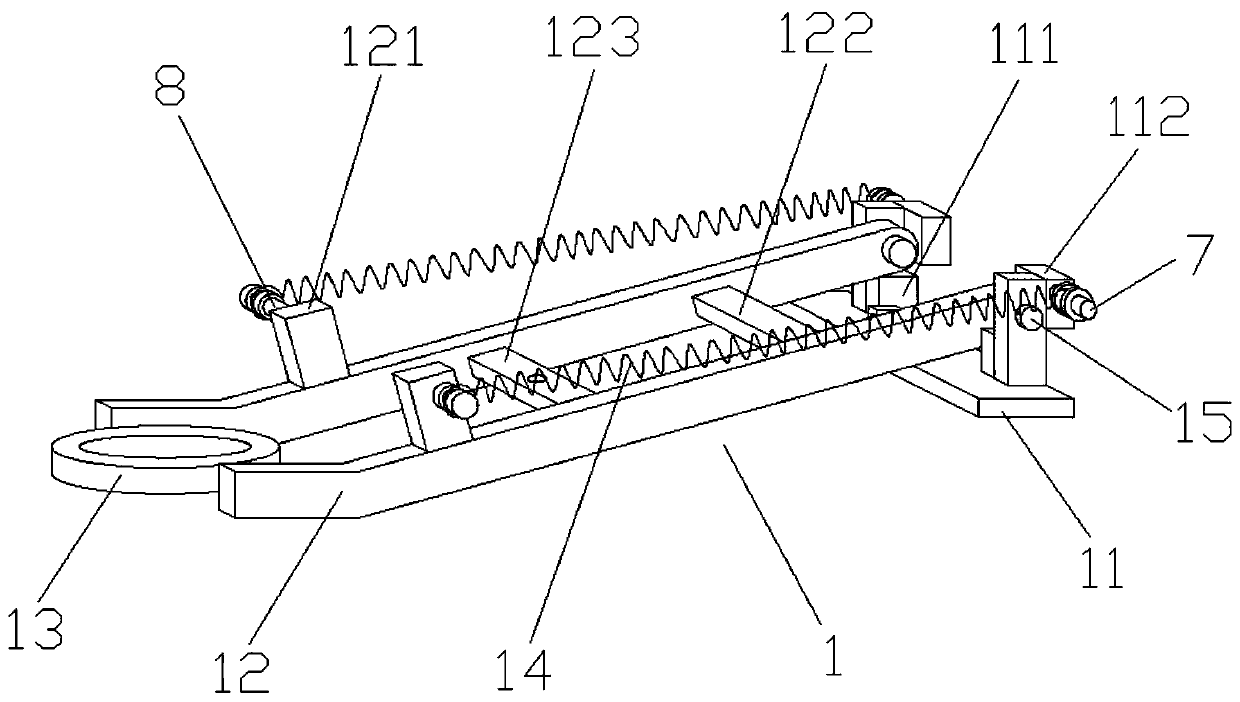

[0024] Embodiment 1 discloses a kind of traction device, such as figure 1 As shown, it includes a trailer mechanism 1, a locking mechanism 2 buckled with the trailer mechanism 1, a hand throttle wrench 3 and a brake handle 4. The hand throttle wrench 3 is connected to the trailer mechanism 1 through a first flexible shaft 5, and the brake The 4 is connected with the locking mechanism 2 through the second flexible shaft 6; as figure 2 and image 3As shown, the towing mechanism 1 includes a fixed seat 11, two tow bars 12, a hanging ring 13 and a tension spring 14, and the bottom ends of the two tow bars 12 are respectively hinged with the front and rear ends of the fixed seat 11 through the first hinge shaft 15. , the hanging ring 13 is fixedly installed between the tops of the two tow bars 12, specifically, the two sides of the hanging ring 13 are respectively welded and fixed to the inner side walls of the tops of the two tow bars 12, the tow bar 12 is in a broken line shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com