Gas storage reservoir salt cavern vertical segmented cavity dissolving method

A gas storage and salt cavern technology, which is applied to earth drilling, mining equipment, mining equipment, etc., can solve the problems of time-consuming, etc., and achieve the effects of reducing the construction period, improving efficiency, and increasing the cavity-building speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention provides a method for vertically segmented cavity dissolution of a salt cavern of a gas storage to solve the technical problem of too long time-consuming existing in the cavity-building process in the prior art.

[0037] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

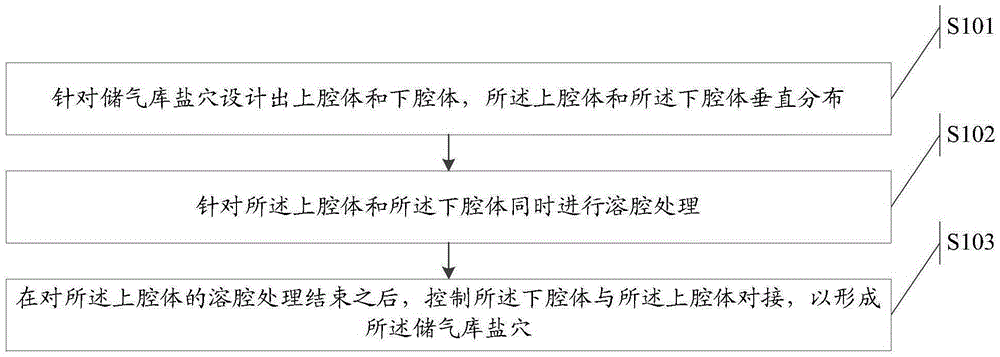

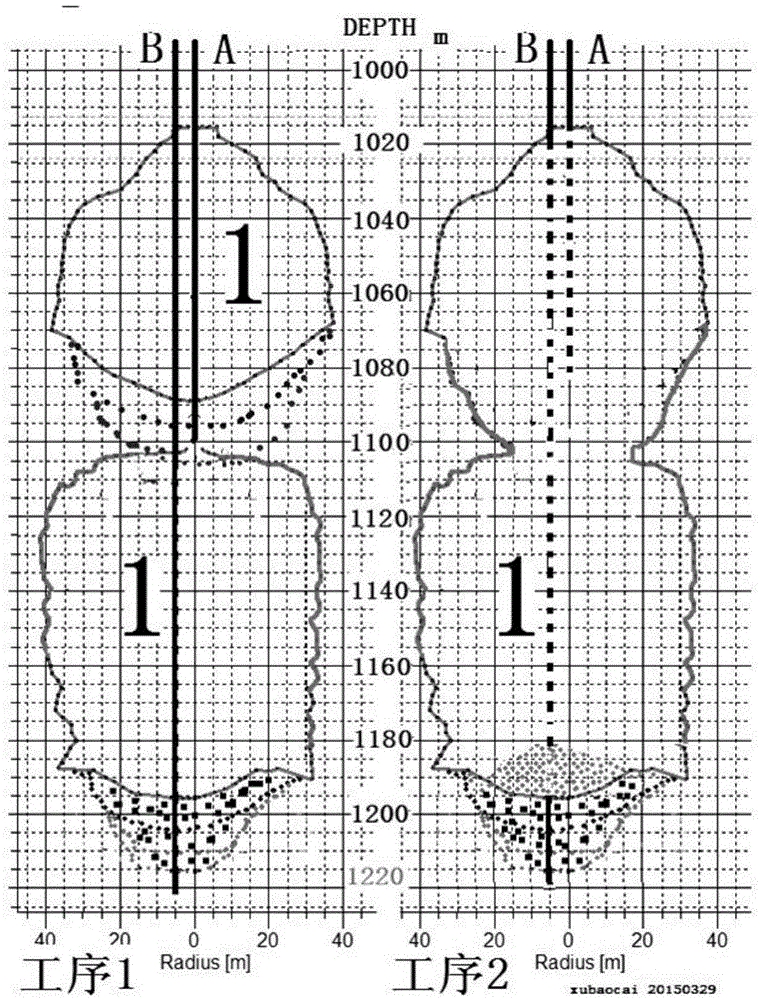

[0038] Provided is a gas storage salt cavern vertically segmented cavity dissolution method, comprising: designing an upper cavity and a lower cavity for the gas storage salt cavern, the upper cavity and the lower cavity are vertically distributed; The upper cavity and the lower cavity are subjected to cavity dissolution treatment at the same time; after the cavity dissolution treatment of the upper cavity is completed, the lower cavity is controlled to dock with the upper cavity to form the gas storage Library salt cave. That is to say, the salt cavern of the gas storage can be divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com