Technology for using twin-well asymmetrical brine collection to quickly build salt cavern storage cabin

An asymmetric and technological technology, which is applied in the field of rapid construction of salt cavern storage by asymmetrical brine extraction in double wells, can solve the problems of small distance between two wells, limited effect of cavity building speed, and complicated process, so as to reduce the cost of cavity building, The effect of increasing the cavity-making speed and simplifying the cavity-making process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

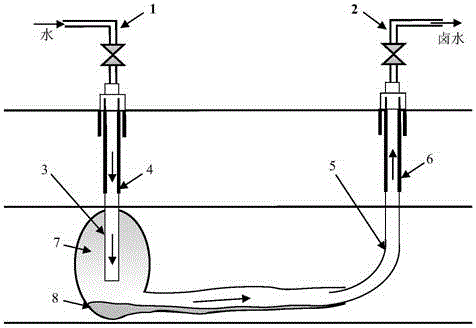

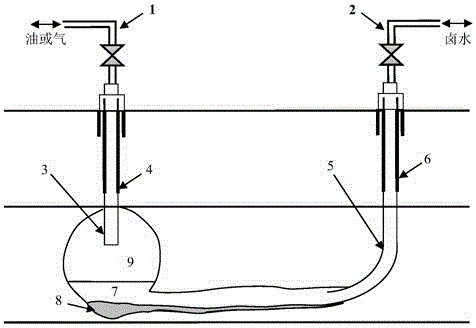

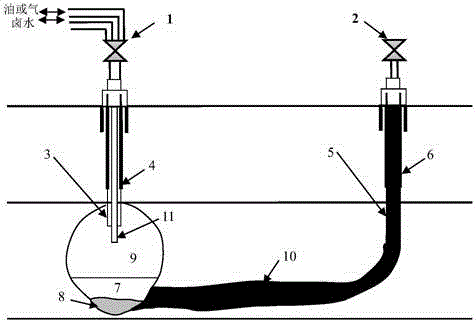

[0042] For salt deposits (the burial depth is -1000 ~ -1800m, the total thickness is about 800m), the rapid construction of salt cavern storage technology is adopted by double-well asymmetrical brine mining, which is realized through the following steps:

[0043] (1) Arrange two salt wells (well spacing 300m) in the mining area and realize horizontal connection, one of which is vertical well 1 (well number is Z1), and the other well is horizontal well 2 (well number is S1);

[0044] (2) In the two salt wells, the running position of production casing 3 in Z1 is -1780m, and the running position of production casing 5 in S1 is -1600m;

[0045] (3) Use the production casing of Z1 to inject water into the lower salt group, and the saturated or nearly saturated brine is extracted from the production casing 5 of S1 through the downhole communication channel;

[0046] (4) After 16 months of water solution mining, use sonar cavity measurement technology to measure the cavity size and ...

Embodiment 2

[0054] For salt deposits (the burial depth is -900 ~ -1400m, the total thickness is about 500m), the rapid construction of salt cavern storage technology is adopted by double well asymmetrical brine extraction, which is realized through the following steps:

[0055] (1) Arrange two salt wells (well spacing 250m) in the mining area and realize horizontal connection, one of which is vertical well 1 (well number is Z2), and the other well is horizontal well 2 (well number is S2);

[0056] (2) In the two salt wells, the running position of production casing 3 in Z2 is -1380m, and the running position of production casing 5 in S2 is -1250m;

[0057] (3) The production casing of Z2 is used for water injection and water-soluble mining of the lower salt group, and saturated or nearly saturated brine is extracted from the production casing 5 of S2 through the downhole communication channel;

[0058] (4) After 12 months of water solution mining, use sonar cavity measurement technology t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com