Cover beam external prestressing reinforcing structure and construction method thereof

A technology for external prestressing and reinforcing structures, applied in bridge reinforcement, bridges, bridge maintenance, etc., can solve the problems of small vertical component force and unsatisfactory reinforcement effect, so as to reduce friction, improve flexural reinforcement effect, and improve reinforcement effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

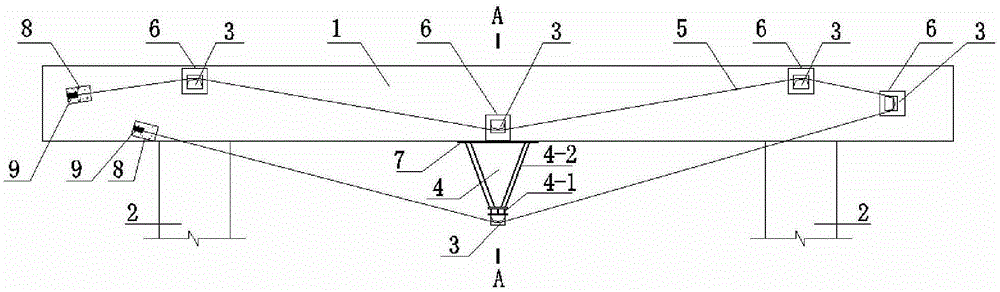

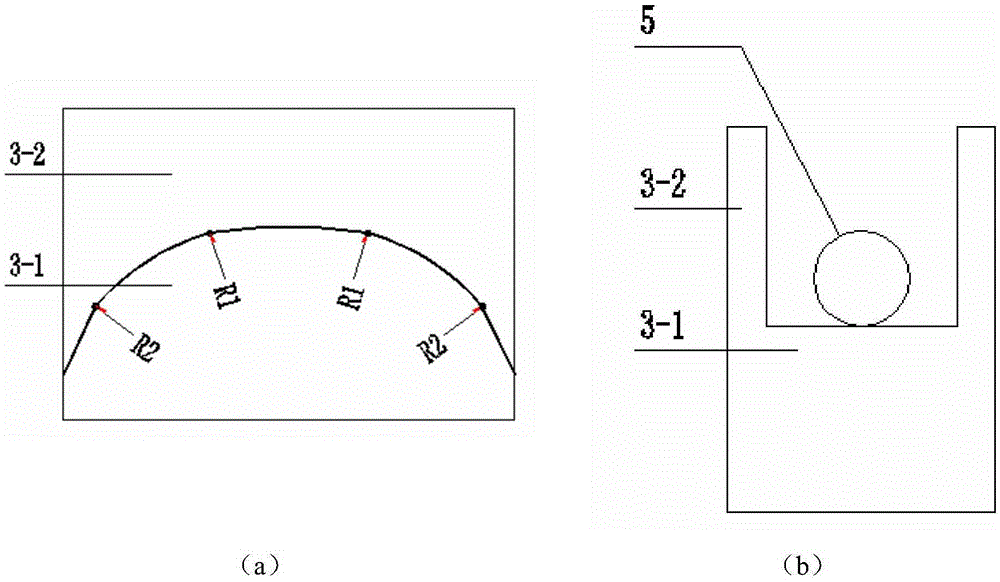

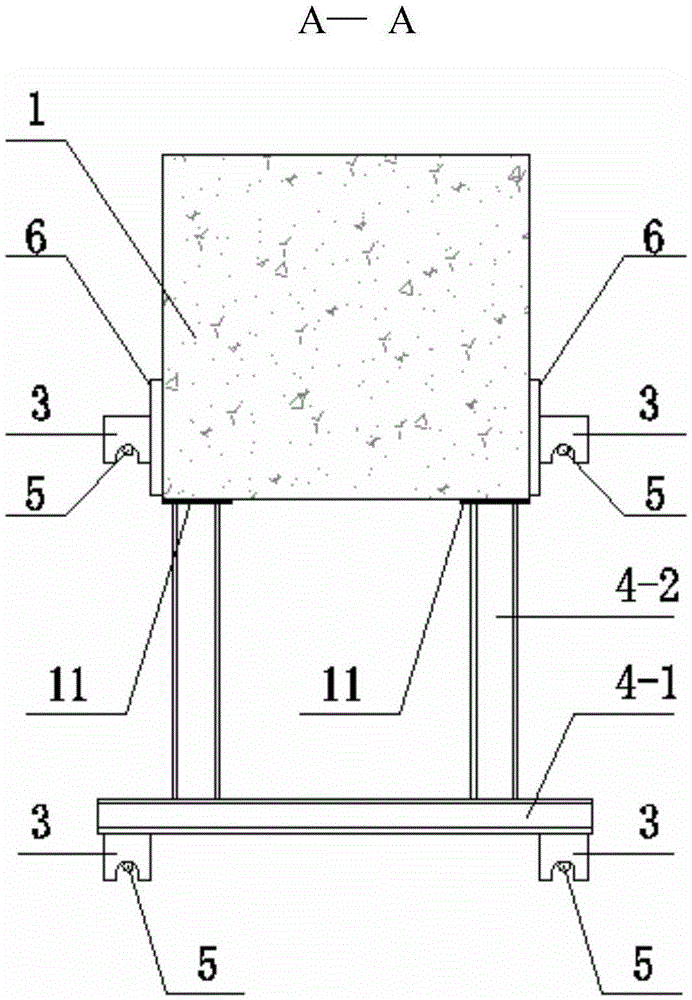

[0036] This embodiment is to carry out external prestressing reinforcement on the pier cover beam of a double-column ordinary reinforced concrete structure bridge of a highway bridge in Shenyang. The superstructure of the bridge is a prefabricated small box girder with a span of 25m and a bridge deck width of 16m. The substructure is double-column ordinary reinforced concrete pier cover beam, the concrete label of the cover beam is C30, and the section of the cover beam is 160cm wide and 140cm high. There are vertical cracks at the middle and lower edge of the cover beam due to insufficient bending moment, and the cover beam must be reinforced against bending.

[0037] The external prestressed reinforcement structure of the cover beam adopts OVM.A15-7 external prestressed steel beams, and the tension Ts of external prestressed steel beams is 911.4kN. Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com