Torque output tool

A torque output and tool technology, which is applied in the field of torque output tools, can solve problems such as the gap between the bit and the shake, the output shaft only has the rotation function, and the increase in cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0058] The present invention provides a torque output tool, which may specifically be an electric screwdriver.

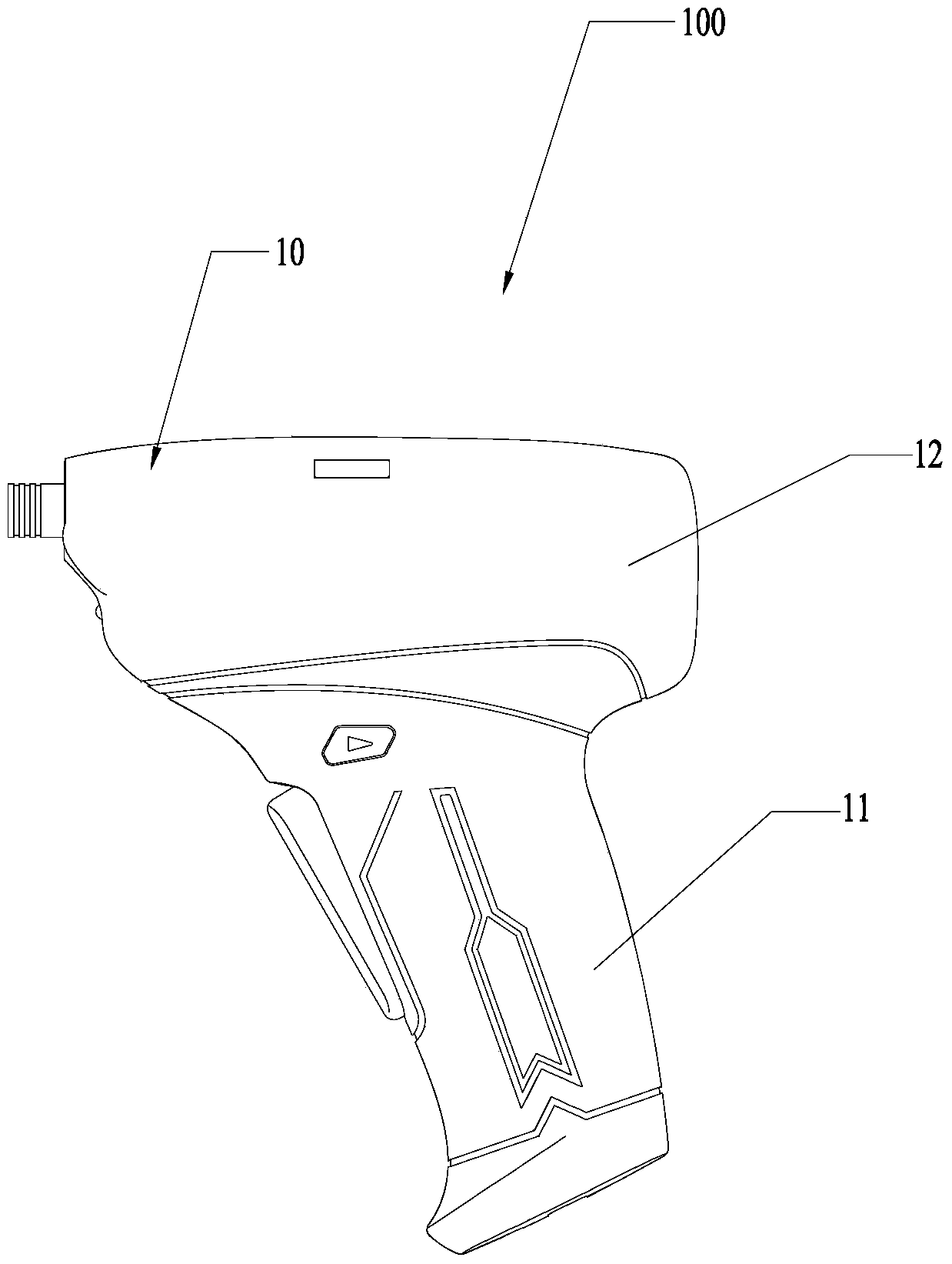

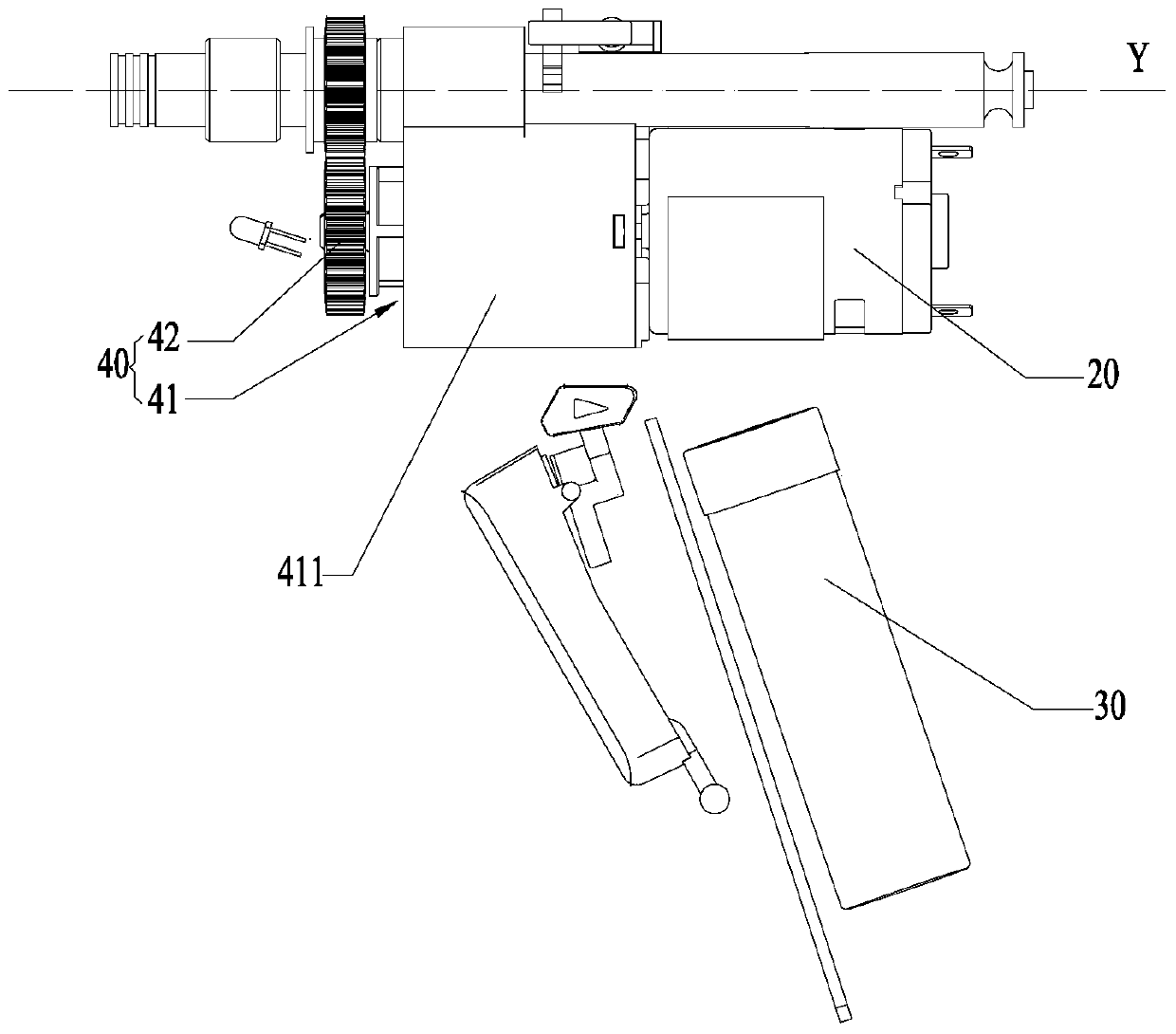

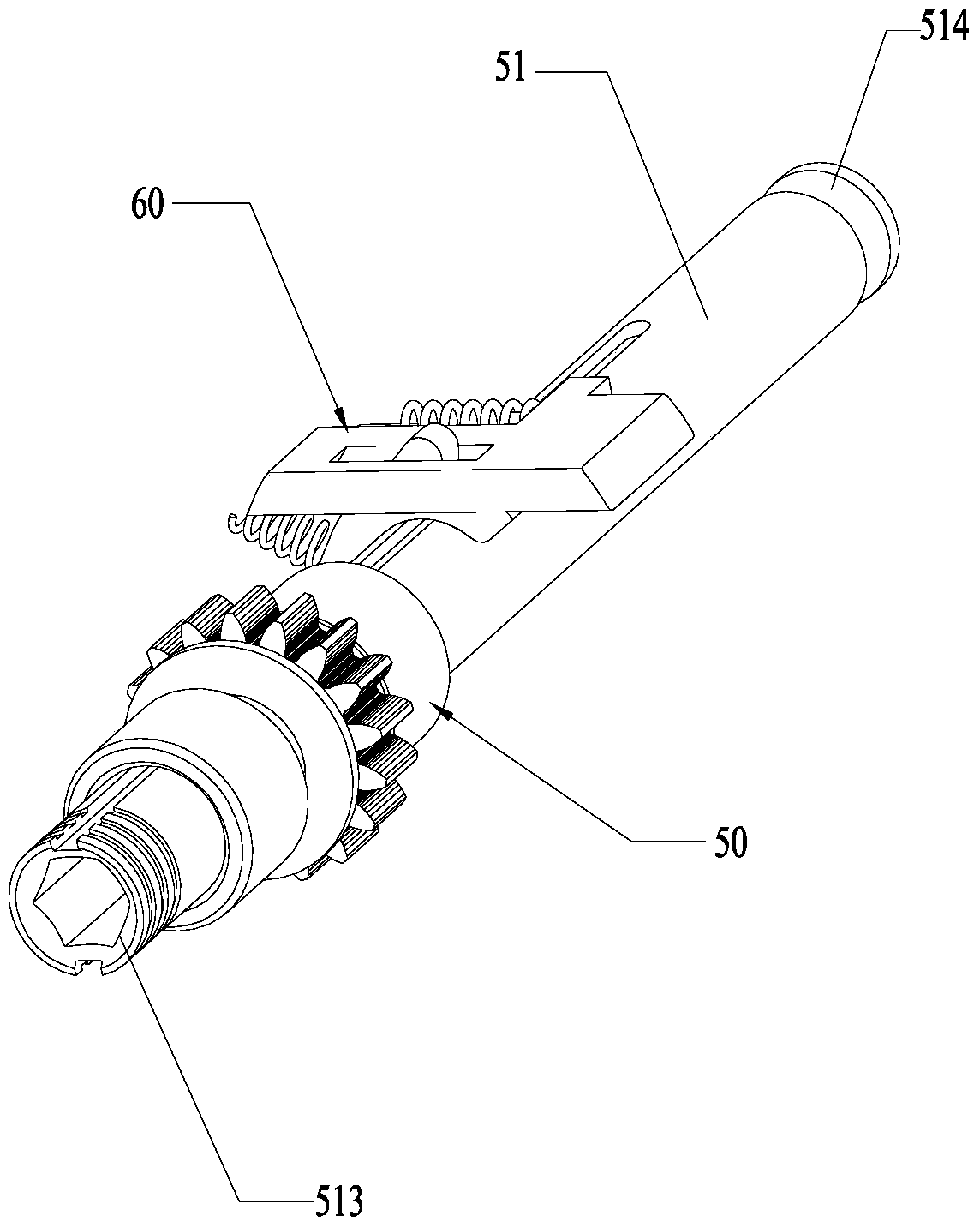

[0059] Please refer to Figure 1 to Figure 7 , The torque output tool 100 of this embodiment includes: a housing 10 , a prime mover 20 , a power source 30 , a transmission assembly 40 , a torque output assembly 50 , and a locking assembly 60 .

[0060] The casing 10 is used as the shell of the torque output tool 100, and a part of it is used to form a handle 11 for the operator to hold. The inside of the handle 11 can also accommodate the power source 30, and the other part is used to form the main engine cavity 12, and the main engine cavity 12 accommodates A prime mover 20, a power source 30, a transmission assembly 40, a torque output assembly 50, and a locking assembly 60 are provided. The prime mover 20 drives the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com