Power-split continuously variable transmission apparatus having summing planetary transmission

A stepless transmission and transmission technology, applied in transmission, friction transmission, mechanical equipment, etc., can solve problems such as the inability to realize the vehicle operating range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

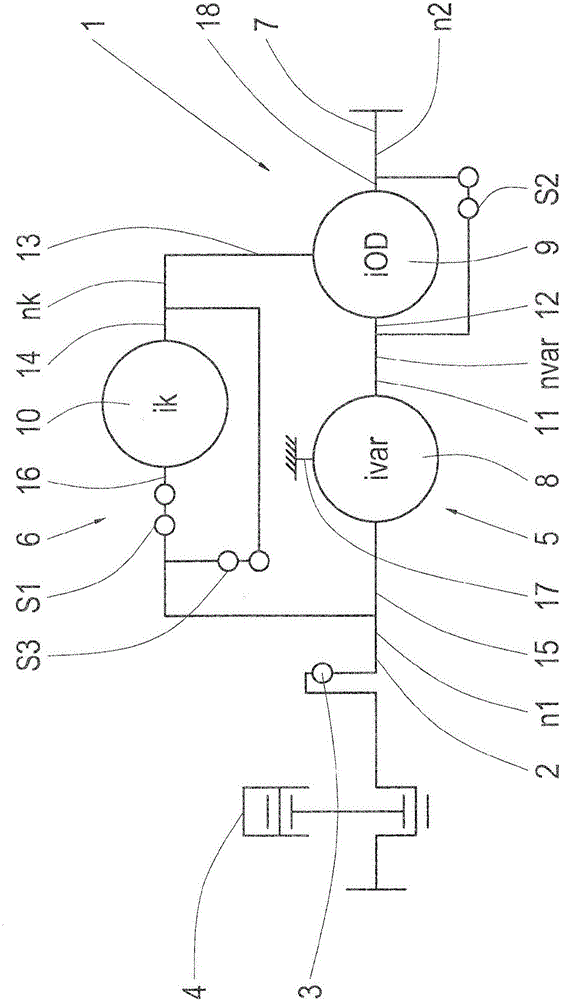

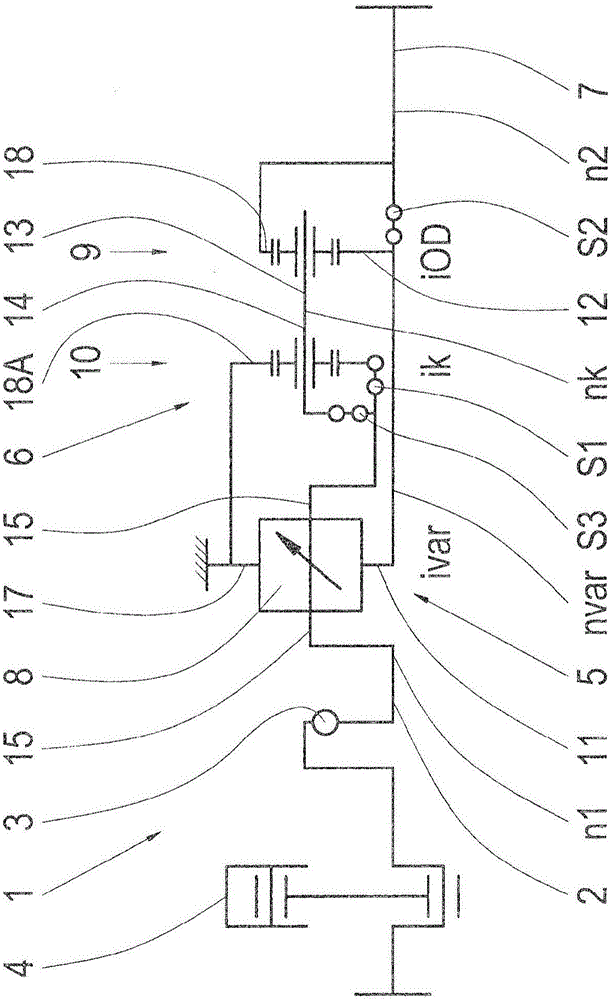

[0041] figure 1 A schematic diagram of a power-split continuously variable transmission 1 is shown, which is operatively connected to a drive machine 4 via a torsional vibration damper 3 in the region of the transmission input shaft 2 . The drive engine 4 is designed here as an internal combustion engine, preferably a diesel internal combustion engine.

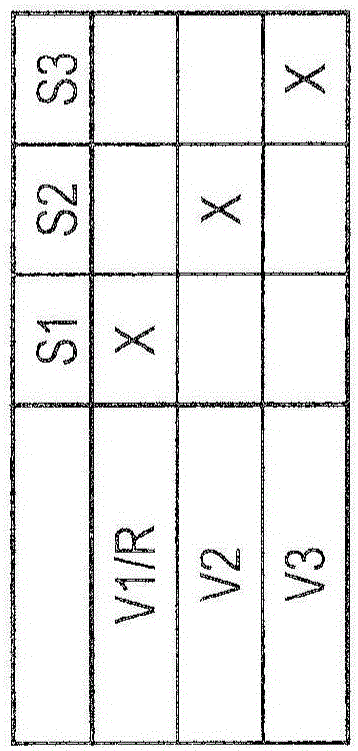

[0042] The torque provided by the drive machine 4 and present in the region of the transmission input shaft 2 can be directed via the first power path 5 and the second power path 6 through the transmission 1 in the direction of the transmission output shaft 7 , wherein In the first power path 5 there is a transmission 8 for changing the transmission ratio ivar of the first power path 5, and in the second power path 6 there is a mechanical transmission part 10 for achieving a constant transmission ratio ik, so the transmission The overall transmission ratio of the device 1 can be continuously varied in a desired range via the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com