Heat exchange enhanced pipe

A technology of reinforced tubes and round tubes, applied in heat exchange equipment, tubular elements, lighting and heating equipment, etc., can solve the problems of unfavorable energy saving, increased flow resistance, obstruction, etc., and achieve the effect of high energy saving and environmental protection efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

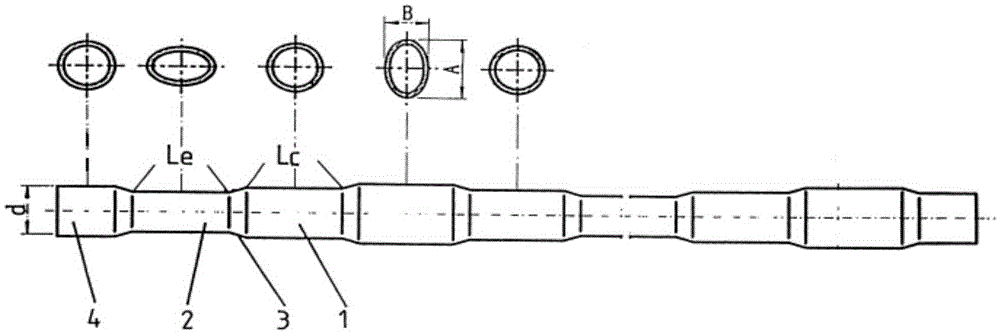

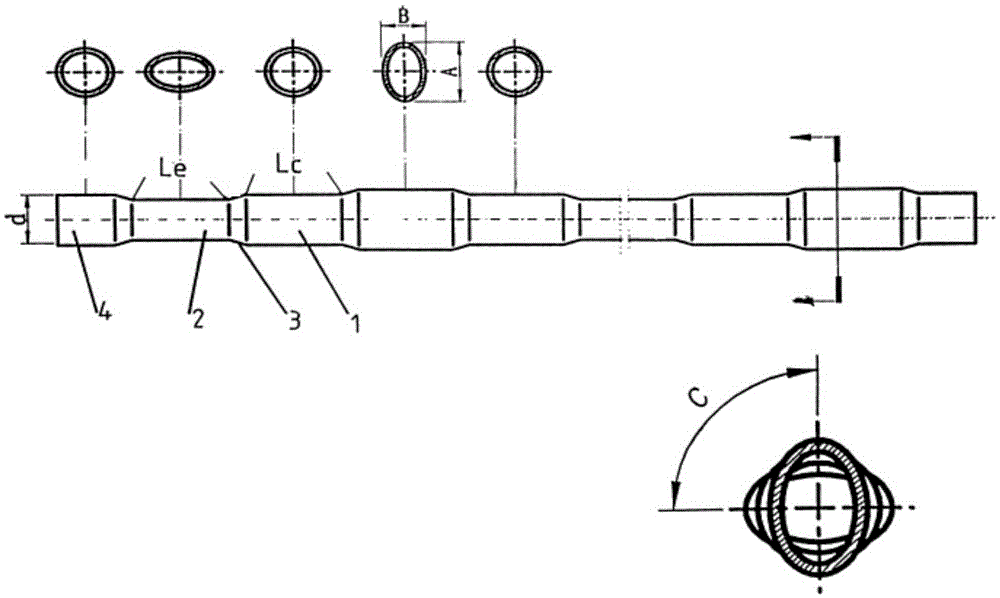

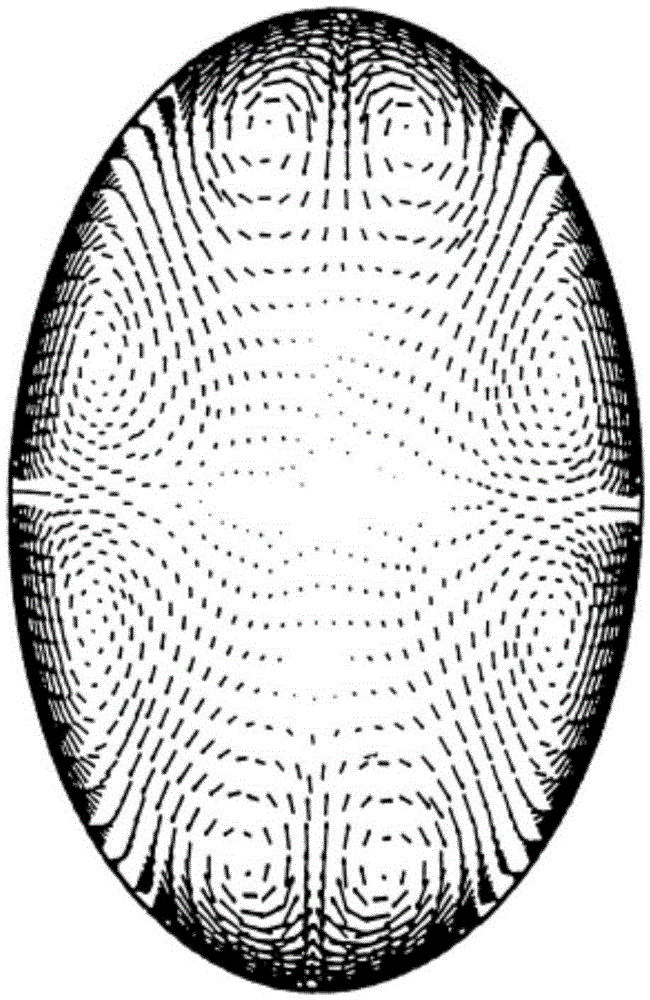

[0013] Such as figure 1 , figure 2 As shown, a heat exchange enhancing tube includes a circular tube section 1; the circular tube section 1 is connected to the elliptical tube section 2 through an elliptical transition section 3; each circular tube section 1 can be of equal or unequal length; each elliptical tube section 2 can be Equal or unequal length. The cross-section angle C of the major axis A of the ellipse of two adjacent elliptical pipe sections 2 is 15°-90°, and this angle is to increase the resistance generated when the liquid in the pipe flows. The cross-sectional shape of the elliptical transition pipe section 3 is a standard ellipse or an approximate ellipse or an oblate circle formed by two straight lines plus two arcs or a symmetrical and approximately symmetrical oblate circle or circle fitted by multiple arcs; each elliptical transition p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com