Smoke Control Method of Tamping Coke High Pressure Ammonia Water Pump

A technology of high-pressure ammonia water and stamping coke, which is applied in coking ovens, petroleum industry, charging devices, etc., can solve the difficulty of controlling smoke from coal charging in stamping coke ovens, smoke from chimneys cannot be effectively controlled, and affects the environment Factors such as prominent factors, to achieve the effect of solving the fluctuation problem of smoke from coal loading, reducing the labor intensity of employees, and reducing the probability of smoke from the chimney

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

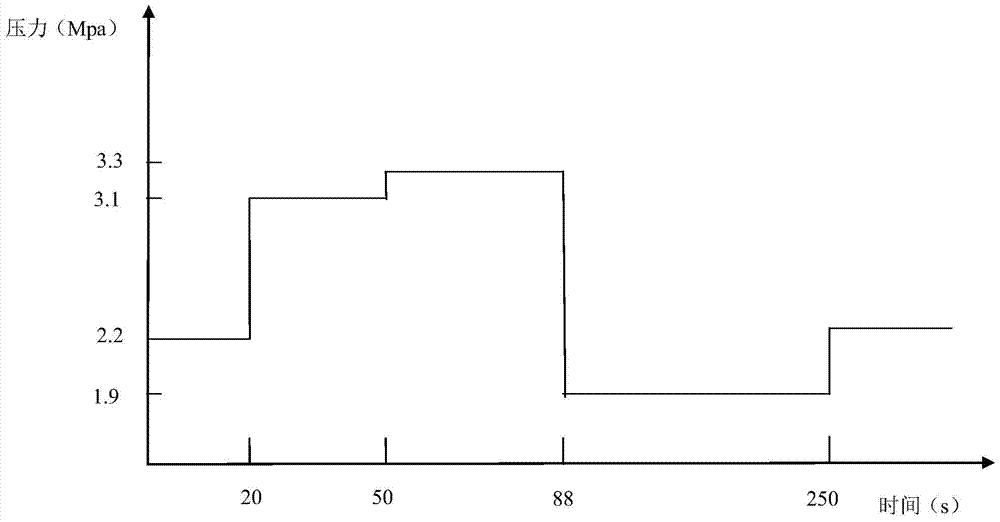

[0008] Such as figure 1 As shown, the present invention comprises the following steps: 1), when coal loading starts, the high-pressure ammonia water is controlled to be 2.2MPa by the frequency converter; 2), when the coal bottom plate advances for 20s, the high-pressure ammonia water control pressure is increased to 3.1MPa, At this time, the amount of raw gas production begins to increase; 3) When the coal bottom plate is moved forward for 50s, the high-pressure ammonia water control pressure is increased to 3.3MPa. At this time, the production of raw gas begins to increase further, and the production of raw gas starts from 50s to 80s. Maximum; 4), when the coal bottom plate moves forward for 88s, reduce the high-pressure ammonia water control pressure to 1.9MPa; 5), when the coal bottom plate moves forward for 250s, increase the high-pressure ammonia water control pressure to 2.2MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com