Large wheel diameter swing twist skateboard

A twist-type, large-diameter technology, which is applied in the field of entertainment products, can solve the problems of high ground requirements, sensitive ground impact, and laborious swinging, and achieve the effects of weight reduction, lower center of gravity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

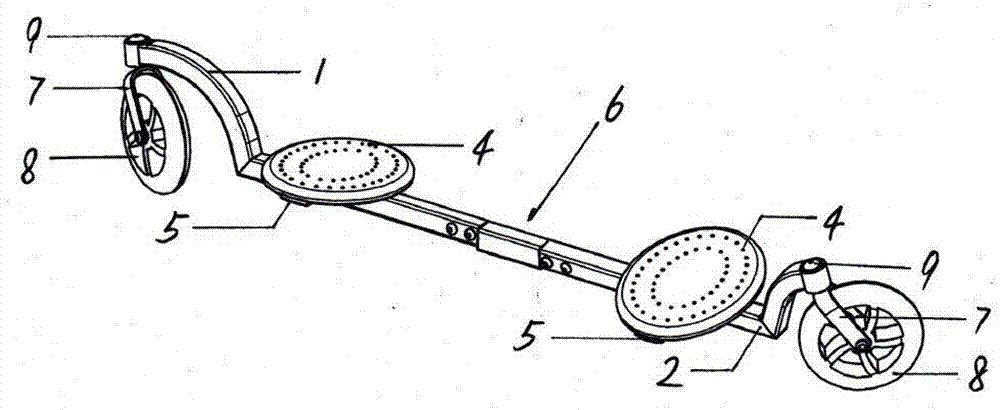

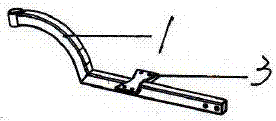

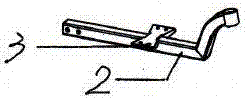

[0017] according to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the large wheel diameter swing and twist type skateboard includes a front frame 1, a rear frame 2, a pedal connector 3, a pedal 4, an anti-wear bottom strip 5, a wheel fork bearing, a swing and twist mechanism 6, and a wheel fork with a shaft. 7. PU wheel 8 and insert dome cover 9;

[0018] The front frame 1 includes a front arc tube, a front beam tube and a rotating cylinder. The front arc tube is bent into an arc shape by a rectangular tube, and the upper and lower sides of the front end of the front arc tube have arc openings. The arc opening at the front end of the front arc tube corresponds to the diameter of the drum, the lower end of the front arc tube is cut into a bevel, and the bevel at the lower end of the front arc tube is welded to the front beam tube, The front beam tube is made of a rectangular tube, the front end of the front beam tube is cut into oblique openings, and there ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com