Method for designing car front longitudinal beam with hat section

A design method, the technology of the front longitudinal beam, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problem of the lack of overall planning of the overall deformation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

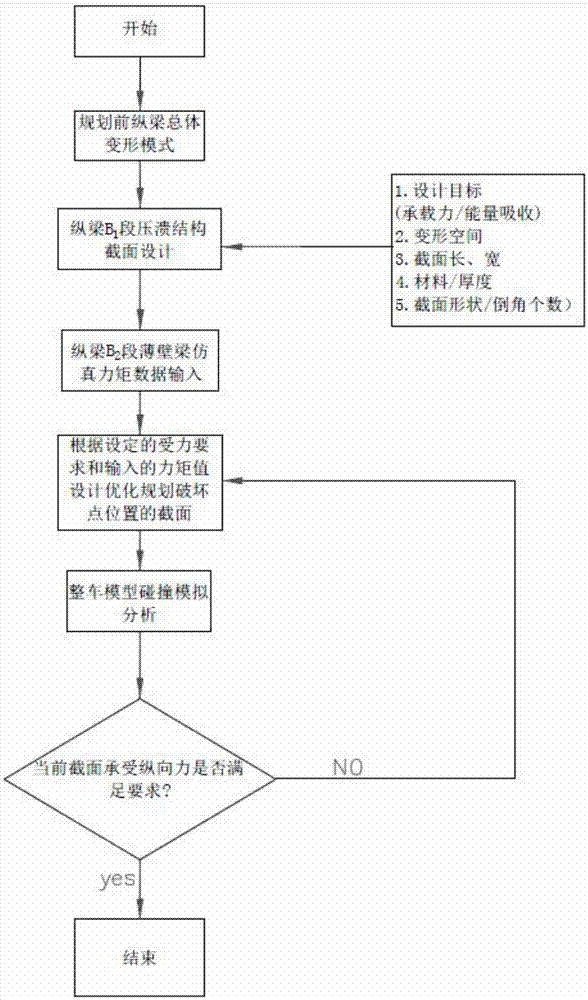

[0120] Adopt the automobile front longitudinal beam design method of the hat-shaped section of the present embodiment to design the process of a certain automobile front longitudinal beam as follows:

[0121] 1. Plan the overall deformation mode of the front longitudinal beam under the frontal collision condition:

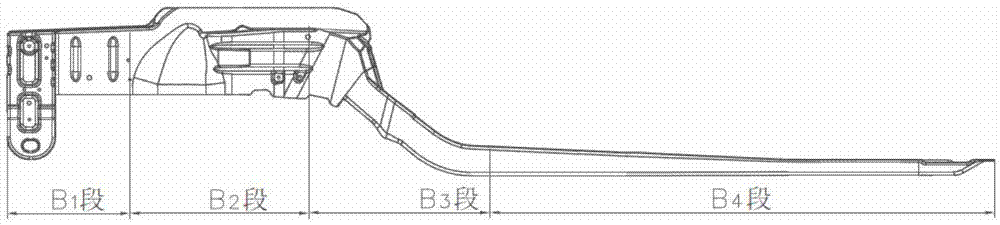

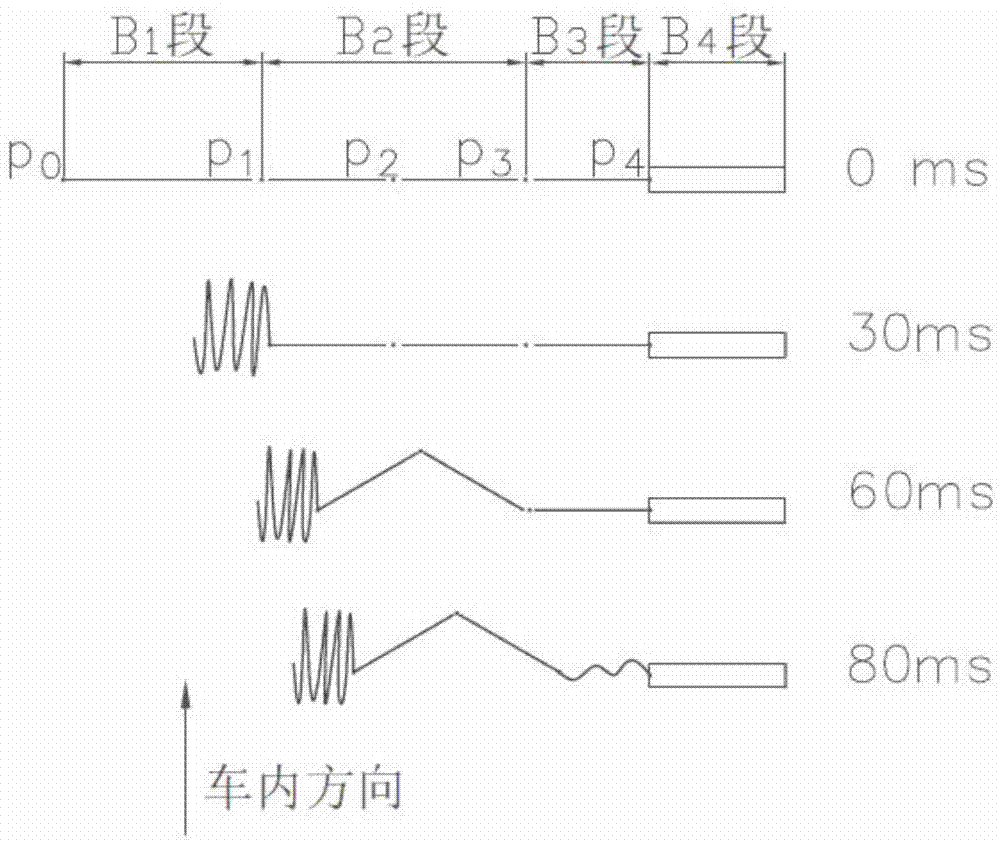

[0122] The deformation mode planning of the front longitudinal beam is generally as follows: figure 2 Shown: Section B1 is stable in telescopic compression; Section B2 is bent in the Y direction in the plane; Section B3 is as small as possible in bending deformation; Section B4 is not deformed and matches the strength of the body floor.

[0123] 2. Deduce the expression of the average crushing reaction force of thin-walled beams with hat-shaped cross-section:

[0124] According to the derivation process in the specific implementation, the expression of the average crushing reaction force of the hat-shaped thin-walled beam is obtained as

[0125] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com