Liquid soap bag

A technology of soap liquid and liquid spout, which is applied in the improvement field proposed by the traditional soap dispenser, and can solve the problems of single structure, poor stability and easy leakage of the liquid container and spout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

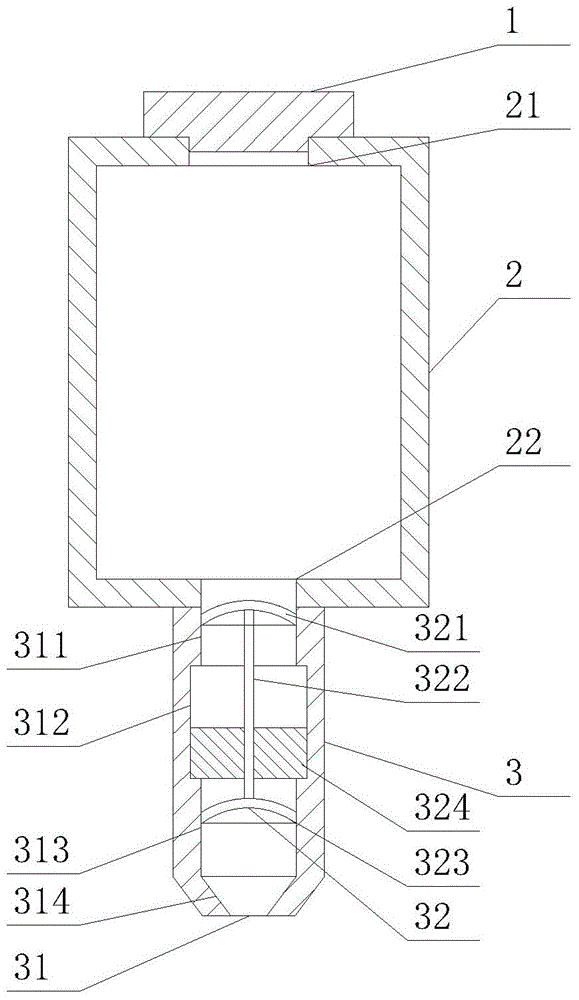

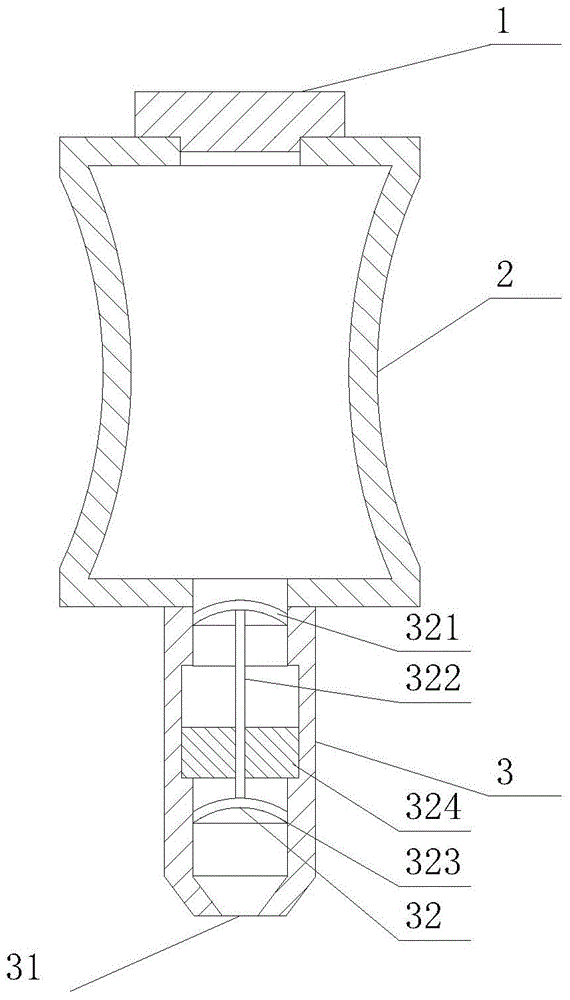

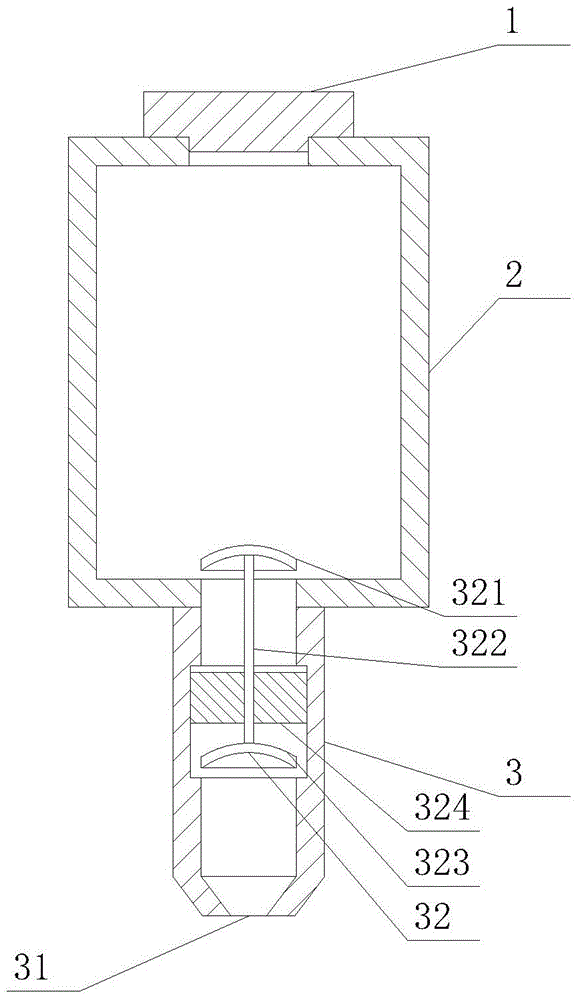

[0016] The present invention as Figure 1-3 As shown, it includes a storage bag 2, a cover 1 and a liquid outlet 3, the top surface of the storage bag 2 has a liquid inlet 21, and the bottom surface has a liquid outlet 22, and the cover 1 is detachable connected to the liquid inlet 21, the liquid outlet 3 communicates with the liquid inlet 22, and is fixedly connected to the bottom surface of the storage bag 2;

[0017] The liquid outlet nozzle 3 includes a pipe body 31 and a core body 32, the pipe body 31 is provided with a stepped hole, and the core body 32 is accommodated in the stepped hole;

[0018] The core body 32 includes a first elastic piece 321, a connecting rod 322, a second elastic piece 323 and a plurality of support plates 324. Both the first elastic piece 321 and the second elastic piece 323 are in the shape of an umbrella surface protruding upward, and are fixedly connected respectively. At the upper and lower ends of the connecting rod 322, several support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com