sn-scm-3 zeolite molecular sieve and preparation method thereof

A technology of molecular sieves and molar ratios, applied in molecular sieves and base exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

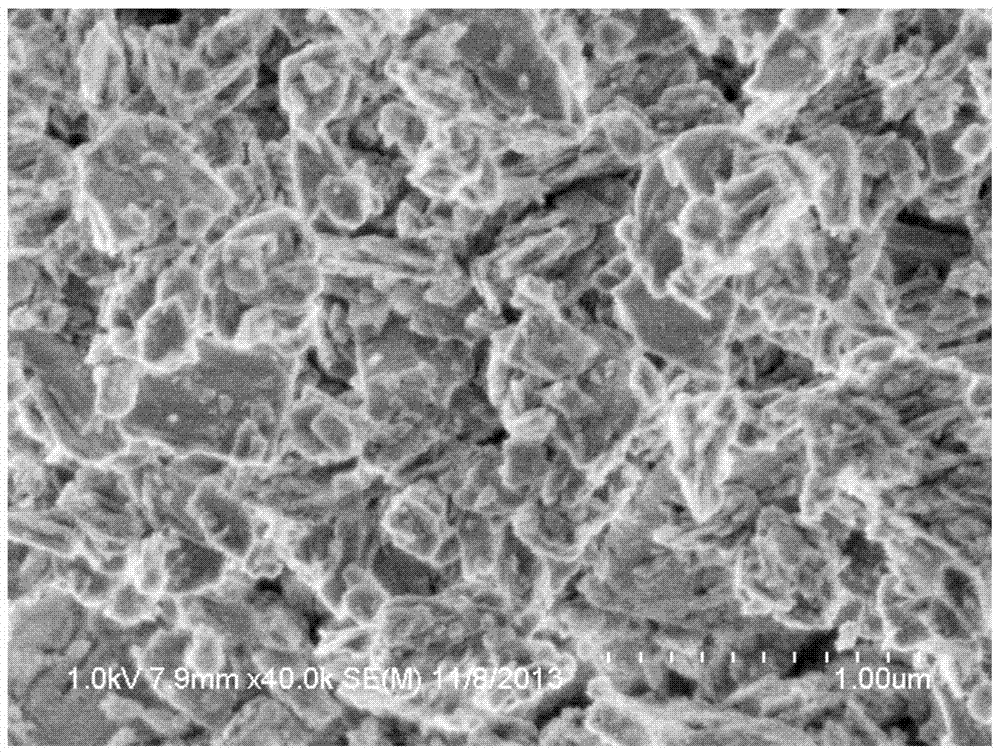

Image

Examples

Embodiment 1

[0040] 1 gram of Kenyaite material with a molar ratio of B2O3 / SiO2 of 0.04 was mixed with 20 milliliters of 0.1M hydrochloric acid, stirred at 20°C for 24 hours, washed, solid-liquid separated and dried to obtain a hydrochloric acid-treated solid product, and 2 grams The Kenyaite obtained by hydrochloric acid treatment was mixed with 0.045 g of stannous oxalate and ground, and the solid mixture after grinding was roasted at 600°C for 5 hours to obtain Sn-SCM-3 molecular sieve, whose X-ray diffraction lines are shown in Table 1. In the product, Sn The / Si molar ratio was 0.006.

Embodiment 2

[0042] 1 gram of Kenyaite material with a molar ratio of B2O3 / SiO2 of 0.04 was mixed with 20 milliliters of 10M hydrochloric acid, stirred at 20°C for 24 hours, washed, solid-liquid separated and dried to obtain a hydrochloric acid-treated solid product. The Kenyaite obtained by hydrochloric acid treatment was mixed with 0.089 g of stannous oxalate and ground, and the solid mixture after grinding was roasted at 600°C for 5 hours to obtain Sn-SCM-3 molecular sieve, whose X-ray diffraction line was similar to Table 1. In the product, Sn / Si The molar ratio is 0.009.

Embodiment 3

[0044] 1 gram of Kenyaite material with a molar ratio of B2O3 / SiO2 of 0.04 was mixed with 20 milliliters of 10M hydrochloric acid, and airtightly stirred at 100°C for 24 hours. After washing, solid-liquid separation and drying, the hydrochloric acid-treated solid product was obtained. 2 grams The Kenyaite obtained by hydrochloric acid treatment was mixed with 0.089 gram of stannous oxalate and ground, and the ground solid mixture was roasted at 600° C. for 5 hours to obtain Sn-SCM-3 molecular sieve, whose X-ray diffraction line was similar to Table 1. In the product, Sn / The molar ratio of Si is 0.013.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com