Multi-purpose assembly fixture for skewed laminated rotor core assembly

A technology of rotor iron core and assembling fixture, which is applied in workpiece clamping devices, manufacturing tools, metal processing and other directions, can solve the problems of complicated operation, complex structure, and troublesome mold removal, and achieves convenient assembly, accurate skew angle, and retractable Easy and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

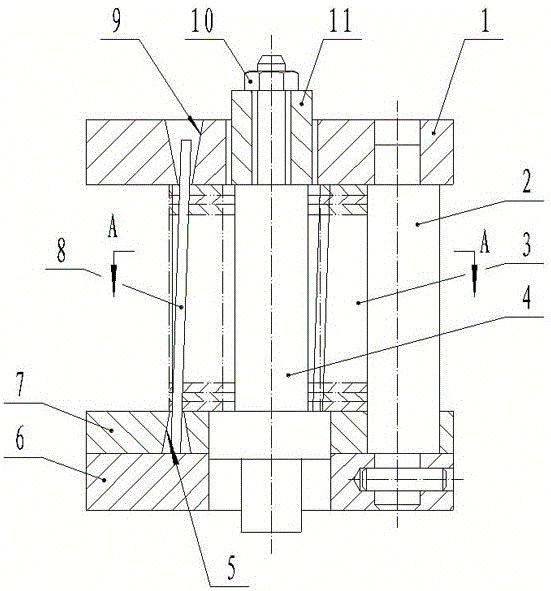

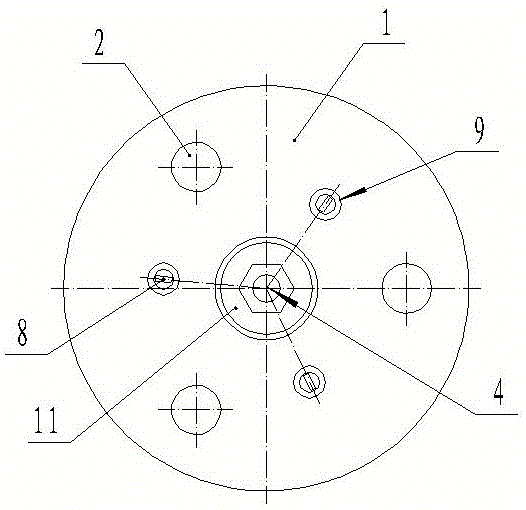

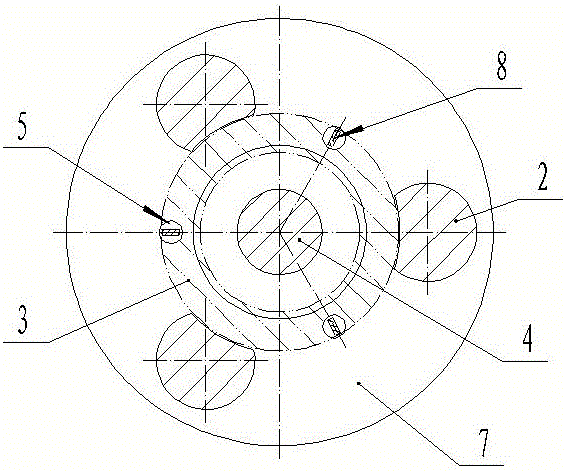

[0016] as attached Figure 1-7 As shown, the backing plate 7 is fixed on the base 6, and there are through holes on the backing plate 7 and the base 6; three positioning columns 2 are fixed on the base 6 with the center of the backing plate 7 as the center of the circle, and the pressing plate 1 is positioned on the positioning column 2 superior. The pressure plate 1 has three first speaker holes 9 with upper and lower dimensions evenly distributed around the center, and the backing plate 7 has three second speakers with upper and lower dimensions evenly distributed around the center. Hole 5, the first horn hole 9 and the corresponding second horn hole 5 are staggered clockwise or counterclockwise by 12º18´ with the center as the center; the pin 8 is inserted in the corresponding first horn hole 9 and the second horn hole 5 Between, there is cleara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com