A Speed Tracking System of Rotating Mechanism

A technology of rotating mechanism and tracking system, applied in the direction of control system, vector control system, electromechanical device, etc., can solve the problems affecting the work efficiency and achieve the effect of smooth switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

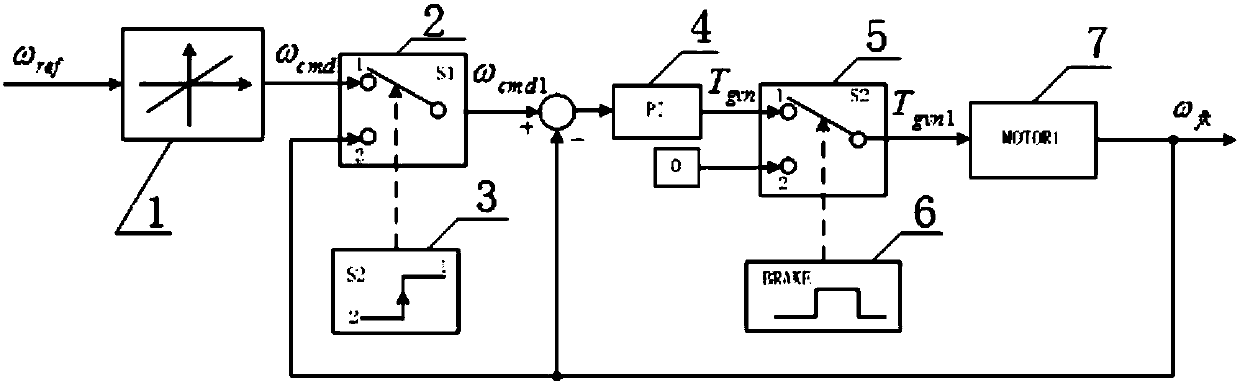

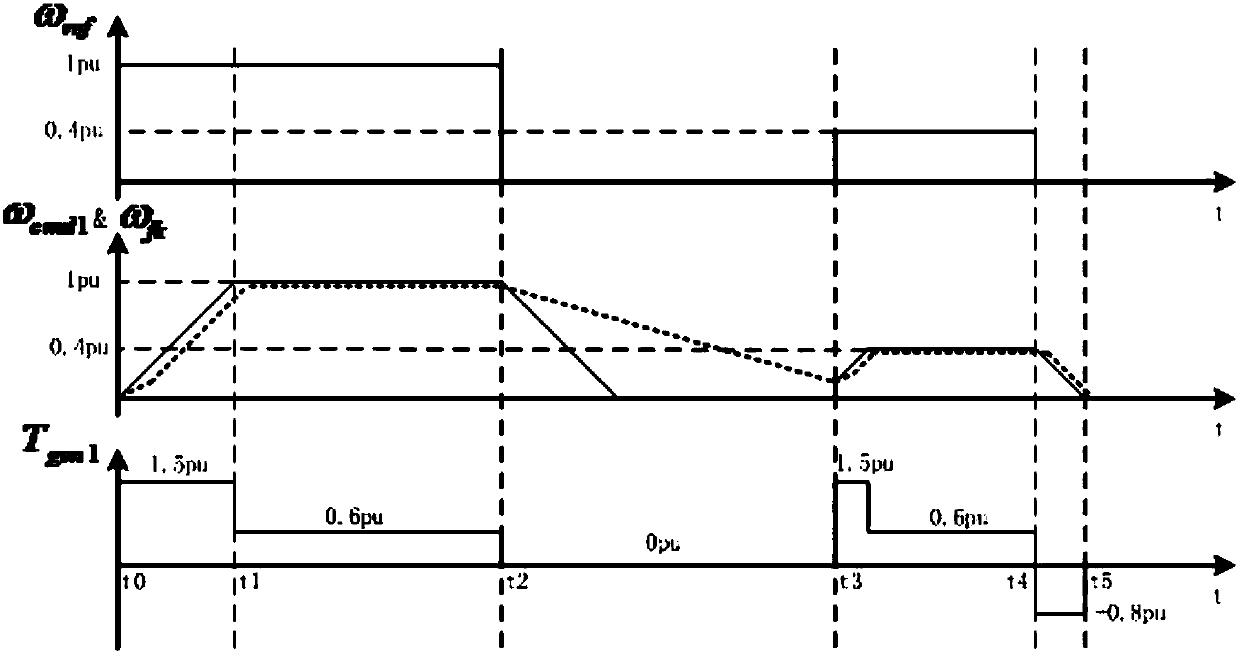

[0019] A speed tracking system for a rotating mechanism ( figure 1 ), including a slope conversion unit 1, a first switch 2, a PI regulator 4, a second switch 5 and a motor 7;

[0020] Speed command reference value ω ref The slope conversion unit 1 generates the first rotation speed command value ω whose rate of change can be set cmd ;

[0021] The first changeover switch 2 receives the first rotational speed command value ω cmd and motor 7 speed feedback value ω fk , output the second rotational speed command value ω cmd1 , the second speed command value ω is controlled by the second switch state 3 signal cmd1 Equal to the first rotational speed command value ω cmd Or motor 7 speed feedback value ω fk ; When the second switch 5 is in the control state of the frequency converter, the second switch 5 feedbacks the value ω from the speed of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com