Cleaning device of automatic cleaning machinery

A cleaning device and automatic cleaning technology, applied in cleaning machinery, manual sweeping machinery, cleaning equipment, etc., can solve problems such as inability to effectively spray the surface to be cleaned, leaving water stains on the surface to be cleaned, and prone to splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

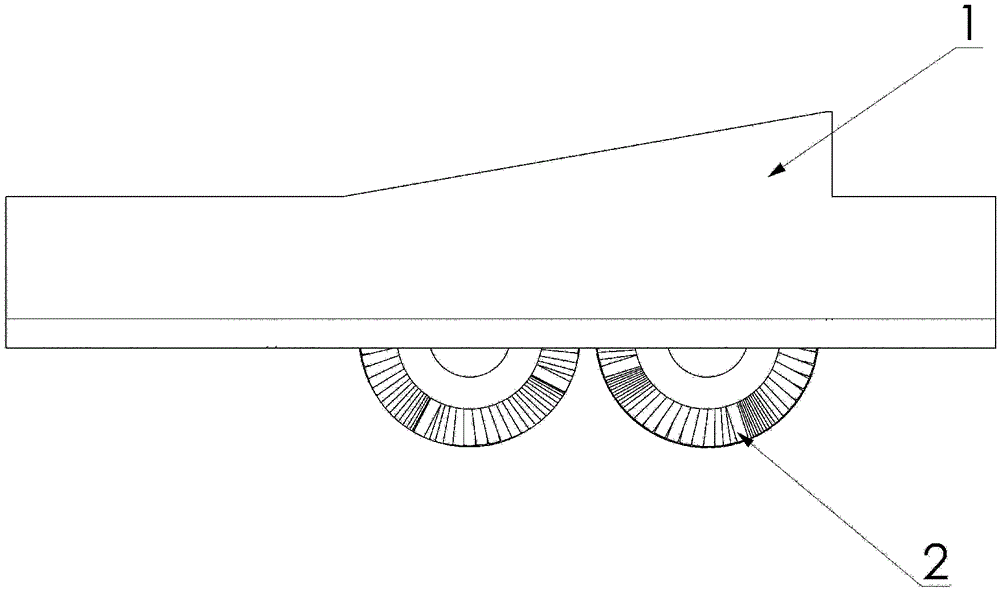

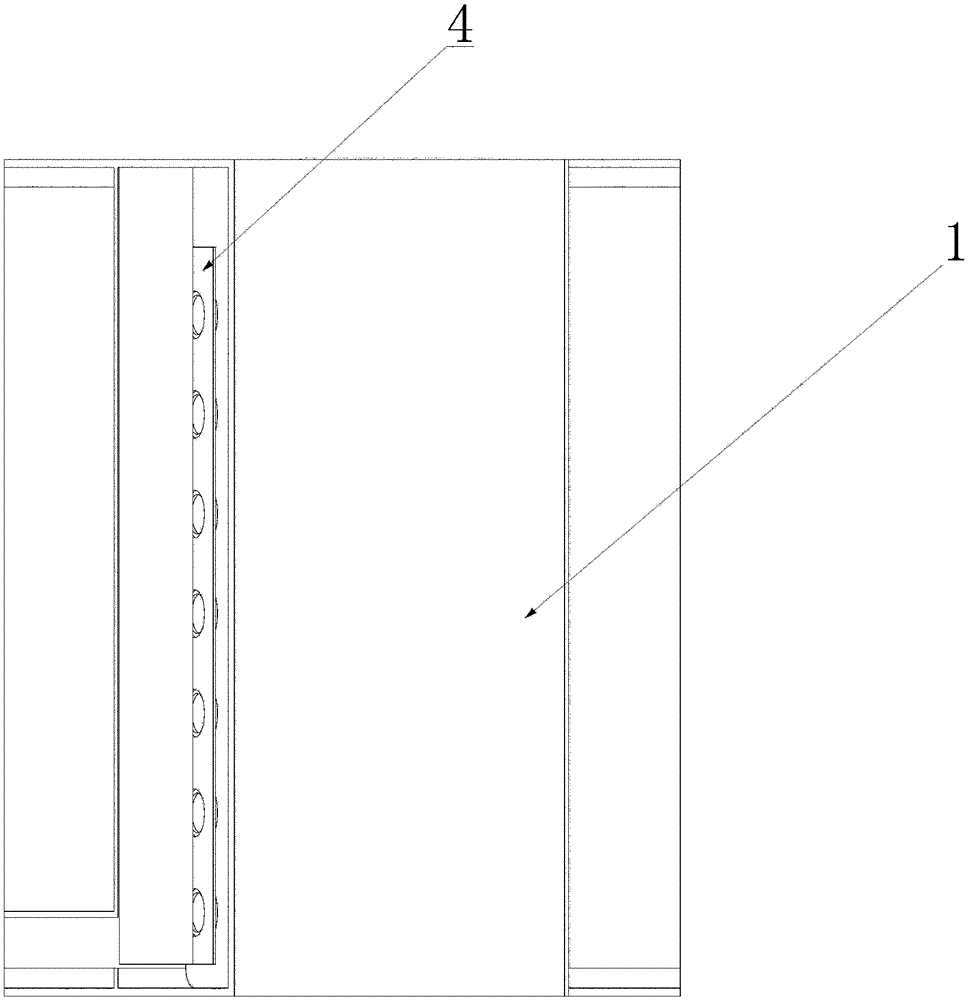

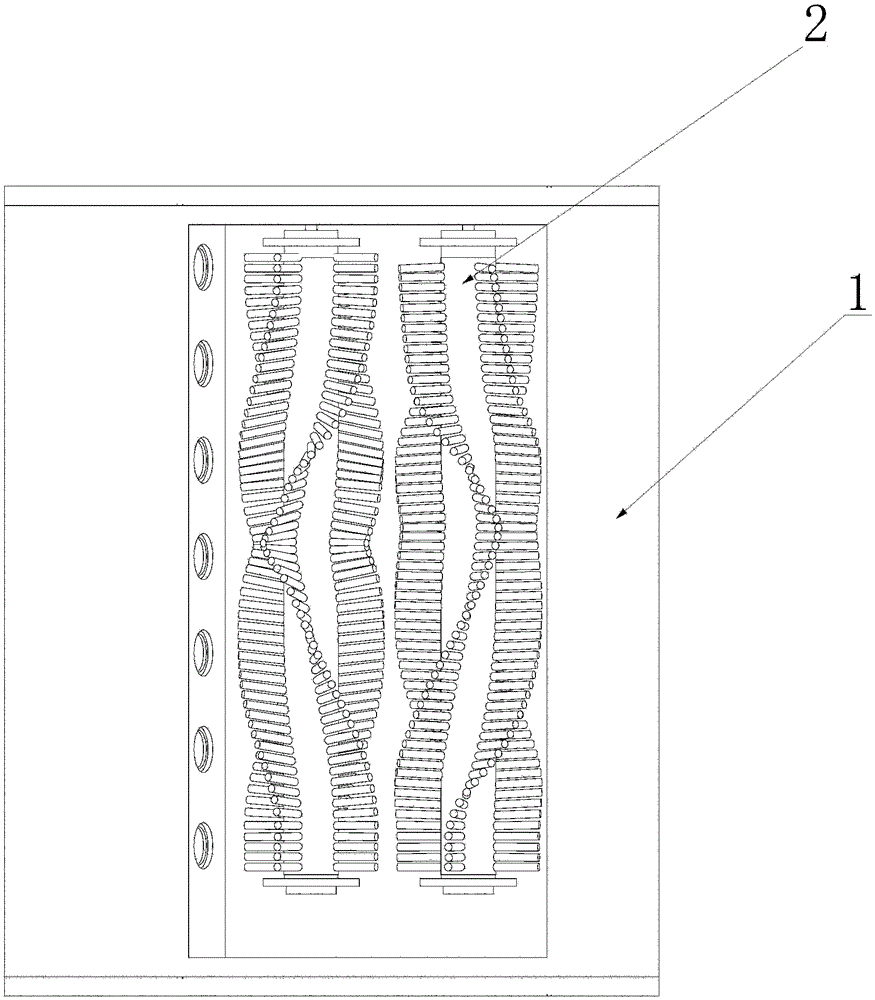

[0022] The cleaning device in this embodiment is mainly composed of a brush roller 2, a microporous atomizing sheet 3, and a housing 1;

[0023] like Figure 10 As shown, when the device mainly moves horizontally (such as a mopping machine), the cleaning liquid flows through the groove where the capillary liquid guide strip 5 is located and fills it to a suitable height, and the capillary liquid guide strip 5 acts as a liquid guide in the device , also play a role in preventing excessive cleaning liquid from overflowing the device in a flowing state, or use the capillary liquid guide strip 5 to contact the microporous atomizing sheet 3 to transfer the cleaning liquid; when the device is not mainly based on horizontal movement (such as wiping Glass robot, curtain wall cleaning), the cleaning liquid is mainly transferred to the microporous atomizing sheet 3 through the contact of the capillary liquid guide strip 5 and the microporous atomizing sheet 3; Figure 10 The middle arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com