Test method for weatherability of exterior finishes

A test method and weather resistance technology, which is applied in the field of performance testing of exterior topcoats, can solve the problems of large deviation of test data, high cost, and incompleteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

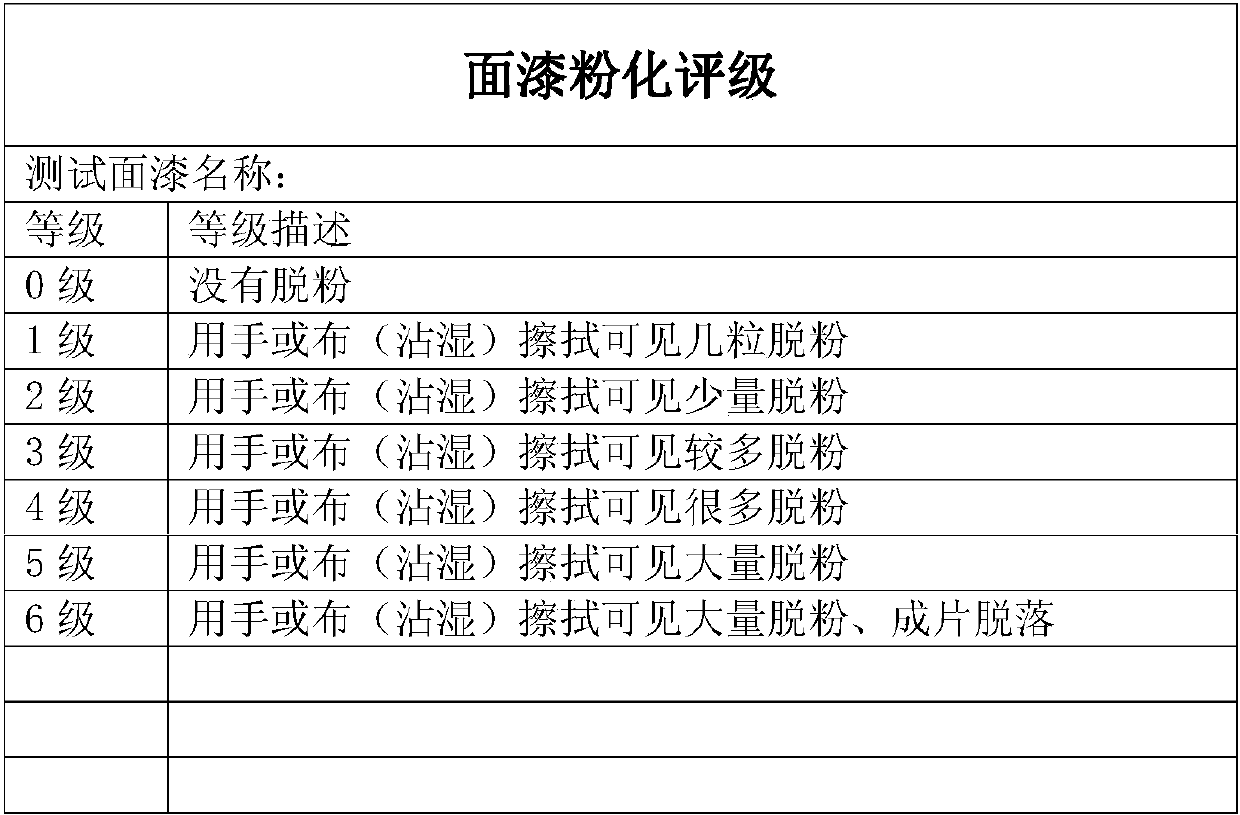

Method used

Image

Examples

Embodiment 1

[0036] The test object of the present embodiment is a kind of adjustable finish paint with a contrast ratio of 0.89, comprising the following steps:

[0037] Step 1: Batch scraping putty layer: Prepare 4 test panels, scrape putty layer on each test panel and cure for 24 hours, then rinse each test panel with water, and proceed to the next step after the putty layer on each test panel is dry;

[0038] Step 2: Apply primer: apply a primer that matches the topcoat to be tested on the putty layer of each test panel, then let each test panel dry for 18 hours, and proceed to the next step after the primer on each test panel is dry. step;

[0039] Step A: coloring of the topcoat: mixing 96 parts by weight of the topcoat to be tested with 2 parts by weight of color paste to obtain the topcoat to be tested;

[0040] Step B: Apply topcoat: Divide the surface of the test panel into two areas, apply a toned topcoat to be tested in one area, and apply an untinted topcoat to be tested in t...

Embodiment 2

[0056] The test object of the present embodiment is a kind of adjustable finish paint with a contrast ratio of 0.53, comprising the following steps:

[0057] Step 1: Batch scraping putty layer: Prepare 7 test panels, scrape putty layer on each test panel and cure for 36 hours, then rinse each test panel with water, and proceed to the next step after the putty layer on each test panel is dry;

[0058] Step 2: Apply primer: apply a primer that matches the topcoat to be tested on the putty layer of each test panel, then let each test panel dry for 20 hours, and proceed to the next step after the primer on each test panel is dry. step;

[0059] Step A: coloring of the topcoat: mixing 90 parts by weight of the topcoat to be tested with 10 parts by weight of the bright red paste to obtain the topcoat to be tested;

[0060] Step B: Apply topcoat: Divide the surface of the test panel into two areas, apply the toned topcoat to be tested in one area, and apply the non-tinted topcoat to...

Embodiment 3

[0076] The test object of the present embodiment is a kind of non-colorable finish paint, comprises the following steps:

[0077] Step 1: Batch scraping putty layer: Prepare 11 test panels, scrape putty layer on each test panel and cure for 42 hours, then rinse each test panel with water, and proceed to the next step after the putty layer on each test panel is dry;

[0078] Step 2: Apply primer: apply a primer that matches the topcoat to be tested on the putty layer of each test panel, then let each test panel dry for 22 hours, and proceed to the next step after the primer on each test panel is dry. step;

[0079] Step 3: Apply the topcoat to be tested: apply the topcoat to be tested on the primer of each test panel and cure for 144 hours, and proceed to the next step after the topcoat to be tested on each test panel is dry;

[0080] Step 4: Exposure test: Place one test panel in a dark place indoors as a blank control, and place the rest of the test panels on the exposure si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com