Rotary elastomer and grinding-polishing equipment

A technology of elastic body and elastic body, which is applied in the field of polishing equipment and grinding, can solve the problems of high grinding and polishing speed, complex removal function of grinding and polishing trajectory, low maintenance of processing accuracy, and low processing efficiency, so as to achieve controllable material removal rate , remove the effect of ideal function and high processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

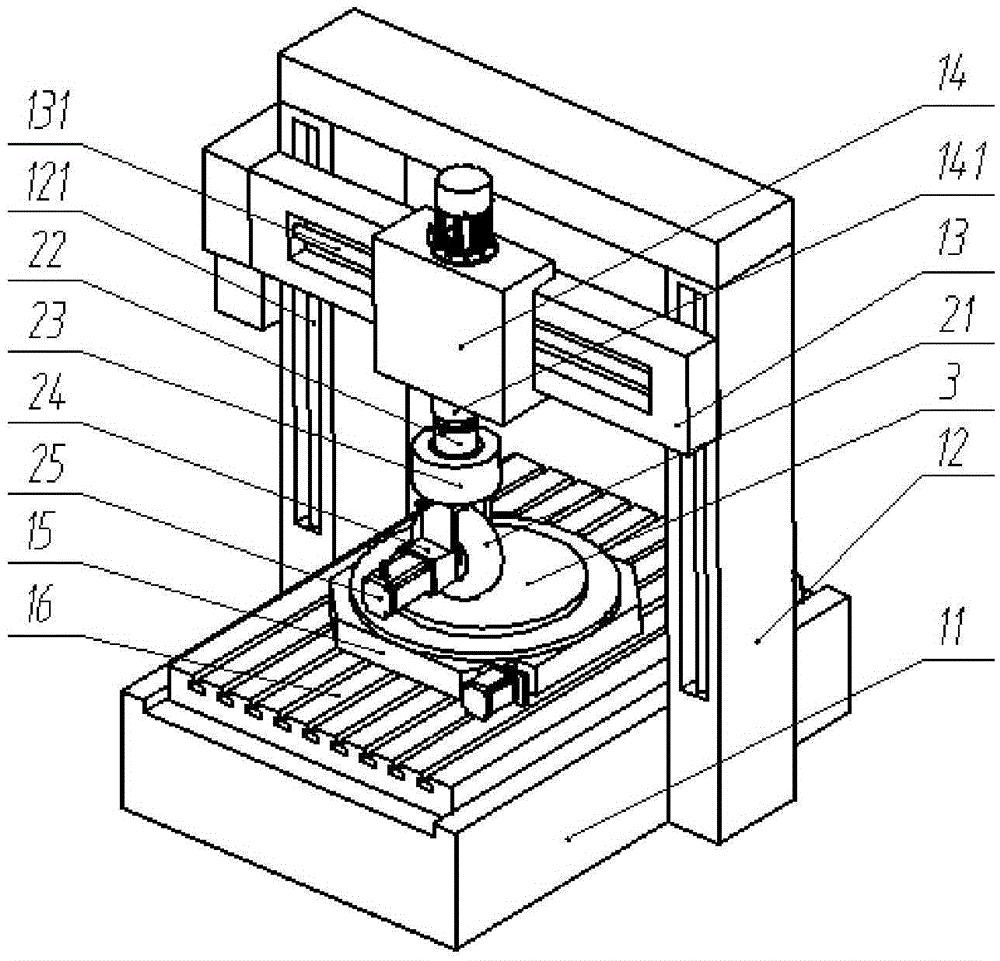

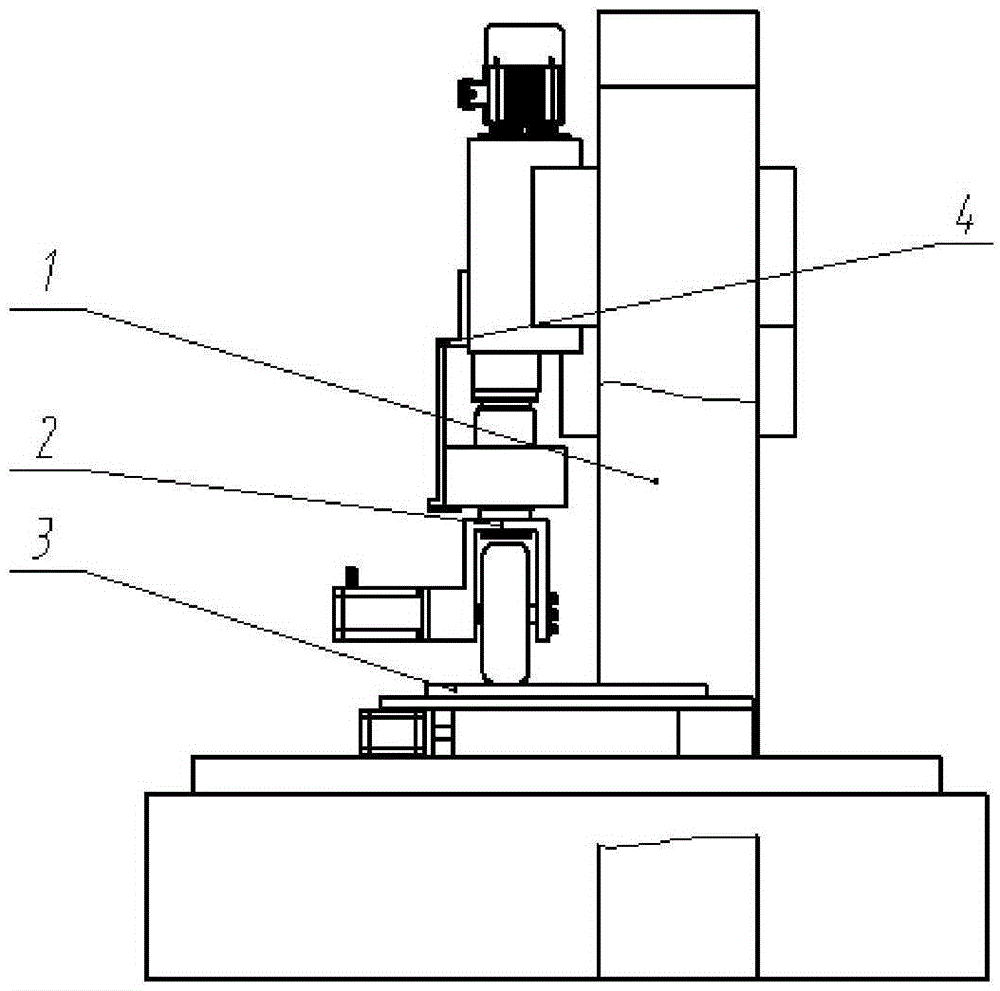

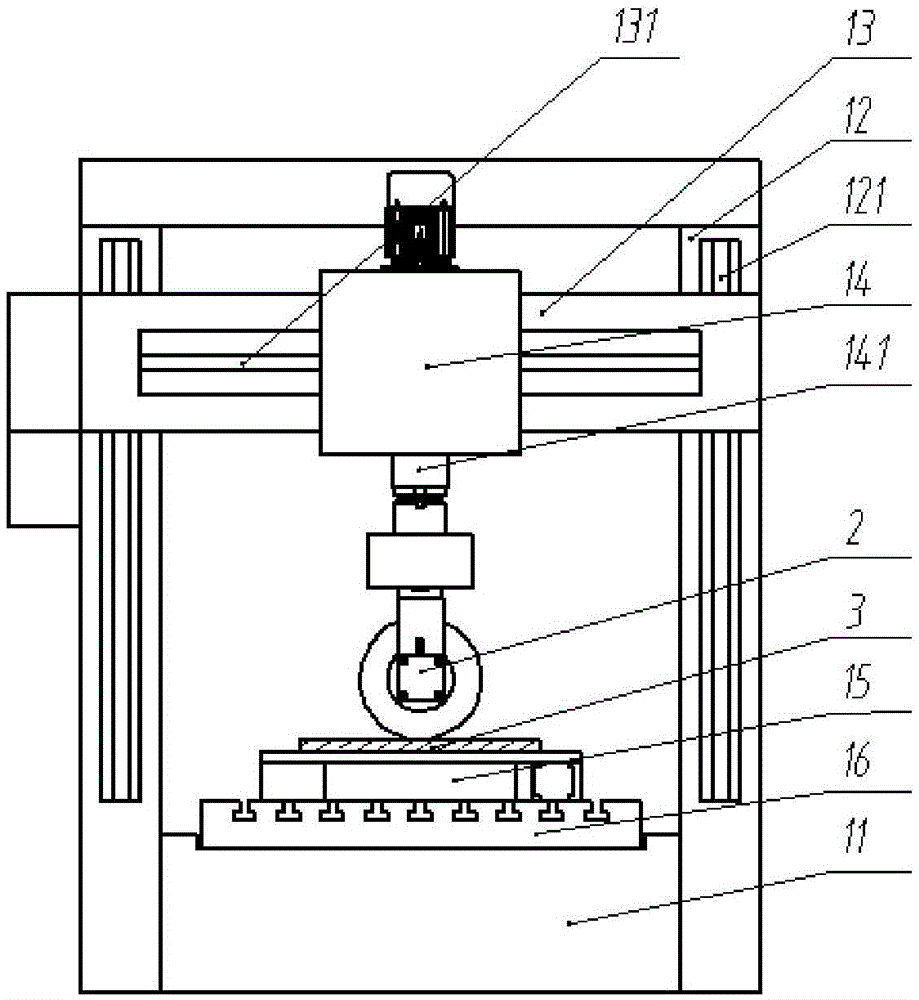

[0033] A rotary elastomer grinding and polishing equipment, such as Figure 1-Figure 4 As shown, it includes a machine tool body 1 and a rotary elastic body polishing device 2. The upper part of the rotary elastic body polishing device 2 is connected to the spindle head 141 through a connecting handle 22, and can be driven by the spindle head 141 to rotate. A rotary table 15 is installed on the slide table 16 above the bottom base 11 of the machine tool body 1 . The workpiece 3 is installed on the rotary table 15 , and the surface to be processed on the workpiece 3 is in contact with the lower part of the rotary elastic body 21 . The rotary table 15 can drive the workpiece 3 to rotate. The slide table 16 can drive the rotary table 15 to translate. The spindle box 14 can move up and down with the beam 13 under the action of the column transmission mechanism 121 on the column 12 . The spindle box 14 can move left and right under the action of the beam transmission mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com